Pump Control

32

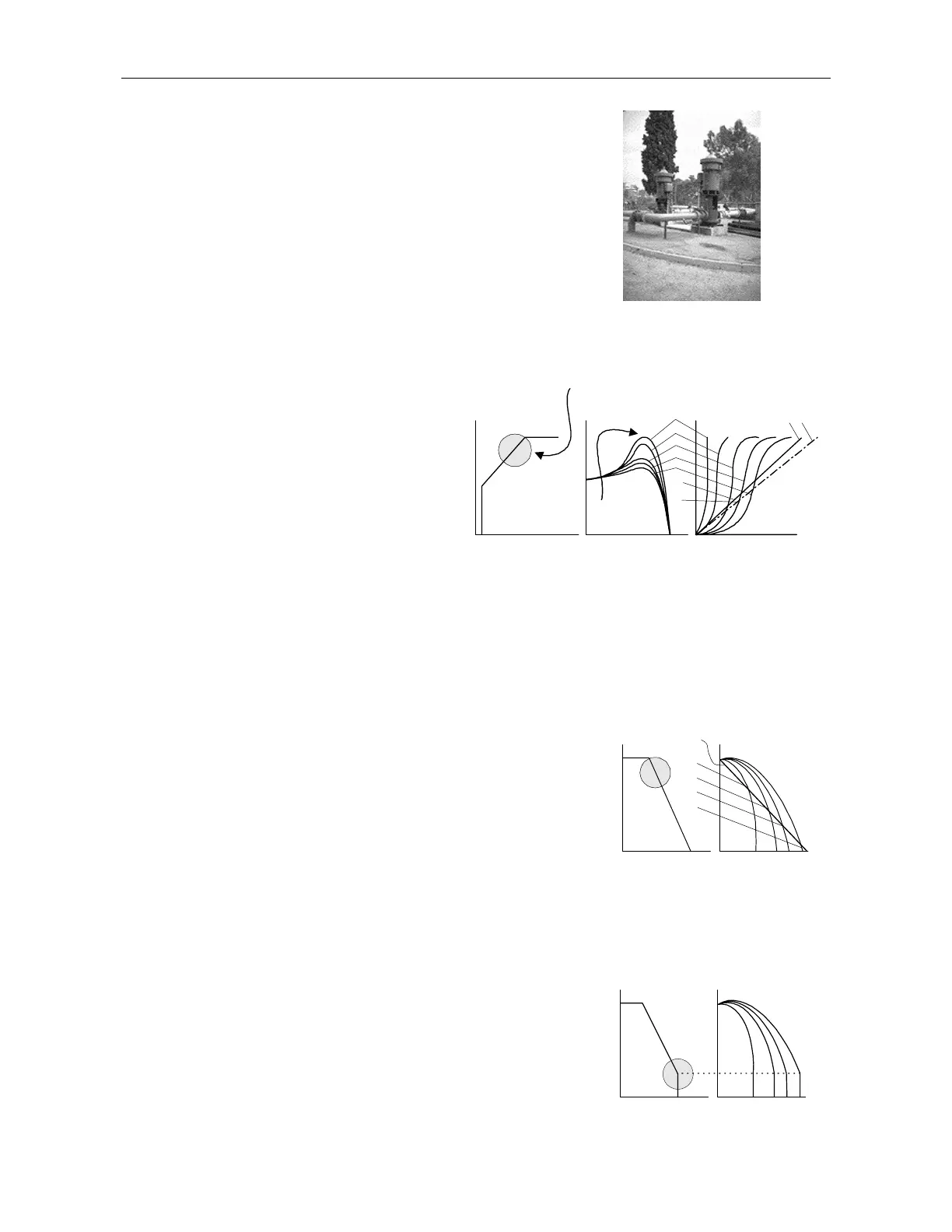

Choosing a suitable Pump Curve (centrifugal Pumps)

Starting Curve

1. Adjust main parameters as necessary (FLA, FLC, etc..)

2. Set Starting Curve, Acceleration Time, Current Limit, and Initial

Voltage to their default values (curve 0, 10 sec., 400% and 30%

respectively).

3. Start the pump while watching the pressure gauge as the pump starts

and look for overshooting (“Pressure Surge”) of the gauge needle

above the target pressure. In case of over pressure, choose a peak

torque reduction curve (Pump Control curve 1!).

4. Set Start Curve 1!, increase Acceleration Time

to 15 sec. and reduce Current Limit to 350%.

Start the pump and watch the pressure gauge

while the pump starts.

5. In most cases, overshooting is reduced, if the

overshoot persists, increase Acceleration time to

25 sec. (confirm with motor manufacturer) and

try again.

6. If the overpressure persists, increase Starting

Curve setting to 2!, 3!, 4 (Torque) or 5 (Current

Ramp) if necessary. Each increase in Starting

Curve setting will reduce the Peak Torque, thus,

reducing the overpressure and preventing the

“Pressure Surge” during start.

7. To increase starting time above these

maximums, employ “Special Starting” (page

32) with these techniques or incorporate Torque

and Current characteristics.

Pump control during

operating area

Speed

Sec

TorqueVoltagae

DOL

0

1

2

3

Peak

Torque

4

5

4 5

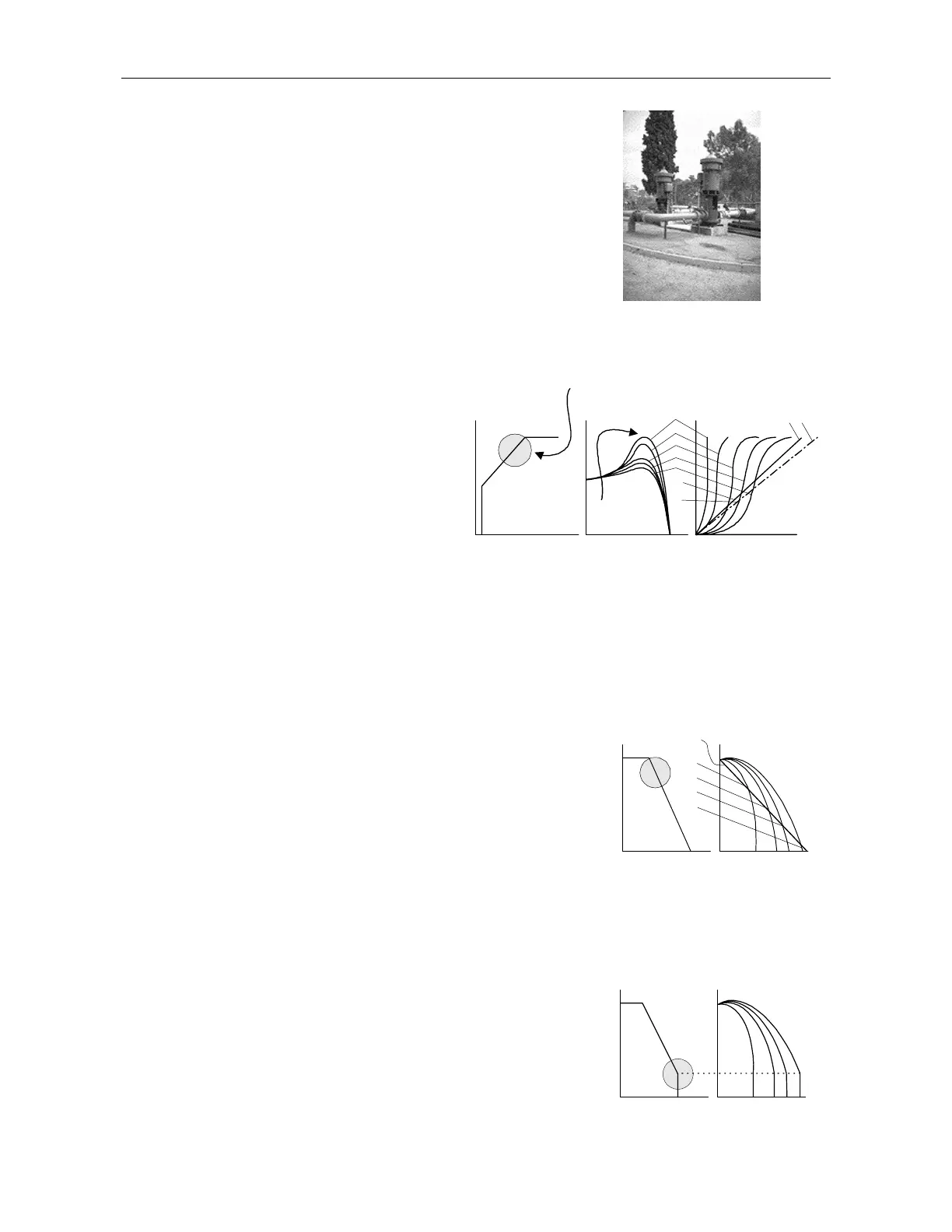

Stopping Curve

1. Adjust main parameters as necessary (FLA, FLC, etc..)

2. Set Stop Curve and Deceleration Time, to their default values (curve

0, 10 sec., respectively).

3. Stop the pump, watching the pressure gauge and the check valve as

the pump stops. Look for undershooting/overshooting (“Water

Hammer”) of the gauge (which may abruptly stops the pump and the

motor).

4. Select Stop Curve 1, increase Deceleration time to 15 seconds. Stop

the pump and watch the pressure gauge and the rate of closing of the

check valve as the pump stops. Abrupt stopping of the pump and motor

will cause a loud audible noise emitted from the check valve.

5. In most cases, “Water Hammer” is reduced. If the “Water Hammer”

persists, increase the time to 25 seconds (confirm with motor

manufacturer) and try again.

6. If the “Water Hammer” persists, increase Stop Curve setting to 2!, or

3!. Each increase in stop curve will reduce the abrupt stop of the pump,

thus, preventing the “Water Hammer” phenomenon.

7. If the extent of the water hammer was not reduced, increase to stop

curve # 4 to employ Torque Controlled deceleration.

Voltage Deceleration

1

0

2

3

4

Final torque during soft-stopping a pump motor

1. While decelerating, the check valve may close before Deceleration

Time has elapsed, thus, allowing current to flow through stator winding

causing unnecessary heat. Select Final Torque sensitivity to 1, and stop

the pump, confirm that current stopped flowing through the motor

shortly after the check valve closed.

2. If current still flows more than 3-5 seconds after check valve closure,

increase Final Torque up to 10 if necessary, to stop current flow earlier.

Voltage Deceleration

SecFT1

FT10

Loading...

Loading...