Page 15

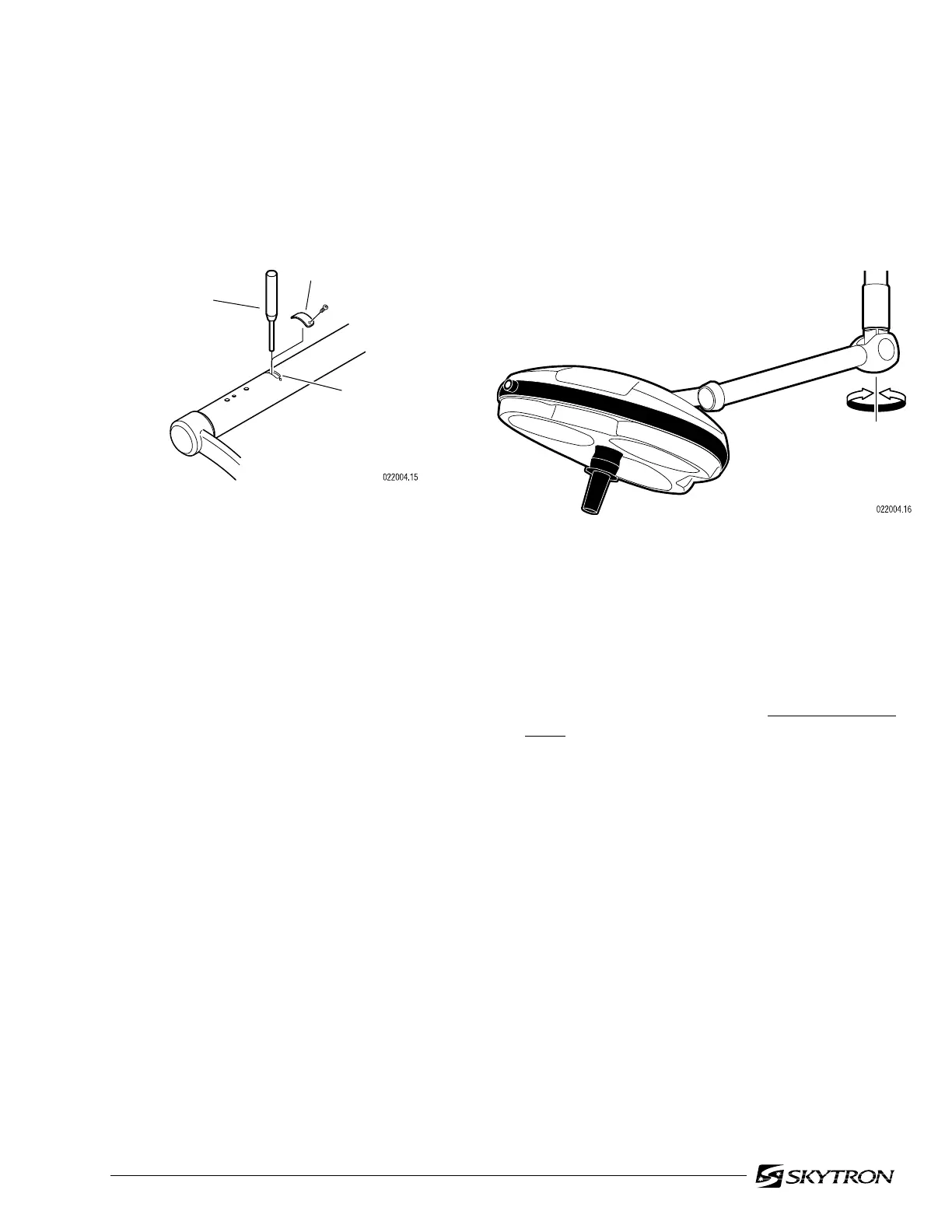

4-5. Lighthead Horizontal Rotation

Adjustment

a. Check horizontal rotation axis adjustment by

moving the lighthead through its full range of travel

around the Balance Mechanism. See figure 4-9.

HORIZONTA

ROTATION

ADJUSTMENT

SLOT

COVER

PLATE

PIN

PUNCH

Figure 4-9. Horizontal Rotation

b. The lighthead should maintain its position

without drifting, yet move freely around the Balance

Mechanism. Normally this adjustment is correct

from the factory and does not change. If the lighthead

drifts, the most likely cause is an unlevel mounting

plate.

b. The lighthead should move freely yet main-

tain its selected position within the range of motion

without drifting. If an adjustment is necessary,

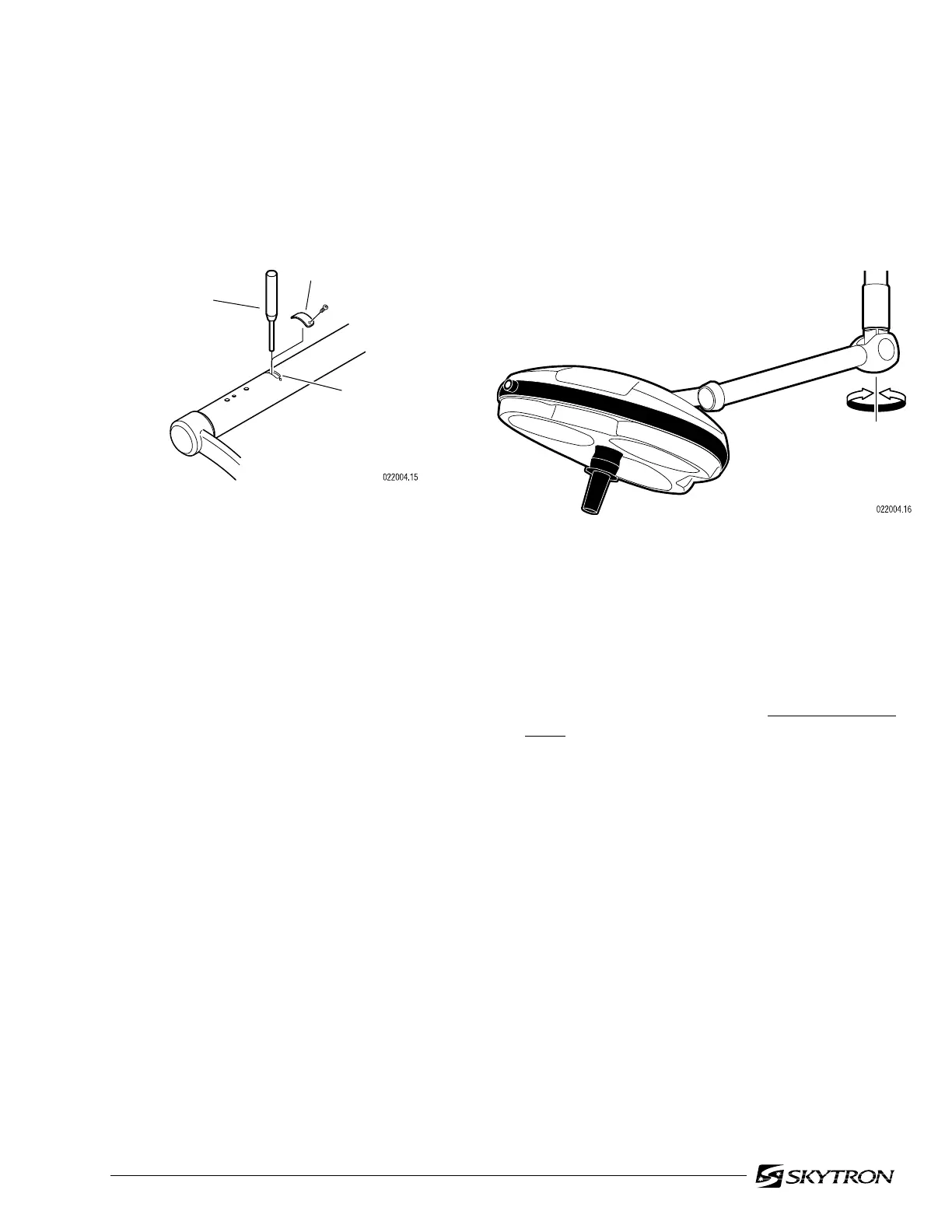

refer to figure 4-8, and proceed as follows:

Figure 4-8. Vertical Travel Adjustment

c. Remove two screws securing the cover

plate and remove the cover plate from the Horizon-

tal Support Arm.

d. Pull the lighthead downward until the adjust-

ment nut is visible through the adjustment slot in the

support arm.

e. Insert a pin punch through the adjustment

slot and into a hole of the spring tension adjustment

nut. Using the pin punch, turn the adjustment nut

clockwise to increase the tension, counterclock-

wise to decrease the tension.

f. Remove the pin punch, check and repeat

adjustment procedure as necessary to achieve

proper spring tension. The lighthead should be able

to hold its position at any angle from the VST.

g. Reinstall cover plate on the Horizontal

Support Arm.

Loading...

Loading...