© Nov. 2020 7-6 GTTZ10EJ Operation Manual

OPERATING THE MACHINE

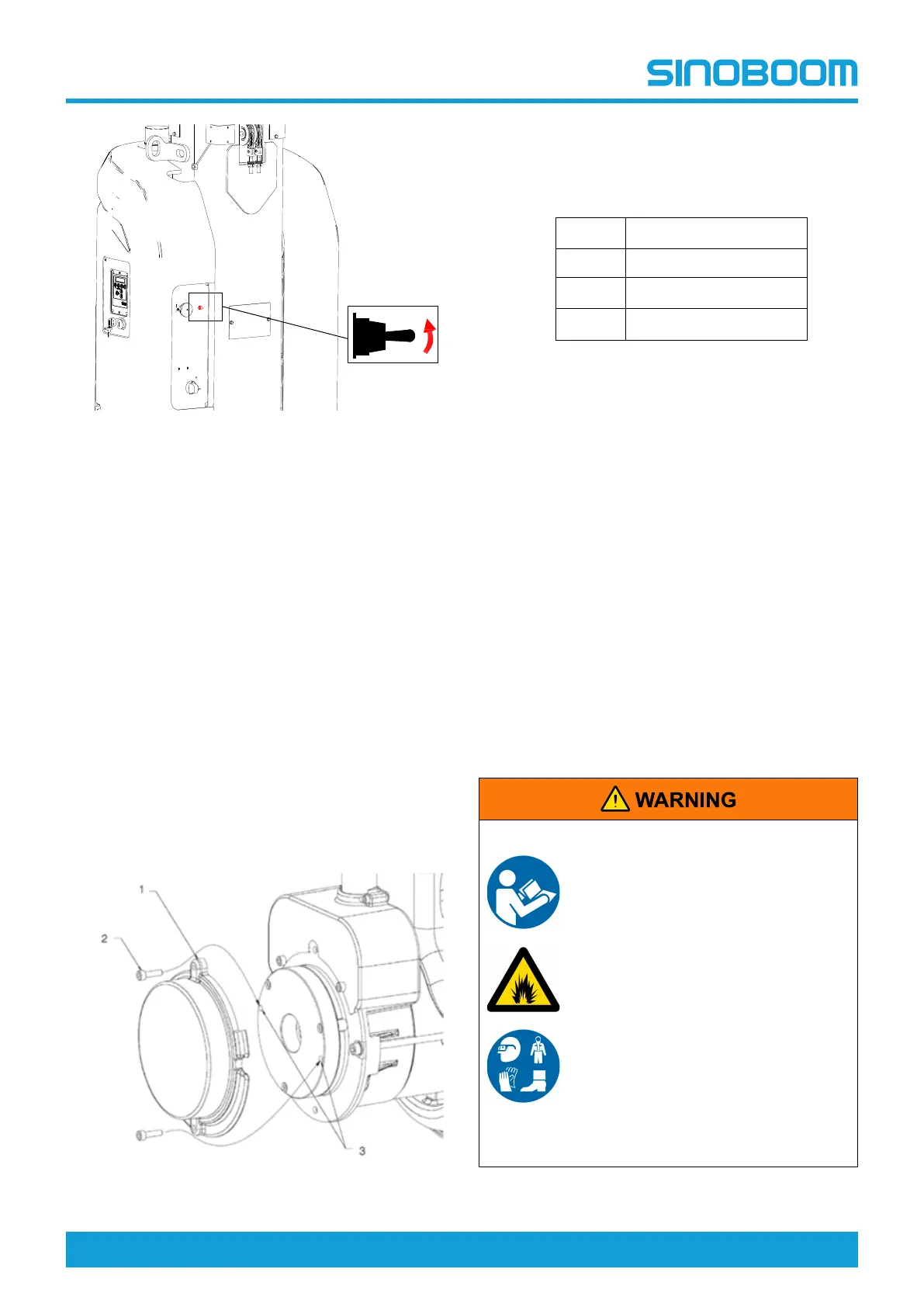

Figure 7-7

4. When a beef sounds, it indicates the brake is

released and the machine is all set for the towing/

dragging.

5. After the towing/dragging is complete, position the

machine on a firm level surface.

6. Choke wheels securely to prevent motion of the

machine.

7. Move again the brake release switch, or push in the

emergency stop button, or turn the key switch to off

position, to engage the brake.

8. Remove the chokes as desired.

Method 2:

1. Choke wheels securely to prevent motion of the

machine.

2. Be sure the path is clear of obstructions, and the

power disconnect switch in off position.

3. Remove the both end cap bolts and brake cover

from the wheel reducer.

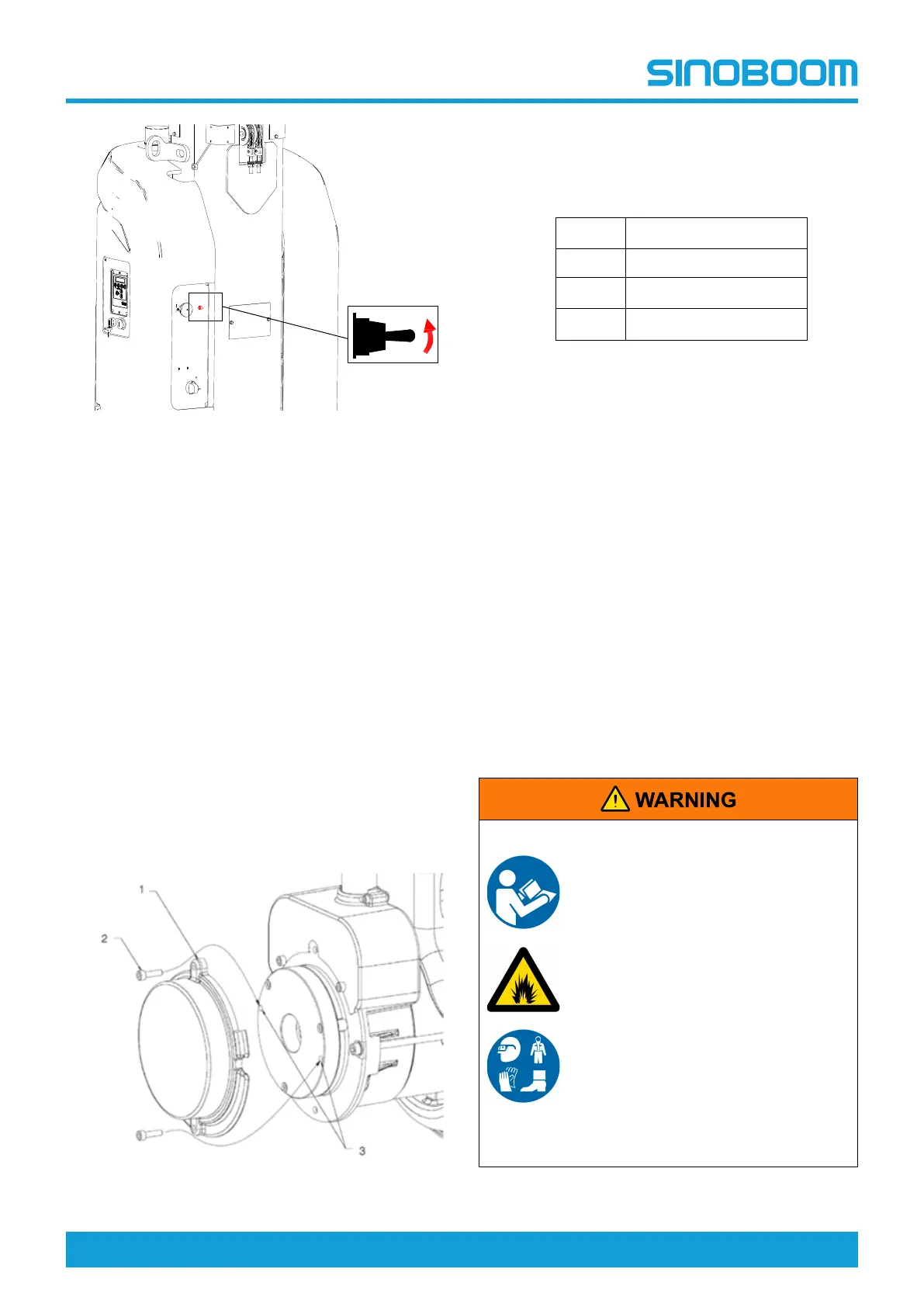

Figure 7-8

Table 7-1

No.

Description

1 Brake cover

2

End cap bolt

3

Disengage hole

4. Insert the end cap bolts into the both disengage

holes on the brake housing.

5. Tighten the bolts to disengage the brake from the

drive motor.

6. Repeat the procedure above to the other wheel

reducer. After the both brakes are disengaged from

the drive motors, the machine is all set for the

towing/dragging.

7. After the towing/dragging is complete, position the

machine on a firm level surface.

8. Choke the wheels to prevent the machine from

rolling.

9. Remove the end cap bolts from the disengage

holes, and install the brake cover and end cap

bolts.

10. Remove the chokes as desired.

CHARGING THE BATTERY

BATTERY HAZARDS

Always read and comply with the bat-

tery manufacturer’s recommenda-

tions for procedures concerning

proper battery use and maintenance.

Batteries contain sulfuric acid and

generate explosive mixtures of hy-

drogen and oxygen gases. Keep any

device that may cause sparks or

flames away from the battery to pre-

vent explosion.

Always wear protective glasses or

goggles and protective clothing

when working with batteries. You

must follow the battery manufac-

turer’s instructions on safety, mainte-

nance and installation procedures.

There are three types of batteries:

Loading...

Loading...