Start & Stop Parameters

19

Maximum Start Time

The maximum allowable starts time, from start signal

to end of acceleration. If voltage does not reach full

voltage during this time (for example, because of low

Current Limit setting), the starter will trip the motor.

LCD displays “Long Start Time” message.

Range: 1-30 sec (consult factory for extended range).

Contact Delay

Time delay for End of Acceleration Contact, after

completion of starting process. Range: 0-120 sec.

Pump Control – Stop curve

Intended to prevent Water Hammer during stopping. In

pump applications, load torque decreases in square

relation to the speed, thus, reducing the voltage will

reduce torque and motor will smoothly decelerate to a

stop.

The following Stop curves can be selected:

Stop curves 0 – Standard Default curve – voltage is

linearly reduced from nominal to zero.

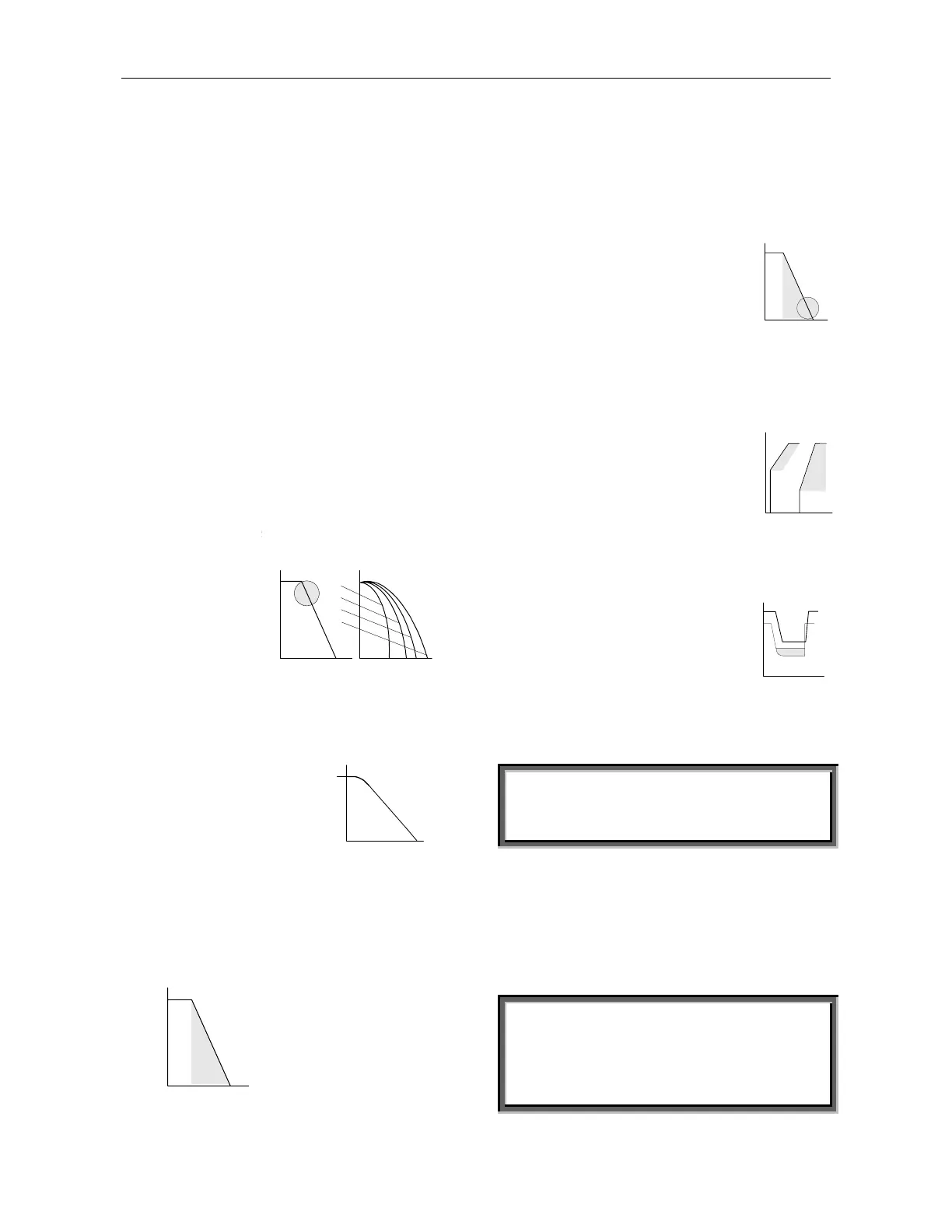

Stop curves 1, 2, 3 –

In some pump

applications, when

pumping to a higher

level, a considerable

part of the torque is

constant and does

not decrease with

speed. It may happen

that during Soft Stop, when voltage is decreasing,

motor torque quickly falls below load torque and motor

will abruptly stall instead of smoothly decreasing speed

to zero.

Stop Curve 4 (Torque) –

Provides Linear Controlled

torque deceleration ramp,

from Ta (Actual Torque),

thus, eliminating stall

conditions.

Note:

Always use Stop Curve 0. If motor stalls

quickly instead of slowly decreasing its speed,

select Stop Curve 1, 2, 3 or 4 if necessary.

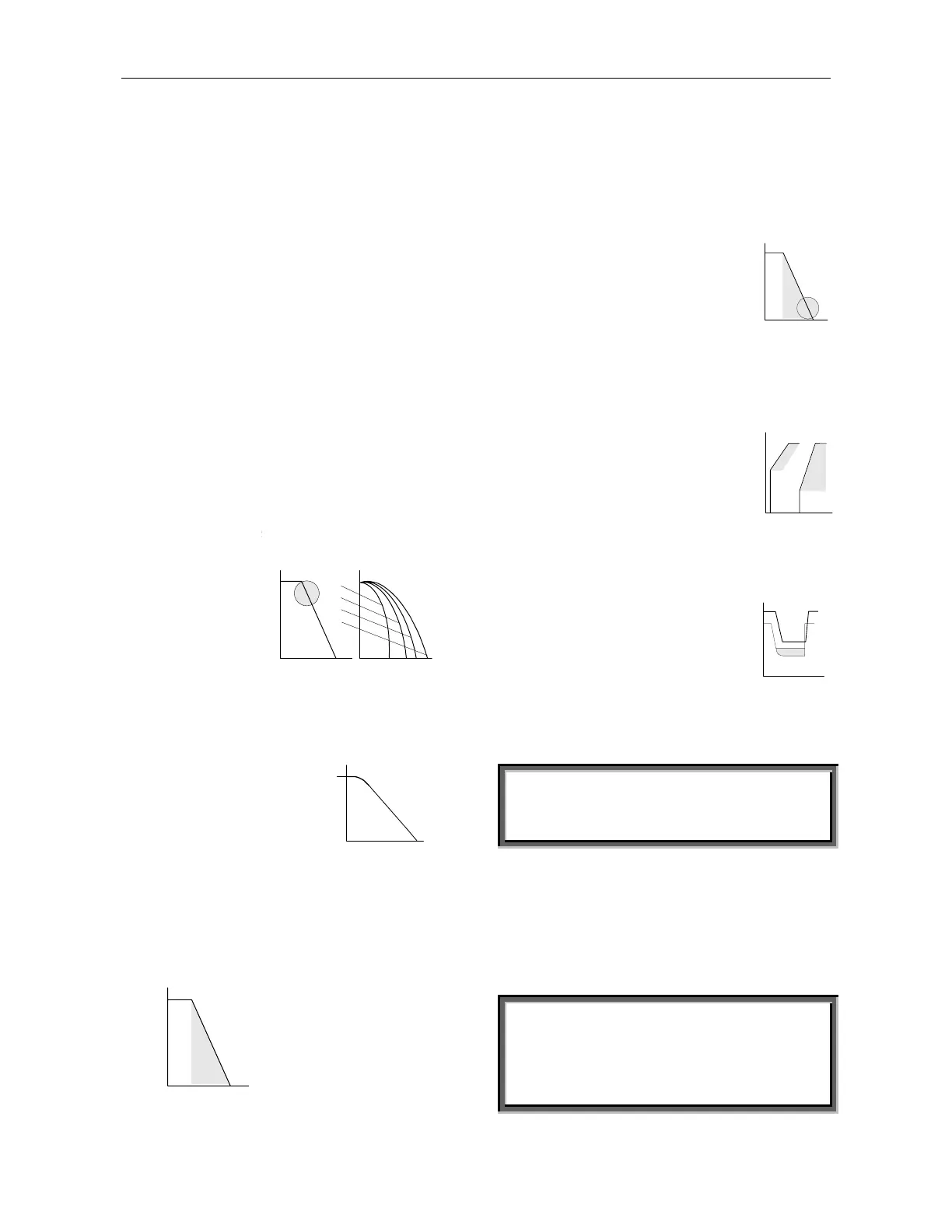

Deceleration Time – Soft Stop

U%

2

100%

30sec

Used for controlled

deceleration of high friction

loads. Determines motor’s

voltage ramp down time.

Range: 1-30 sec. (consult

factory for extended range).

Note: When the starter operates with a by-pass

contactor, Soft Stop initiation opens the End Of

Acceleration contact, tripping open the by-pass

contactor. Load will then be transferred to the RVS-

DN and voltage begins ramping down.

Final Torque

Determines torque towards end of

Soft Stop. If current is still flowing

after speed is softly reduced to zero,

increase Final Torque setting.

U%

2

100%

30 sec

Dual Adjustment

A secondary set of parameters, used for varying loads,

two speed motors, etc. Connecting Control Supply to

Terminal 8 makes transfer to Dual Adjustment settings.

IV - Initial Voltage 10-50% of Un.

CL - Current Limit 100-400%

of motor’s FLA

AT - Acceleration Time 1-30 sec.

DT - Deceleration Time 1-30 sec.

FLA- Motor Full Load Ampere.

U%

100%

sec

2- -302- -10

40%

100%

20%

Note: Consult factory for extended range.

Energy Save

Activated when motor is lightly

loaded for extended periods of time.

Supply voltage the motor decreases

(lowering the rotating magnetic

field intensity), thus, reducing the

reactive current and copper/iron

losses.

U Starter

In

Un

0.5

I Motor

Note: When using Energy Save system, harmonics

should be taken into consideration. At maximum

Energy Save settings, the 5

th

harmonic may exceed

30% of the RMS current value.

ATTENTION

To meet CE standards while in Energy Save mode,

the user may be required to employ additional

mitigation methods.

Slow Speed Torque

Determines the torque while motor is operating at 1/6

of nominal speed. Range: 1-10.

Maximum Slow Speed Time

Determines the maximum allowable operation time at

slow speed. Range: 1-30 sec. (consult factory for

extended range).

WARNING

Operating current while motor is running at 1/6 speed

is much higher than nominal current and motor

ventilation is much weaker. Special precaution must

be taken to prevent overheating when running the

motor at slow speed for long periods of time.

urves 1, 2, 3 designed to prevent

tall condition

Voltage Deceleration

1!!

0

2!!

3!!

t

Torque

Ta

Time > t1

Increased time

smoothes the Peak

Loading...

Loading...