8

Deleting Stored Torque and Angle Data

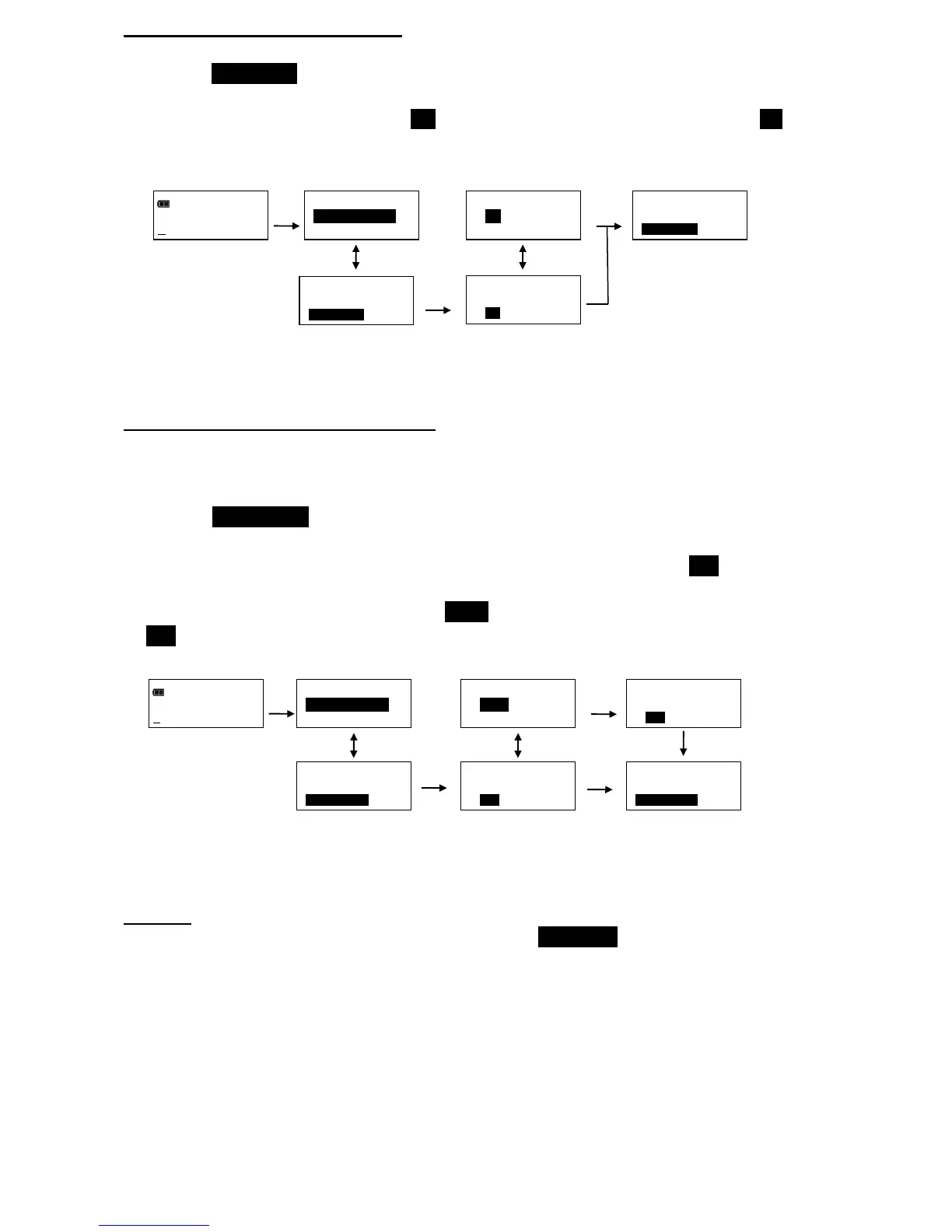

1. From target torque or angle screen, press and hold ENTER button for 3 seconds.

2. Highlight CLEAR DATA menu selection using UP/DOWN buttons then press ENTER button to display

CLEAR ALL DATA screen.

3. In CLEAR ALL DATA screen, highlight YES menu selection to delete all stored data, or NO menu

selection to exit without deleting data.

4. Press ENTER button after making selection.

Note: If wrench is Locked (see Preset Lock in Advanced section), Clear Data function is disabled.

Viewing and Clearing Wrench Cycle Counter

Each time torque or angle target is reached, wrench cycle counter is incremented. Maximum cycle

count is 999999.

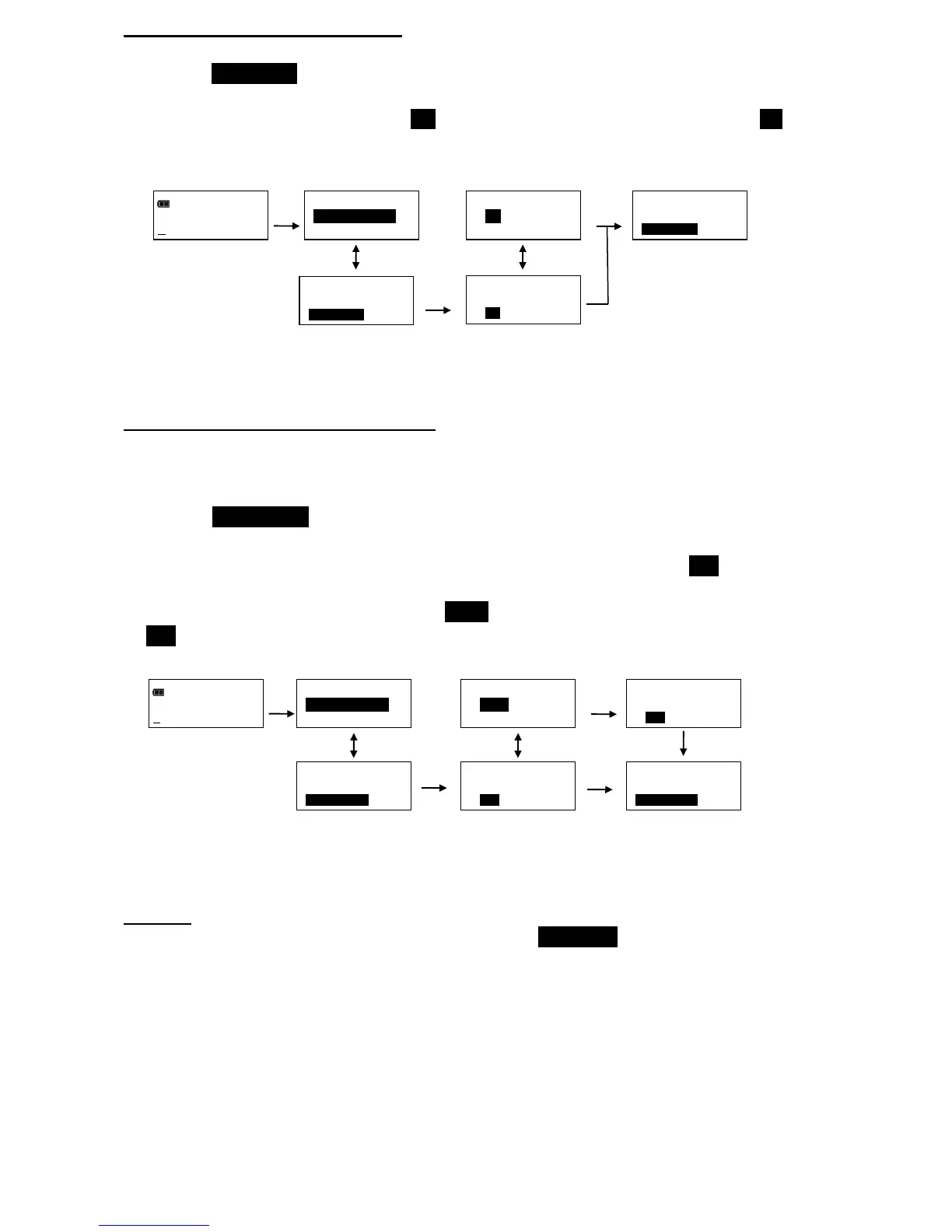

1. From target torque or angle screen, press and hold ENTER button for 3 seconds.

2. Highlight CYCLE COUNT menu selection using UP/DOWN buttons.

3. Press ENTER button to display CYCLE COUNT screen.

4. To exit CYCLE COUNT screen without clearing count, press ENTER button while EXIT menu selection

is highlighted.

5. To reset wrench cycle count to 0, highlight CLEAR menu selection then press ENTER button.

6. EXIT menu selection is automatically highlighted after count is cleared. Press ENTER button to

return to main menu.

Note: If wrench is Locked (see Preset Lock in Advanced section) Clear count function is disabled.

Language

1. To select language menu, press ENTER button while LANGUAGE is highlighted then highlight

desired language and press ENTER button.

2. Decimal Mark selection menu is displayed. Decimal separator can be a comma or decimal point.

Use UP/DOWN buttons to select decimal separator then press the ENTER button.

Note: Decimal separator will affect formatting of downloaded data when opened by Excel depending

on Windows® regional settings.

Loading...

Loading...