3EN

READ THIS FIRST

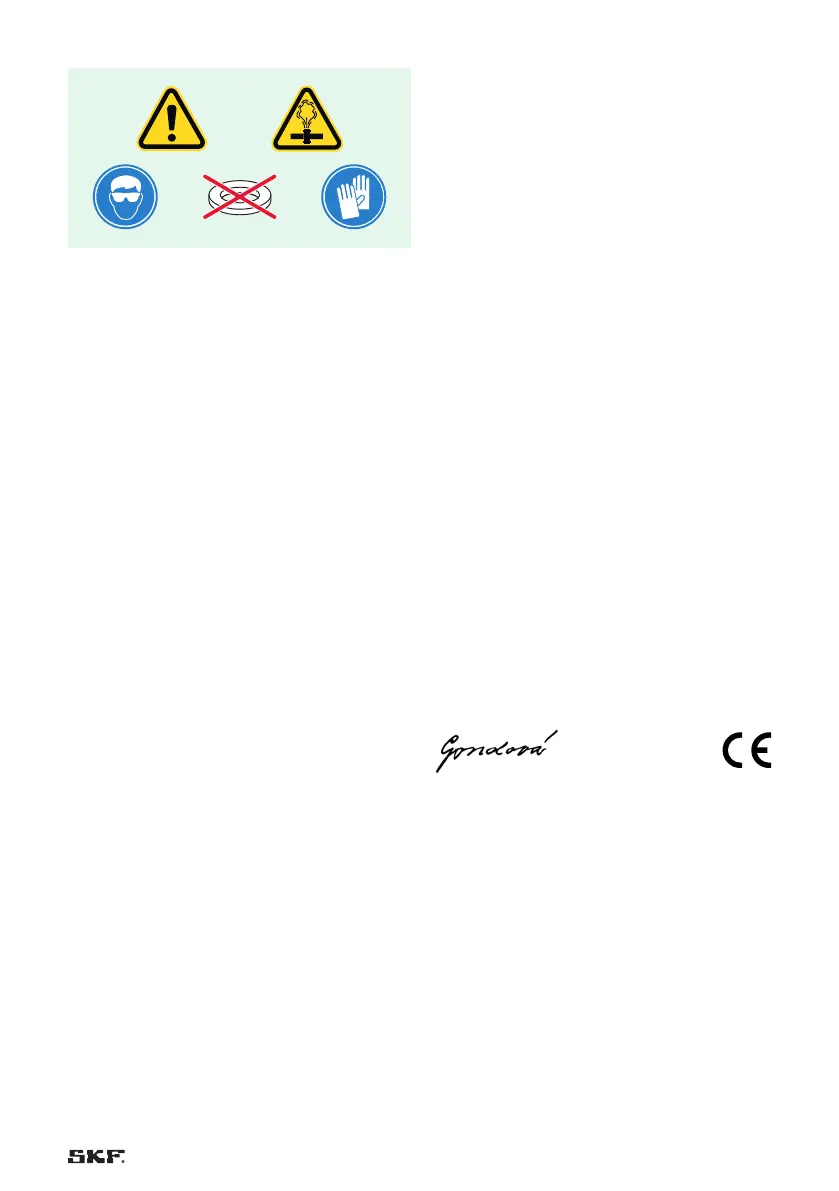

Safety precautions

Read this instruction for use fully. Follow all safety

precautions to avoid personal injury or property

damage during equipment operation. SKF cannot

be responsible for damage or injury resulting from

unsafe product use, lack of maintenance or incorrect

equipment operation. In case of any uncertainties as

regards the use of the equipment contact SKF.

Failure to comply with the following could cause

equipment damage and personal injury.

• Do ensure that the equipment is only operated

by trained personnel.

• Do wear proper personal protective gear, such

as eye protection and protective gloves, when

operating the equipment.

• Do inspect the equipment and all accessories

carefully before use.

• Do ensure that all the air has been removed

from the hydraulic system before pressurising

the hydraulic system.

• Do prevent the workpiece (e.g. bearing,

gearwheel or similar item) from being forcibly

ejected upon sudden release of pressure

(e.g. by use of retaining nut).

• Do use clean recommended hydraulic oils

(SKF LHMF 300, LHDF 900 or similar).

• Do use a pressure gauge to monitor the oil

outlet pressure.

• Do not use damaged components or modify the

equipment.

• Do not use glycerine or water-based fluids as a

pressure medium. Premature equipment wear

or damage can result.

• Do not use the equipment above the stated

maximum hydraulic pressure.

• Do not extend the handle in order to reduce the

required force to reach maximum pressure. Use

hand pressure only.

• Do not use the pump with accessories, which

are rated below the maximum working pressure

of the injector.

• Do not use washers on sealing surfaces.

• Do not handle pressure hoses under pressure.

Oil under pressure can penetrate the skin,

causing serious injury. If oil is injected under the

skin, seek medical attention immediately.

• Do not use damaged pressure hoses.

Avoid sharp bends and kinks when connecting

hoses. Sharp bends and kinks will internally

damage the hose leading to premature failure.

Applying pressure to a damaged hose may

cause it to rupture.

• Do not lift the equipment by the hose or

couplings.

EU Declaration of Conformity

THHP 300

We, SKF MPT, Meidoornkade 14, 3992 AE Houten,

The Netherlands herewith declare under our sole

responsibility that the products described in these

instructions for use, are in accordance with the

conditions of the following Directive(s):

MACHINERY DIRECTIVE 2006/42/EC

and are in conformity with the following standards:

EN-ISO 12100:2010, EN ISO 14121-1,

ISO 4413:2010

Houten, The Netherlands, November 2020

Mrs. Andrea Gondová

Manager Quality and Compliance

Loading...

Loading...