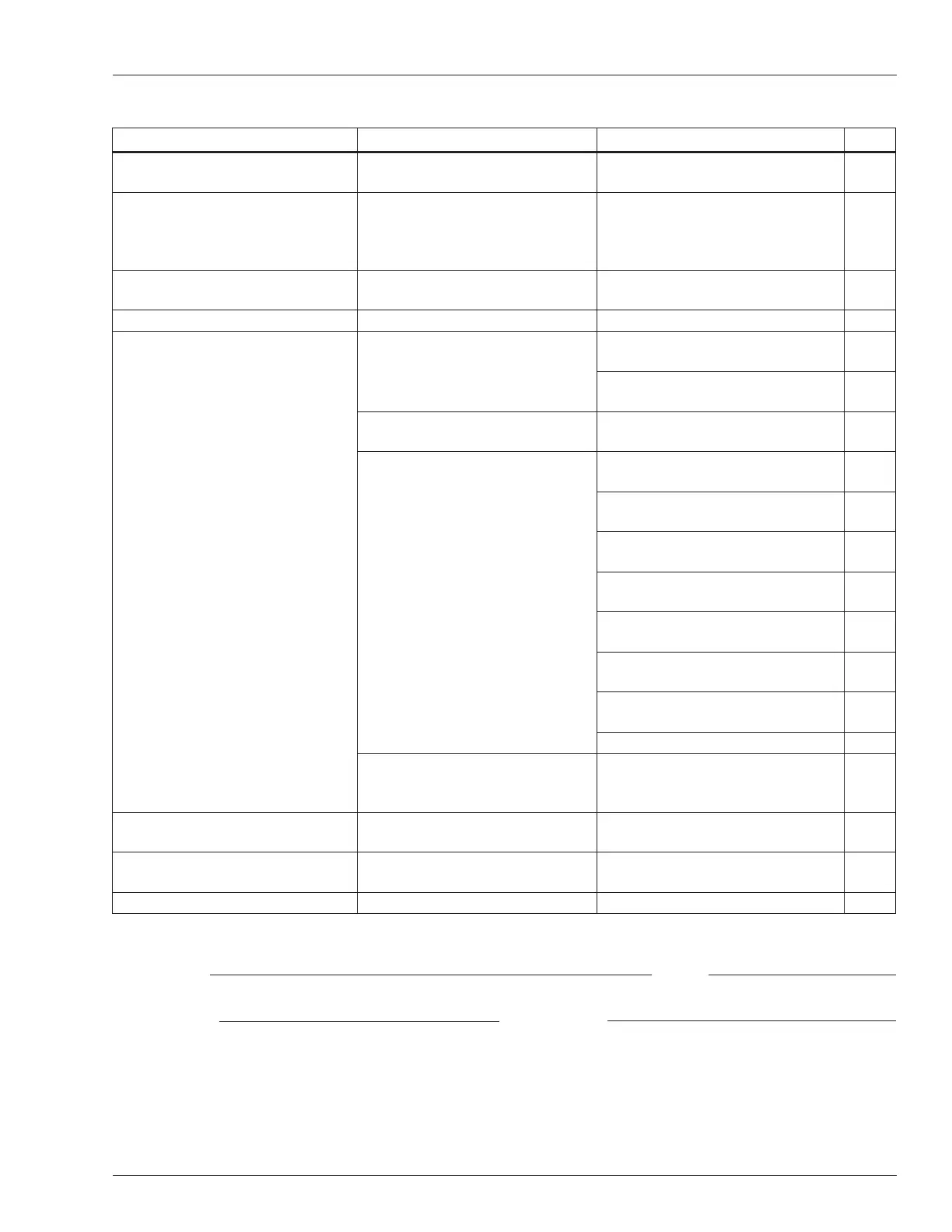

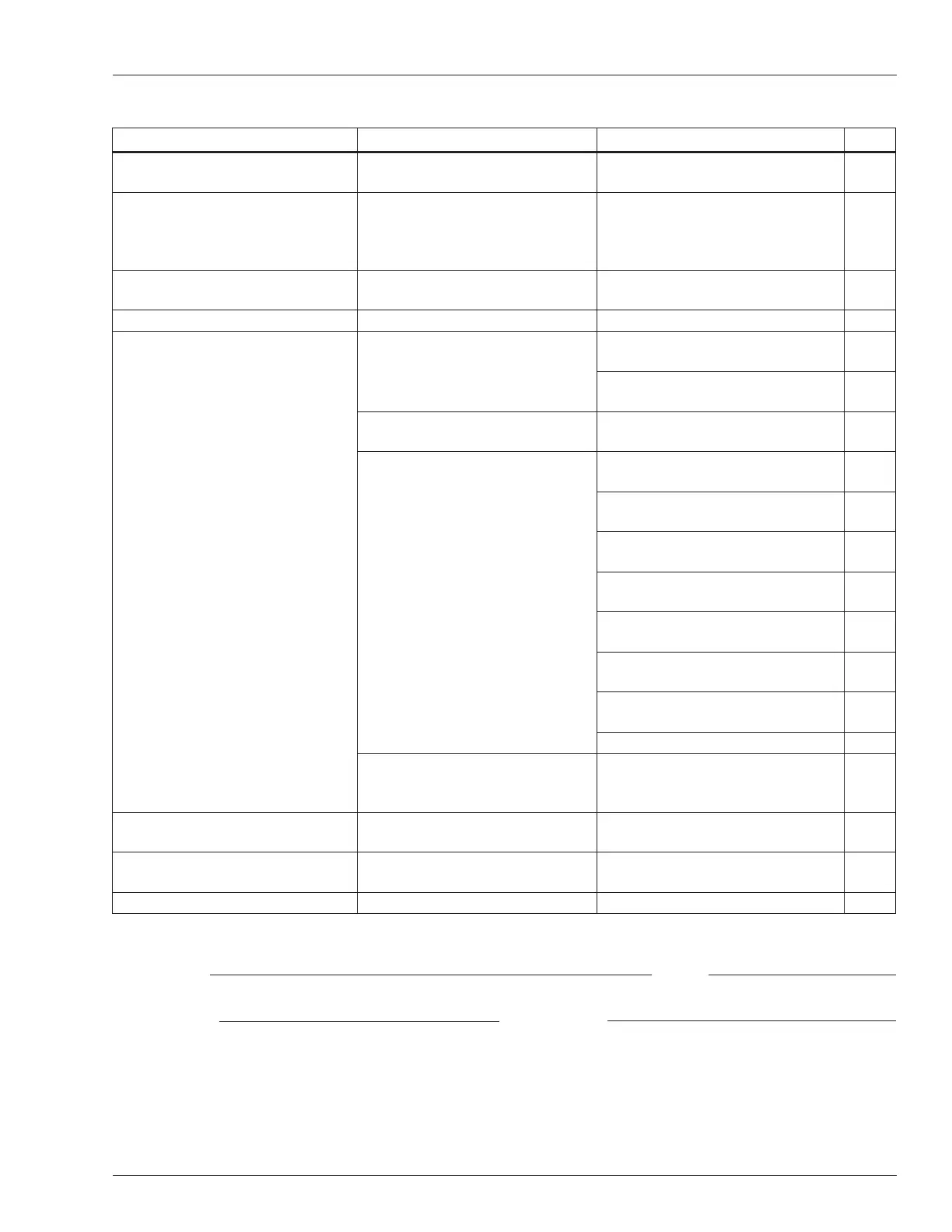

Appendix C – Inspection Checklists

A46JRT – 0260996

Annual Maintenance – Every 500 Hours

Item Procedure Information P/F/R

90 day or 150 hour maintenance Perform maintenance per

schedule

Retain copy of checklist

Hydraulic oil reservoir Clean and replace uid Above 10°F (-12°C)

ISO VG32

Below 10°F (-12°C)

ISO VG15

Hydraulic return lter Replace After rst 50 hours, then at

recommended interval

Hydraulic reservoir suction lter Clean and reinstall

Hydraulic pressures Drive pump setting Dierential pressure:

450-500 psi

Maximum pressure:

5,000-5,100 psi

Boom pump setting Maximum pressure:

2,750-2,800 psi

Function pressures: check at

manifold, except level

Steer right/left:

2,700-2,800 psi

Riser boom down:

3,300-3,400 psi

Main boom down:

1,400-1,500 psi

Extend:

1,900-2,000 psi

Jib up/down:

2,700-2,800 psi

Rotate:

1,200 psi max on level

Pressure reducing valve:

2,700-2,800 psi

Drive/boom relief: 3,000 psi

Level Pressure: install gauge

between valve and slave

cylinder

Level:

2,000-2,050 psi

Gear hubs Replace uid Gear lubricant

SAE Grade 80W-90

Swing drive Replace uid Gear lubricant

SAE Grade 80W-90

Engine coolant Check condition See engines owner’s manual

Performed by: Date:

Model Number: Serial Number:

Maintenance Table Key: P = Pass, F = Fail, R = Repaired

Loading...

Loading...