7EN

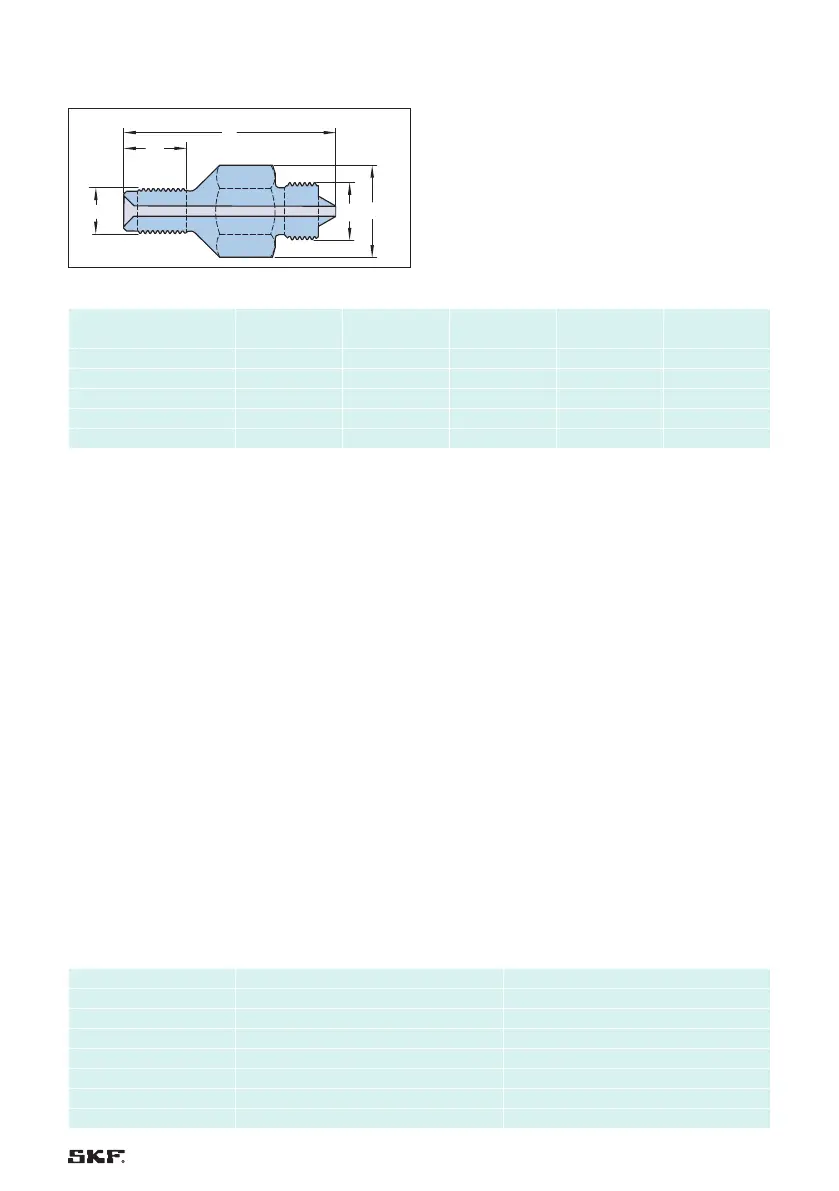

2.6 Application connection nipples

G

1

A

G

2

L

1

L

Fig.3 – Dimensions of the THPN M16 nipples

Item A

mm

G1 G2 L

mm/in

L1

mm/in

THPN M16G1/8 Hex 22 G1/8 M16x1.5 60/2.36 15/0.59

THPN M16G1/4 Hex 22 G1/4 M16x1.5 60/2.36 17/0.67

THPN M16G3/8 Hex 22 G3/8 M16x1.5 60/2.36 20/0.79

THPN M16G1/2 Hex 22 G1/2 M16x1.5 60/2.36 20/0.79

THPN M16G3/4 Hex 32 G3/4 M16x1.5 67/2.64 30/1.81

2.7 Hydraulic oil

The pump is filled with SKF Mounting Fluid

LHMF 300.

Dirt and metal particles in the oil can cause wear of

the piston mating surfaces, leading to excessive oil

leakage and permanent damage to the THHP 300.

The recommended oil cleanliness level should meet

or exceed ISO 4406:1999 20/18/15.

Using fluids or oils, other than SKF mounting and

dismounting fluids, can cause corrosion and/or

damage to mating surfaces.

Do not mix fluids or oils of different brands.

Use appropriate oil with a viscosity of 300 cSt, at

operating temperature, to mount bearings and

similar items using the SKF Oil Injection Method.

SKF hydraulic fluids used in our pumps are

especially formulated for the mounting and

dismounting processes. In the table below is an

overview of what to use when:

Job type Environment temperatures SKF Oil

Mounting 0 °C (32 °F) to 35 °C (95 °F) SKF Mounting Fluid, LHMF 300

35 °C (95 °F) to 45 °C (113 °F) SKF Dismounting Fluid, LHDF 900

Dismounting 0 °C (32 °F) to 10 °C (50 °F) SKF Mounting Fluid, LHMF 300

10°C (50 °F) to 45 °C (113 °F) SKF Dismounting Fluid, LHDF 900

Loading...

Loading...