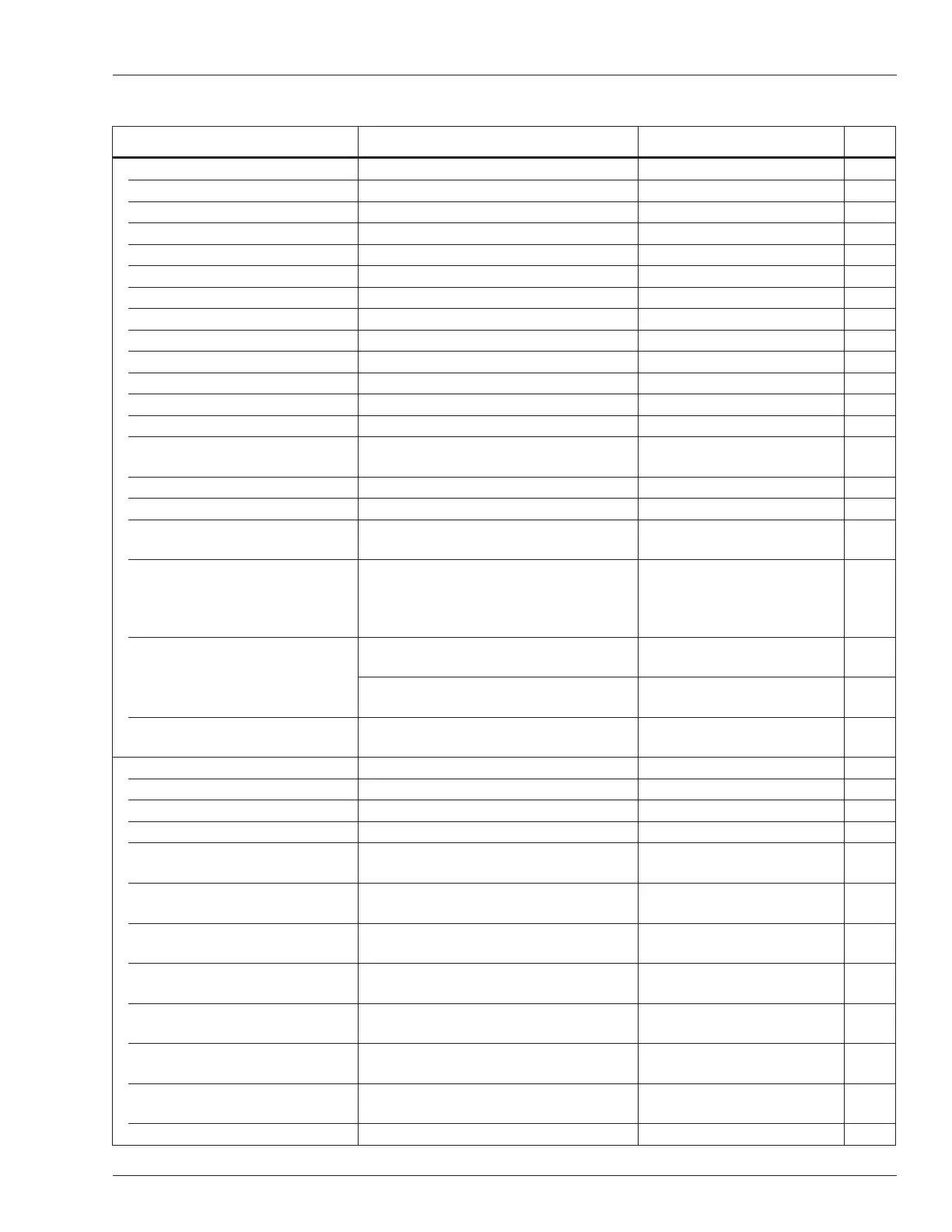

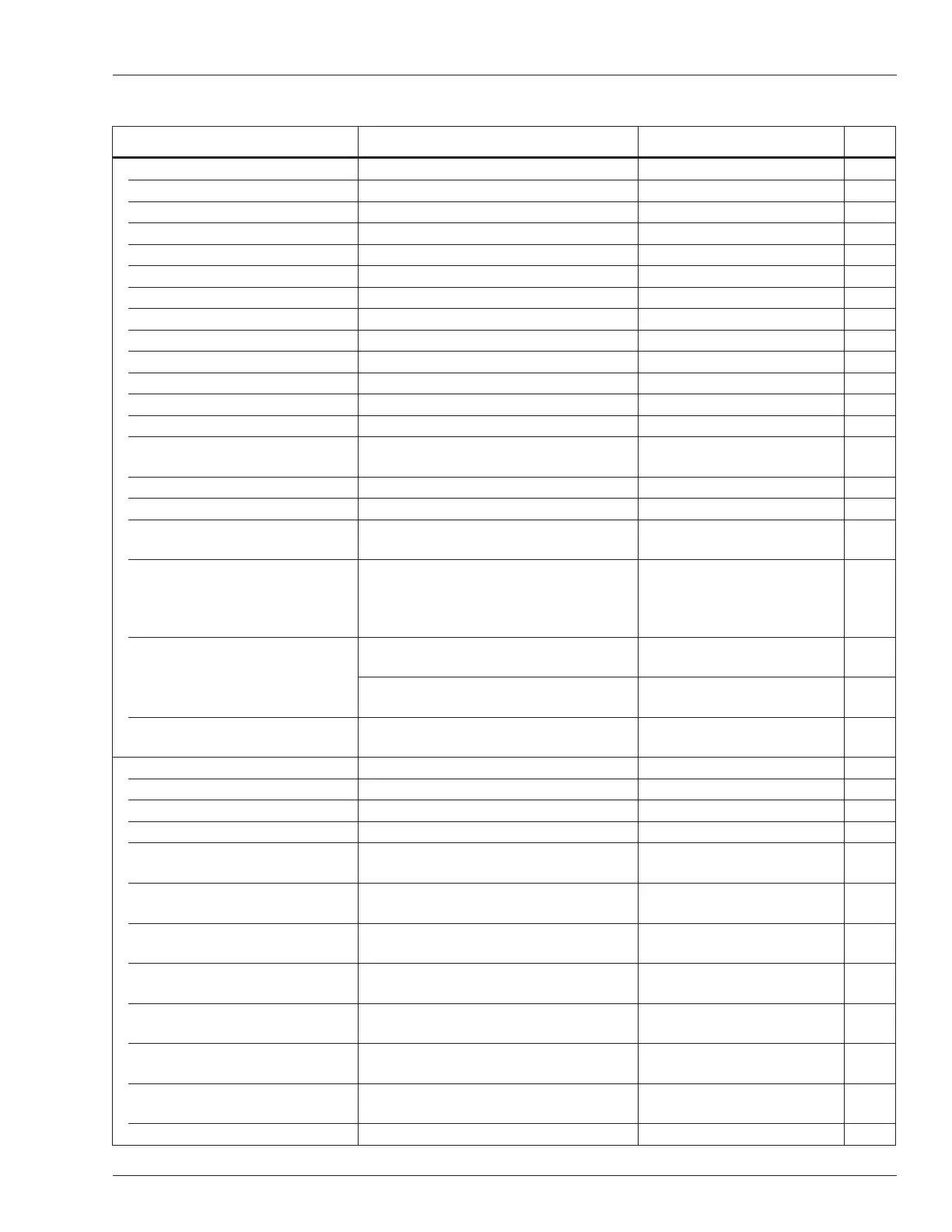

Appendix C – Inspection Checklists

A46JRT – 0260996

Frequent Inspection and Maintenance – Every 90 Days or 150 Hours

Item Procedure Information P/F/R

Engine Compartment

Structural Check for damage and cracked welds

Fuel tank Check for leaks, wear, and damage

Fuel gauge Check for proper operation

Fuel tank cap Check for leaks, wear, and damage

Engine air lter Check for wear and damage

Engine belts and hoses Check for wear and damage

Engine oil Check for wear and damage/level

Between add and full marks

Engine coolant level Check for level Between hot and cold level

Engine Check for proper operation

Engine start – stop Check for proper operation

Electric throttle Check for proper operation

Engine charging system Check for proper operation

Engine shutdown, low oil

pressure

Check for proper operation

Hydraulic pump Check for proper operation

Hydraulic oil reservoir Check for wear/damage/leaks

Hydraulic oil reservoir ller/

breather cap

Verify that all fasteners are in place

and are tight

Hydraulic oil reservoir uid level Check for proper level Above 10°F (-12°C)

ISO VG32

Below 10°F (-12°C)

ISO VG15

Hydraulic oil return lter Replace after the rst 50 hours, every

90 days or 150 hours thereafter

Inspect lter for foreign matter that

could indicate component wear

Drive system control valve Verify that all fasteners are in place

and are tight

Upper Booms

Structural Check for damage and cracked welds

Pins Check for wear and damage

Electrical wires Check for wear and damage

Extension cylinder pins, snap

rings, and forged pin retainers

Verify that all fasteners are in place

and are tight

Extension cylinder and holding

valve

Check for leaks, wear, damage, and

for proper operation

Jib cylinder pin and retainer bolt Verify that all fasteners are in place

and are tight

Jib cylinder and holding valve Check for leaks, wear, damage, and

for proper operation

Slave level cylinder pin caps

and retainer bolt

Verify that all fasteners are in place

and are tight. Torque to proper values.

25 ft lb

Slave level cylinder holding

valves

Check for leaks, wear, damage, and

for proper operation

Hose carrier assembly Check for residue buildup/proper

operation

Hydraulic hoses and tubes Check for leaks, wear, and damage

Loading...

Loading...