11. Tips and Tricks

z Before cutting a work-piece to size make trial cuts with

pieces of scrap.

z Always place a work-piece on the saw table in such way

that it can not tilt or rock (e.g. always place a curved

board on the table with the convex side up).

z When working long stock use suitable supports, such

as table rear or side extensions (optional accessories).

z Keep surfaces of saw table and saw base clean - in

particular, remove resin residue with a suitable

cleaning and maintenance spray.

12. Repairs

Danger!

Repairs to electric tools must be carried out by

qualified electricians only!

Electric tools in need of repair can be sent to the service

centre of your country.

Refer to the spare parts list for the address.

Please attach a description of the fault to the electric tool.

13. Trouble Shooting

Danger!

Before carrying out any fault service or maintenance

work always:

1. switch machine OFF

2. unplug power cable

3. wait for saw table to come to standstill.

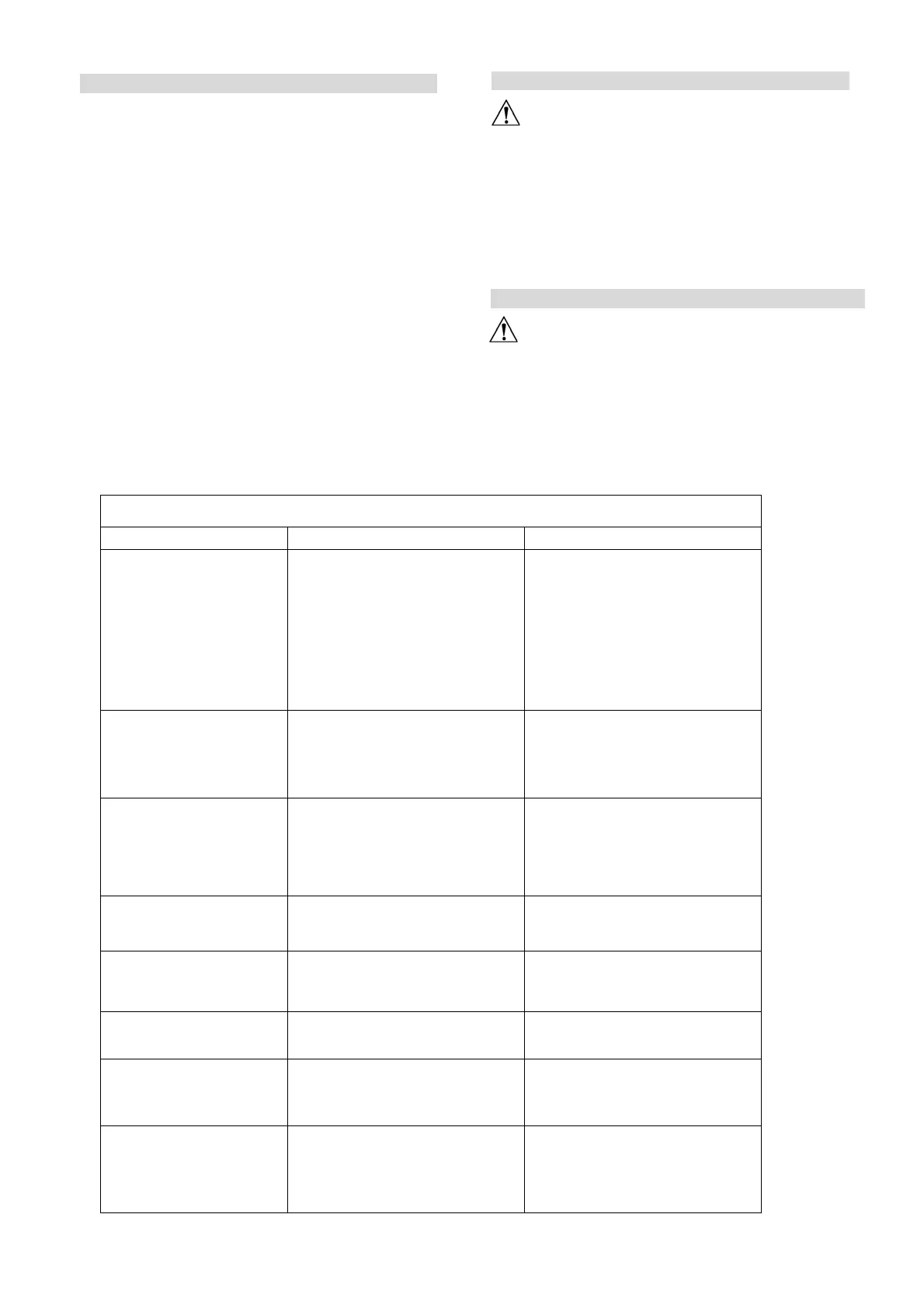

Trouble Shooting Guide, (cont.)

Problem Cause Solution

Motor is slow or weak

Voltage from source is low.

Windings are burned out or open.

Power Switch is defective.

Circuit is overloaded with appliances,

lights, or other electrically powered

equipment.

Request a voltage check from local

power company.

Have the Motor checked / repaired.

Have the Power Switch replaced.

Do not use other appliances or

electrically powered equipment on the

same circuit when using the Table Saw.

Motor overheats. Motor is overloaded.

Dull 10” saw blade.

Sawdust inside table saw is blocking

airflow.

Request a voltage check from the local

power company.

Replace the 10” saw blade.

Clean out the saw base.

When ripping, the cut burns the

work-piece, or stalls the motor.

10” saw blade teeth are dull.

Work-piece is warped.

Rip fence is not parallel with the 10” saw

blade.

Sharpen or replace the 10” saw blade.

Replace the work-piece.

Realign rip fence, and lock it in position

with the Rip Fence Handle.

Miter-gauge does not move

freely.

Miter gauge assembly is dirty.

Loosen the miter gauge knob, clean and

lubricate the Miter Gauge Rod.

Rip Fence does not move

smoothly.

Rip Fence is mounted incorrectly. Remove, reposition Rip Fence, and lock

it in position with the Rip Fence Handle.

Bevel & Height Handles are

hard to turn.

Sawdust has collected on the

mechanisms inside the base.

Clean and lubricate the mechanisms

inside the base.

10” saw blade does not lower

when turning the Height

Handle.

Bevel Lock Handle is not fully released. Fully release the Bevel Lock Handle.

Table saw vibrates excessively. Floor surface is uneven.

V-belt is damaged.

10” saw blade is damaged.

Loose bolt, Screws, Nuts.

Readjust the Leveling Feet.

Replace the V-belt.

Replace the 10” Saw Blade.

Tighten all Hardware.

12

Loading...

Loading...