Page 24

ERGON SERVICE • REV0

5-6. AFS Flatscreen Arm Series Adjustments

During any maintenance or adjustment procedure,

checkallattachinghardwareforpropertightness.

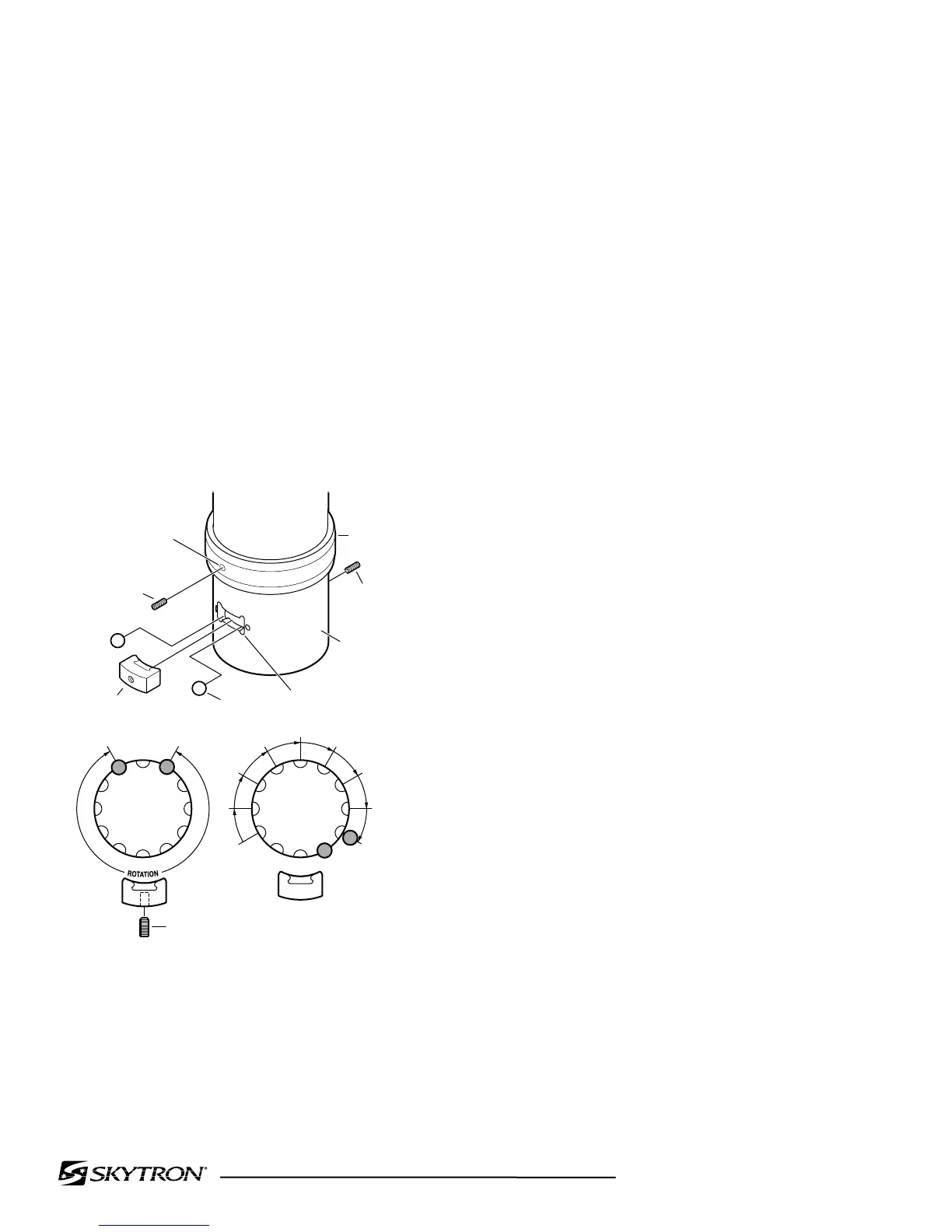

a. Flatsceen Arm Bearing Stop Assembly

CAUTION

It is necessary to support the arm

assembly prior to removal of any

hardware. Failure to do so will result

in the inadvertent release of the arm.

1. Remove set screws securing Stop

Collar.Refertogure5-18.

Figure 5-18.

2. Remove Stop Key and Stop Balls (2).

3. Determine new Stop Ball placement.

4. Installstopballsandstopkey.Alignthe

stop collar so the through hole lines up with the set

screwholeinthestopkeyandinstallthesetscrew.

NOTICE

DO NOT overtighten the set screw, it is

usedtoadjustthefrictionbraketension.

5. Tighten the set screw to set the friction

brake. The atscreen arm should move easily

throughitsrangeofrotationwithoutbindingand

hold its position when released.

STOP

COLLAR

OUTER

BEARING

HOUSING

SET

SCREW

KEYWAY

THROUGH

HOLE

SET SCREW

(FASTENS

INTO STOP

KEY)

SET

SCREW

BALL

STOPS (2)

STOP KEY

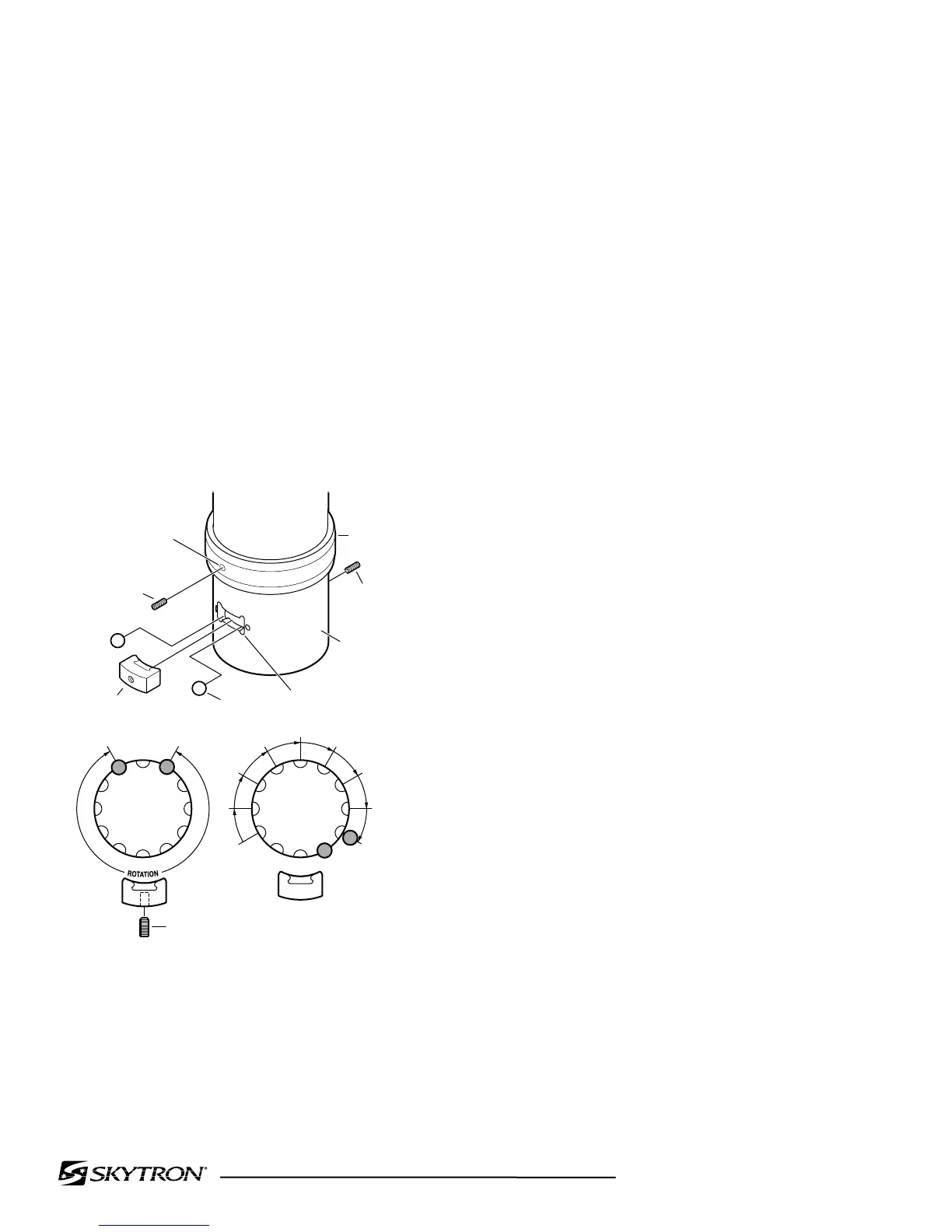

DEGREE OF ROTATION

15° TO 255°

IN 15° INCREMENTS

15

45

75

105

135

165

195

225

255

ROTATION POSITION

*

*

ONE BALL ALLOWS 270° ROTATION

Loading...

Loading...