9

Assume proper operating position;

- at the front of the saw;

- in front of the saw;

- to the left of the line of cut;

- if working with two persons the second person

should stand at a rear table extension.

If the type of work requires, use the following;

- table extension if working with two persons or if

otherwise work-pieces would fall off the saw

table;

- dust collector.

Avoid typical operator mistakes;

- Do not attempt to stop the saw blade by

pushing the work-piece a against its side.

Risk of kickback.

- Always hold the work-piece down on the

table and do not jam it. Risk of kickback.

- Never cut several work-pieces at the same

time – and also no bundles containing

several individual pieces. Risk of personal

injury if individual pieces are caught by the

saw blade uncontrolled.

Drawing-in/trapping hazard!

Never cut stock to which ropes, cords, strings,

cables or wires are attached or which contain

such material.

9.1 Sawing

For cutting the work-piece is evenly fed against the saw

blade towards the rear of the table:

1. Set depth of cut. The blade guard must be rest with its

front edge on the work-piece.

2. Set blade tilt and lock in position.

3. Mount rip fence, if required.

4. Start saw.

5. Cut work-piece in a single pass.

6. Switch machine off if no further cutting is to be done

immediately afterwards.

9.2 Mitre cuts

1. Fit mitre fence to the table slot.

2. Loosen lock knob, set to desired angle with the

indicator and tighten lock knob again.

3. Cut work-piece by pushing the mitre fence-forward.

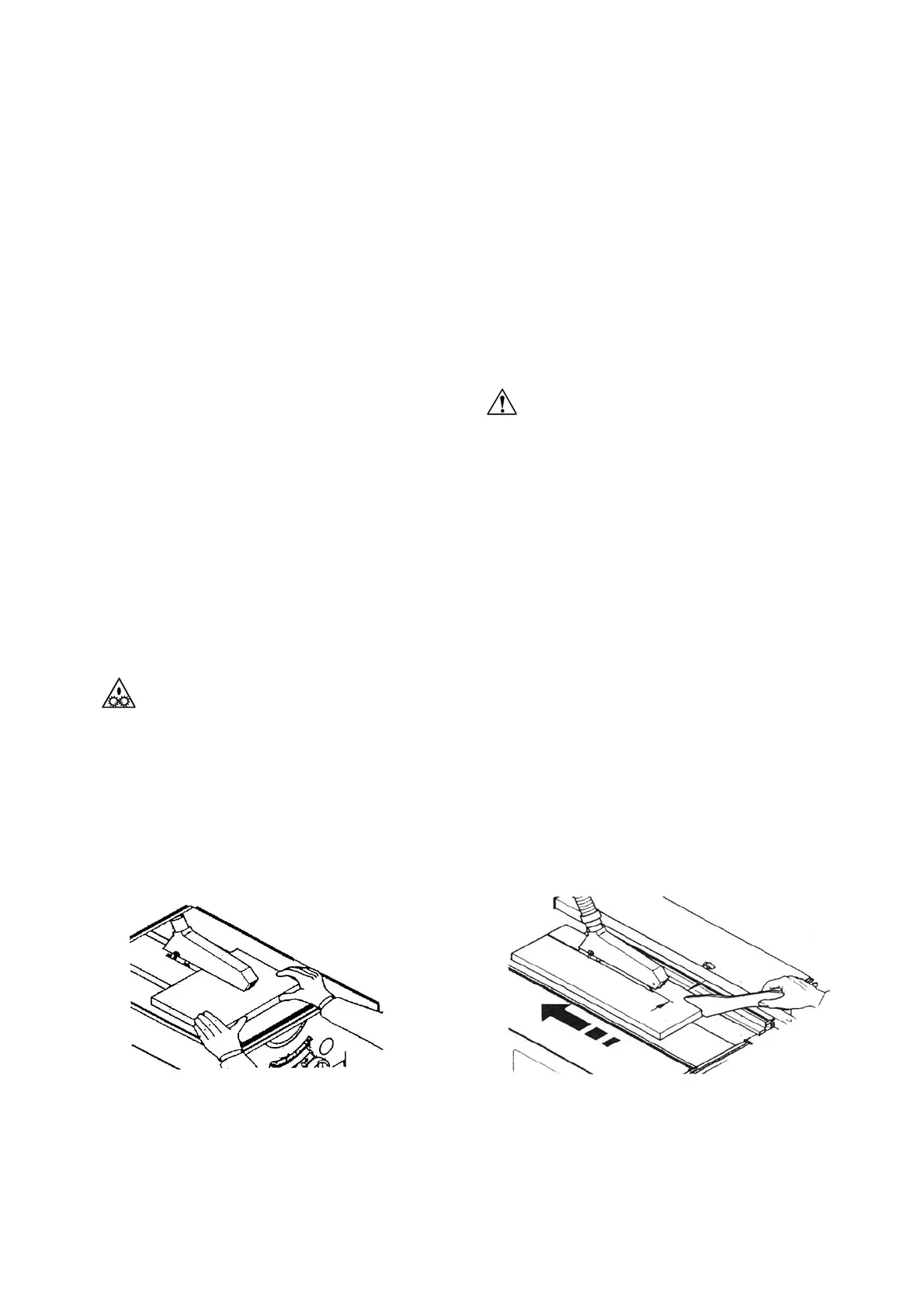

9.3 Rip cuts with rip fence

1. Lock rip fence in required position on saw table.

Danger!

Use push stick if distance between rip fence and saw

blade is less than 120mm.

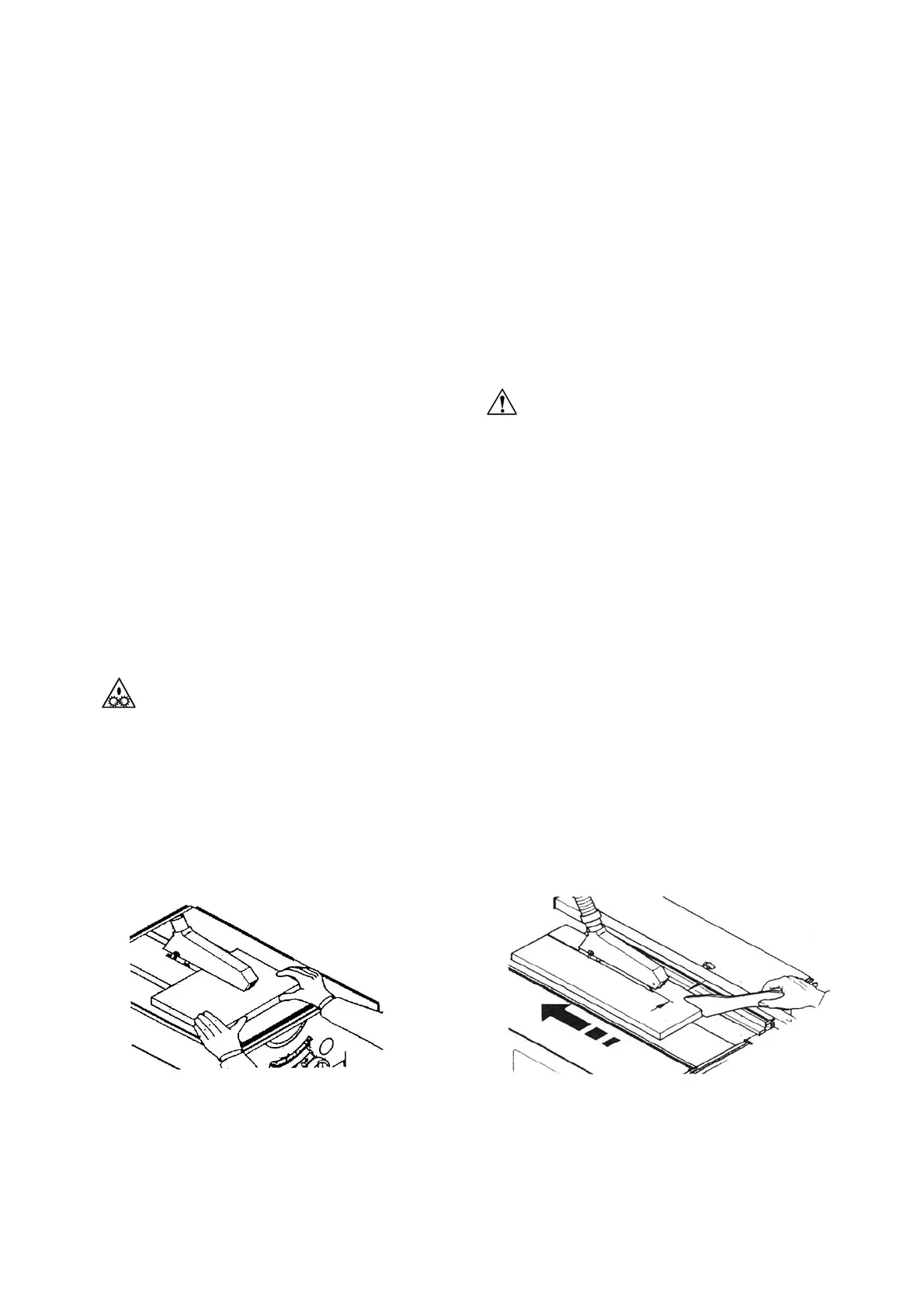

Use of push block and push stick.

Push stick should be used to avoid working with

hands close to the sawblade. Push blocks should be

between 300mm and 400mm long, 80mm to 100mm

wide and 15mm to 20mm deep. Push blocks should

be used when cutting small work-piece and in

circumstance where it is necessary to push the

work-piece against the fence.

The information concerning maintenance and repair

of push sticks, you must change the part by a new

one when you are sure the push stick or push block is

damaged in order to avoid being injured by the

running saw blade.

2. Reposition auxiliary fence extrusion if necessary:

- Low edge (as shown) = for sawing thin stock, and

with a tilted saw blade.

- High edge = for cutting thick stock (max. 65mm).

3. Set blade tilt and lock in position.

4. Start motor.

5. Cut work-piece in a single pass.

6. Switch machine off if no further cutting is to be

immediately afterwards.

Loading...

Loading...