Start & Stop Parameters

18

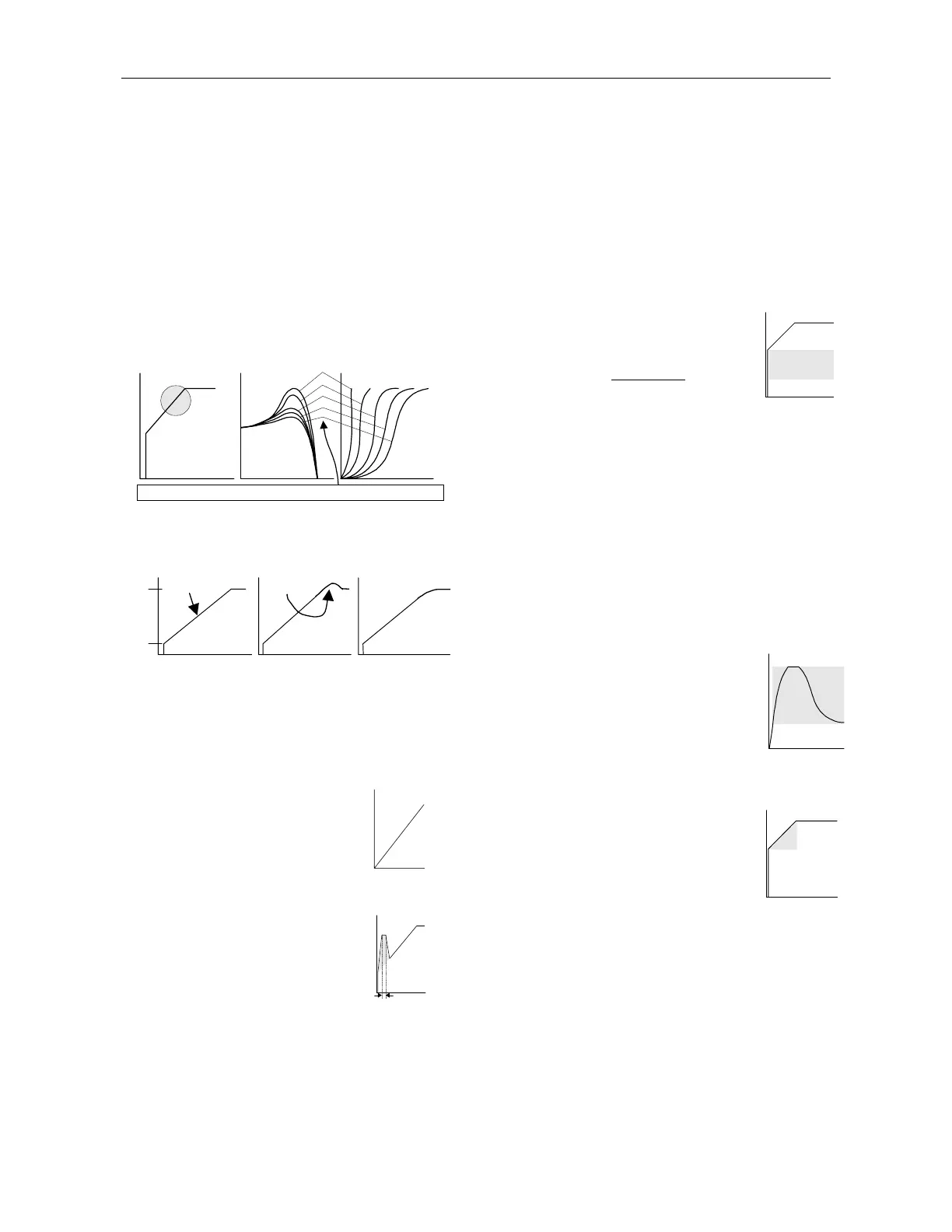

Pump Control – Start Curves

Induction motors produce peak torque of up to 3 times

the rated torque towards the end of starting process. In

some pump applications, this peak may cause high

pressure in the pipes.

The RVS-DN incorporates 4 different starting curves:

Start Curve 0 – Standard curve (Default). The most

stable and suitable curve for the motor, preventing

prolonged starting and motor overheating.

Start Curves 1, 2, 3 – During acceleration, before

reaching peak torque, the Pump Control Program

automatically controls the voltage ramp-up, reducing

peak torque.

Choice of three pump control acceleration curves 0, 1!!, 2!!, 3!!

Speed

Time

TorqueVoltagae

DOL

0

1!!

2!!

3!!

Start Curve 4 (Torque) – Torque Controlled

acceleration, provides a smooth time controlled torque

ramp for the motor and the pump.

Time

Torque

Peak over speed (Torque)

acceleration

IV

Tn

Time = t1

Time < t1

Time > t1

Slight time increase

smoothes the Peak

Linear Torque

increase

Idea

Conditions

Note: Always starts with Start Curve 0. If

towards end of acceleration, peak torque

is too high (pressure is too high), proceed

to Curve 1, 2, 3 or 4 if necessary.

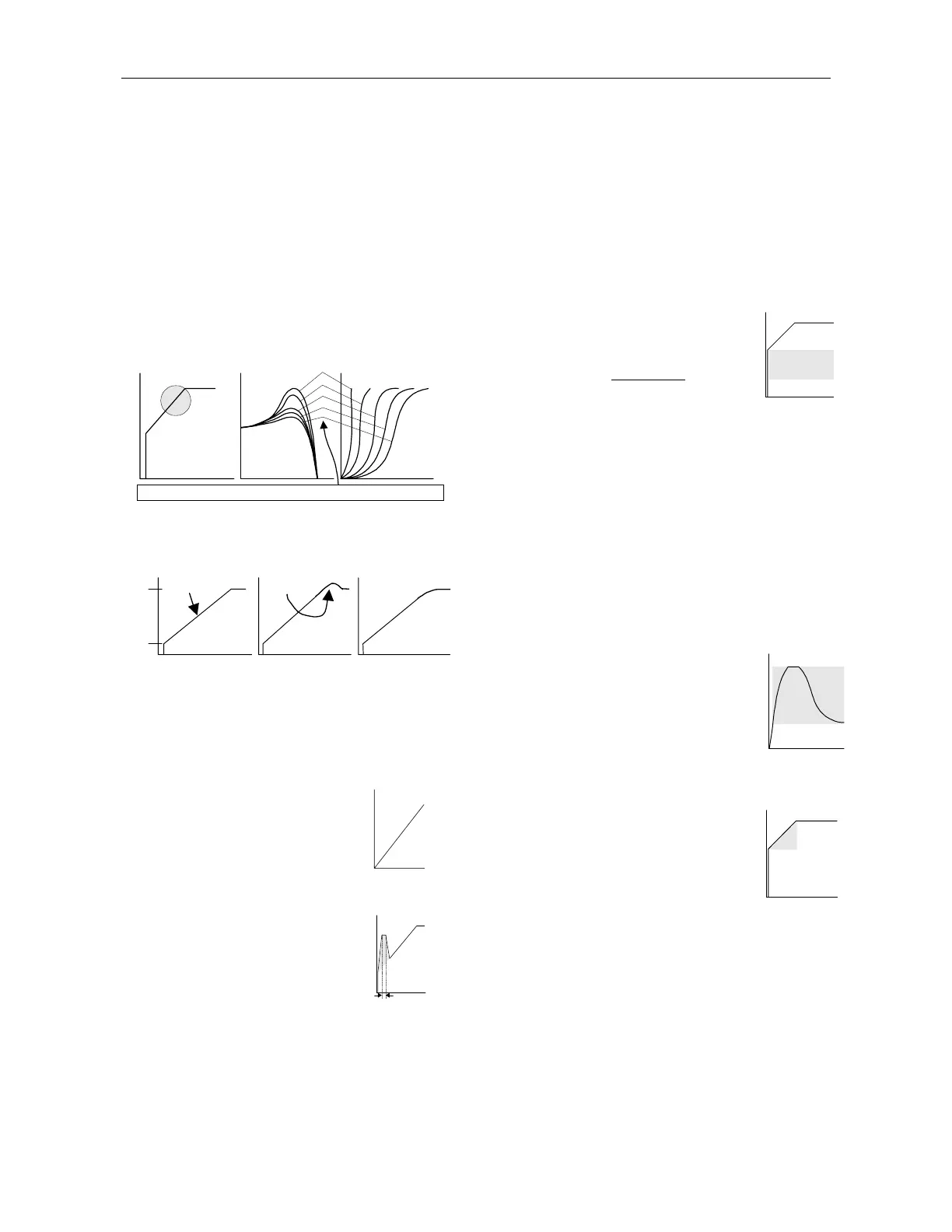

Tacho Feedback, 0-10VDC (Optional)

Provides linear acceleration and

deceleration curves according to

rpm feedback. 12 tacho gain levels

can be selected for closed loop

control starting and stopping.

Note:

Consult factory for additional

information.

Motor Voltagae

+10Vdc

S

eed RPM

Un

Pulse Start

Intended to start high friction loads,

requiring high starting torque for a

short time.

A pulse of approx. 80% Un without

Current Limit is initiated to break

the load frees. Pulse duration is

adjustable, 0.1 – 1 sec.

+10Vdc

0.1 - 1 Sec.

Un

80%

After this pulse, the voltage is ramped down to Initial

Voltage setting, before ramping up again to full voltage

according to Start Parameters settings.

Initial Voltage

Determines motor’s initial starting torque (the torque is

directly proportional to the square of the voltage).

Range: 10-50% Un (consult factory for extended

range). This adjustment also determines the inrush

current and mechanical shock. A setting that is too high

may cause high initial mechanical shock and high

inrush current (even if Current Limit is set low, as the

Initial Voltage setting overrides Current Limit

setting).

A setting that is too low may result

in prolonged time until motor

begins to turn. In general, this

setting should ensure that the motor

begins turning immediately

after

start signal.

U%

10%

50%

100%

Current Ramp (Initial Current)

Determines initial Ramp-Up starting Current. When

desired, increase Initial Voltage to Max. (50% or 80%

respectively). The LCD displays “Initial Current” and

the starter will linearly Ramp Up the current following

the desired acceleration time. Range: 100-400%

Current limit

Determines motor’s highest current during starting.

Range 100-400% of FLA setting (consult factory for

extended range). A too high setting will cause greater

current drawn from main and faster acceleration.

A setting that is too low may

prevent motor from completing

acceleration process and reaching

full speed. In general, this setting

should be set to a high enough

value in order to prevent stalling.

Note: Current limit is not operating

during Run and Soft stop.

I%

400%

100%

Acceleration Time

Determines motor’s voltage ramp-

up time, from initial to full voltage.

Range 1-30 sec. (consult factory for

extended range). It is recommended

to set Acceleration Time to the

minimum acceptable value (approx.

5 sec).

U%

1

100%

30 sec

Notes:

1. Since Current Limit overrides Acceleration

Time, when Current Limit is set low, starting

time will be longer than the preset

acceleration time.

2. When motor reaches full speed before voltage

reaches nominal, Acceleration Time setting is

overridden, causing voltage to quickly ramp-

up to nominal.

3. Using starting curves 1, 2, 3 prevents quick

ramp up.

Loading...

Loading...