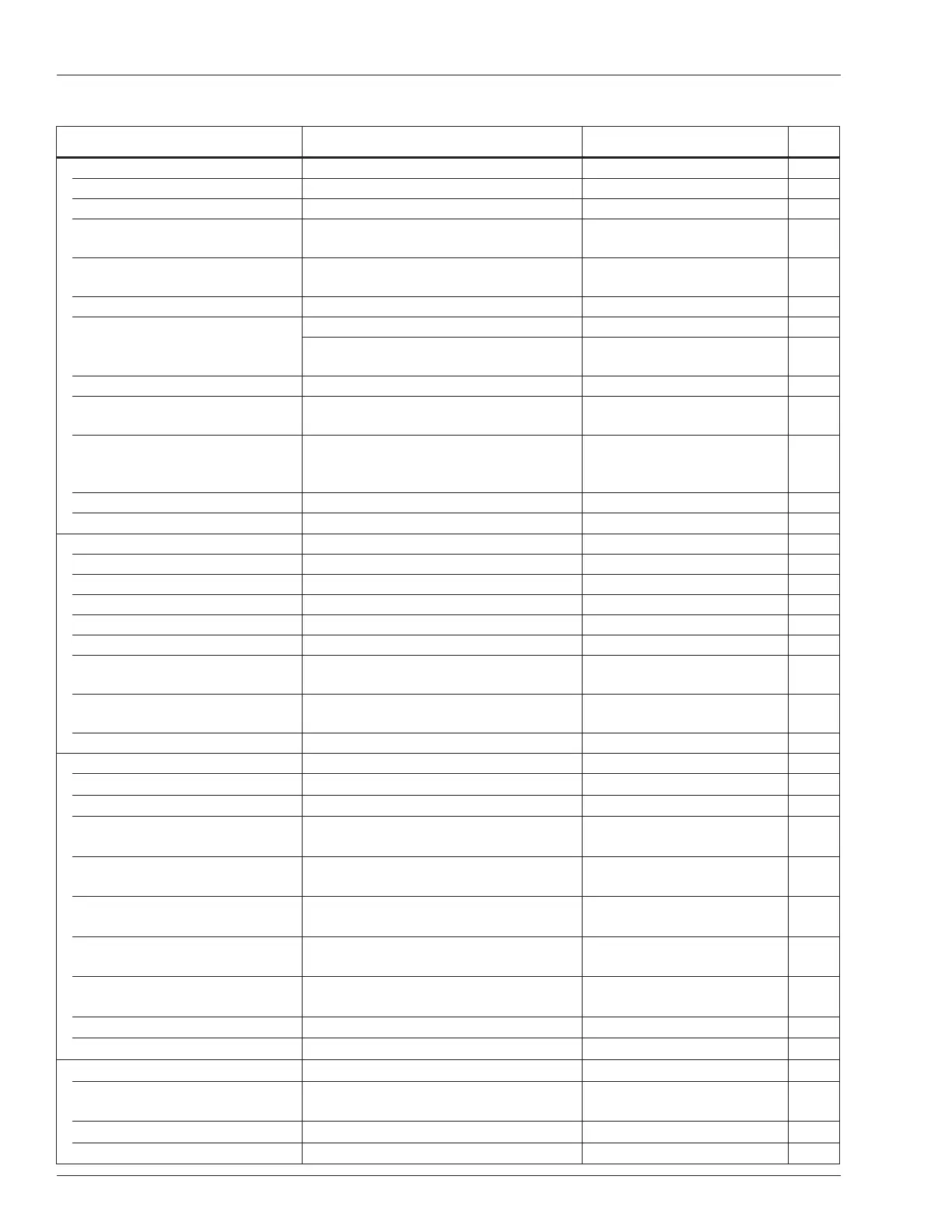

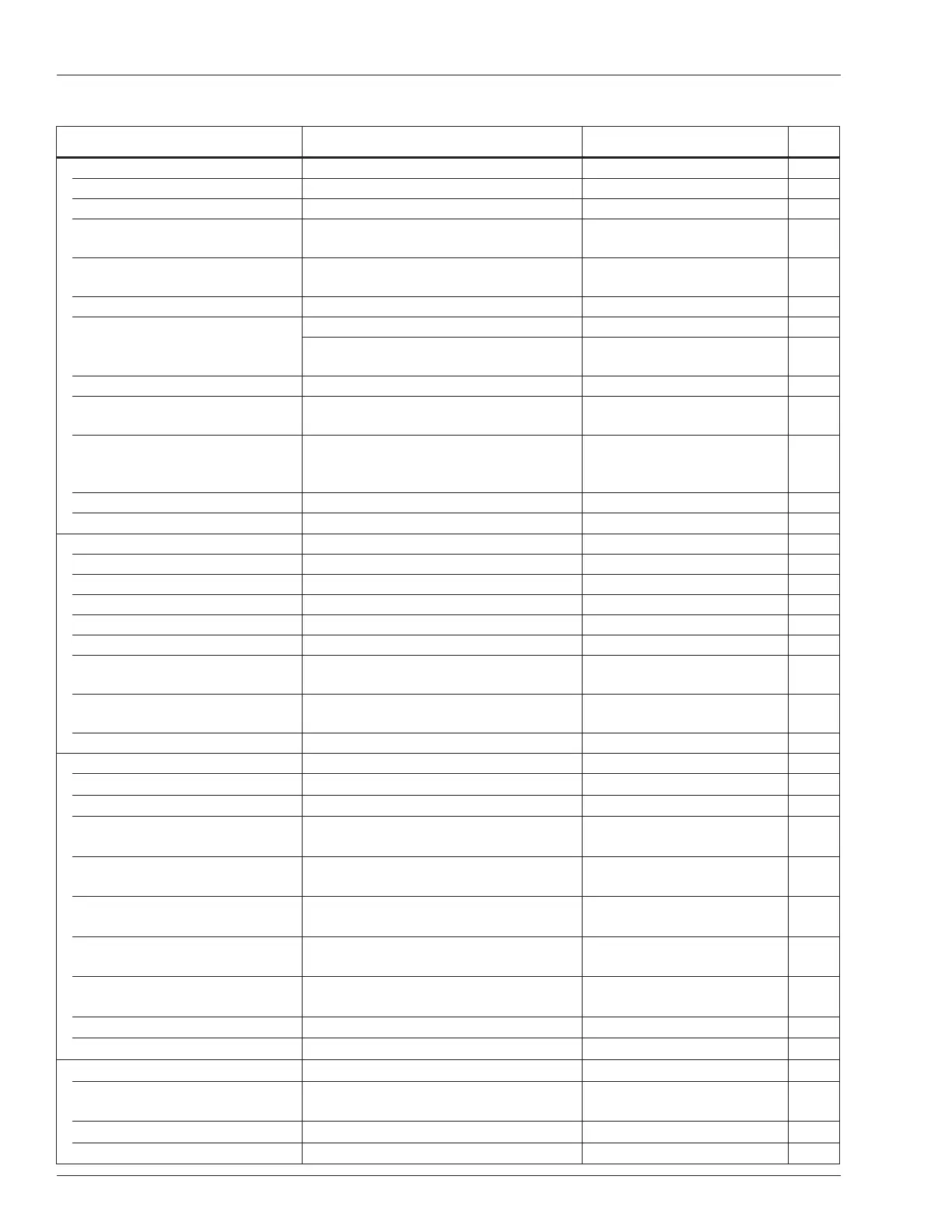

Appendix C – Inspection Checklists

A46JRT – 0260996

Frequent Inspection and Maintenance – Every 90 Days or 150 Hours

Item Procedure Information P/F/R

Chassis

Structural Check for damage and cracked welds

Pins Check for wear and damage

Steering cylinder pin caps and

retaining bolts

Verify that all fasteners are in place

Oscillating axle lock cylinders,

rollpin, and lynch pin

Verify that all fasteners are in place

Steering linkage Check for proper operation

Tires Check for wear and damage

Proper ination 70 psi to 75 psi

Air lled tires only

Hydraulic tubes and hoses Check for leaks, wear, and damage

Decals and placards Check for damage and readability

Order replacements as necessary

Torque drive and steer wheel

lug nuts per placard on wheel

Torque lug bolts/nuts to proper value

on machine placard

4x4 front: 200 to 225 ft lb

4x2 front: 70 to 80 ft lb

All rear: 200 to 225 ft lb

Right drive motor(s) Check for leaks

Left drive motor(s) Check for leaks

Turntable

Structural Check for damage and cracked welds

Pins Check for wear and damage

Torque turntable top bolts Torque to proper value 190 ft lbs

Torque turntable bottom bolts Torque to proper value 190 ft lbs

Hydraulic tubes and hoses Check for leaks, wear, and damage

Cowling Check for wear/damage and that

fasteners are in place and are tight

Wire harness Check for wear/damage and that

fasteners are in place and are tight

Tilt alarm Check for proper operation

Lower Booms

Structural Check for damage and cracked welds

Pins Check for wear and damage

Boom lift cylinder retaining bolts Verify that all fasteners are in place

and are tight

Boom lift cylinder and holding

valve

Check for leaks, wear, damage, and

for proper operation

Riser lift cylinder forged pin

retainer/retaining bolt

Verify that all fasteners are in place

and are tight

Riser lift cylinder and holding

valve

Check for leaks, wear, damage, and

for proper operation

Master level cylinder forged pin

retainer

Verify that all fasteners are in place

and are tight

Hydraulic tubes and hoses Check for leaks, wear, and damage

Electrical Wires Check for wear and damage

Left Hand Access Door

Boom control valve Check for leaks, wear, damage, and

for proper operation

Boom circuit system pressure Check maximum system pressure 2,700 to 2,800 psi

Filter minder gauge Check for proper operation

Loading...

Loading...