• While cropping please pay attention to ensure that the residue material discarded does not fall

on any people in the vicinity. (If necessary, please make arrangements to provide protection

against spraying of the residue material)

• Please take care when cropping with expanded fitting that you do not hold the fittings in the

region in which they spread out. (Hazard of injury during the punching process while pressing

the two parts of the fitting)

• When working with the fitting cropper, please wear safety goggles

9.2 Maintenance

• 1. The fitting cropper UNI – POWER works primarily without the need for maintenance. What

must be paid attention to is merely regular checking of the filter regulator based on the

compressed air quality, since dirt on the filter element could lead to a slowdown in the

cropping process. Similarly, if the condensate is not discharged regularly, the cropping

cylinder could get dirty and thus wear out faster.

• 2. Another point with respect to maintenance is regular topping up of oil in the cropping

cylinder. One can see when oil needs to be topped up when the cropping cylinder cannot

move out to its complete stroke or the screw sinking cannot be spread. Under these

circumstances, the following needs to be done.

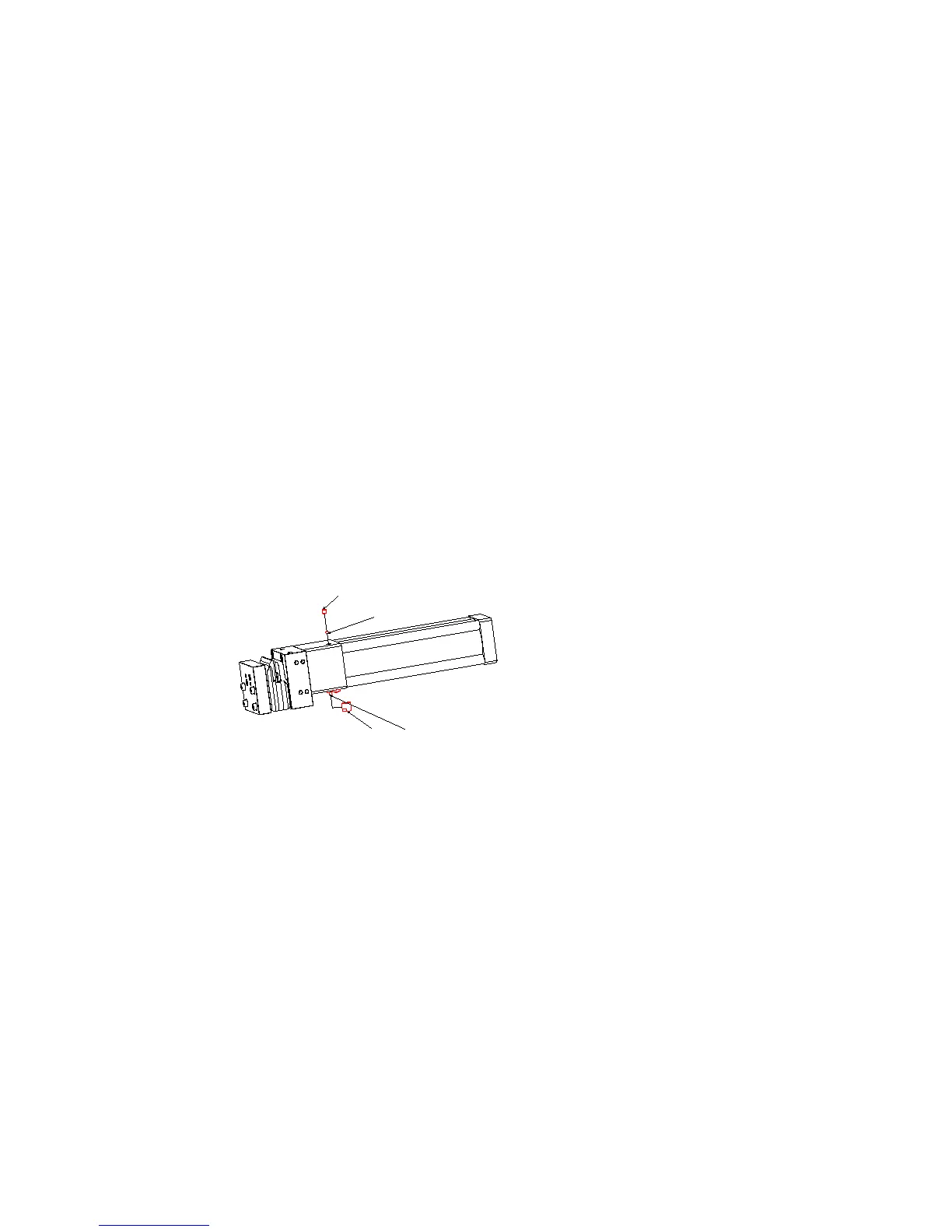

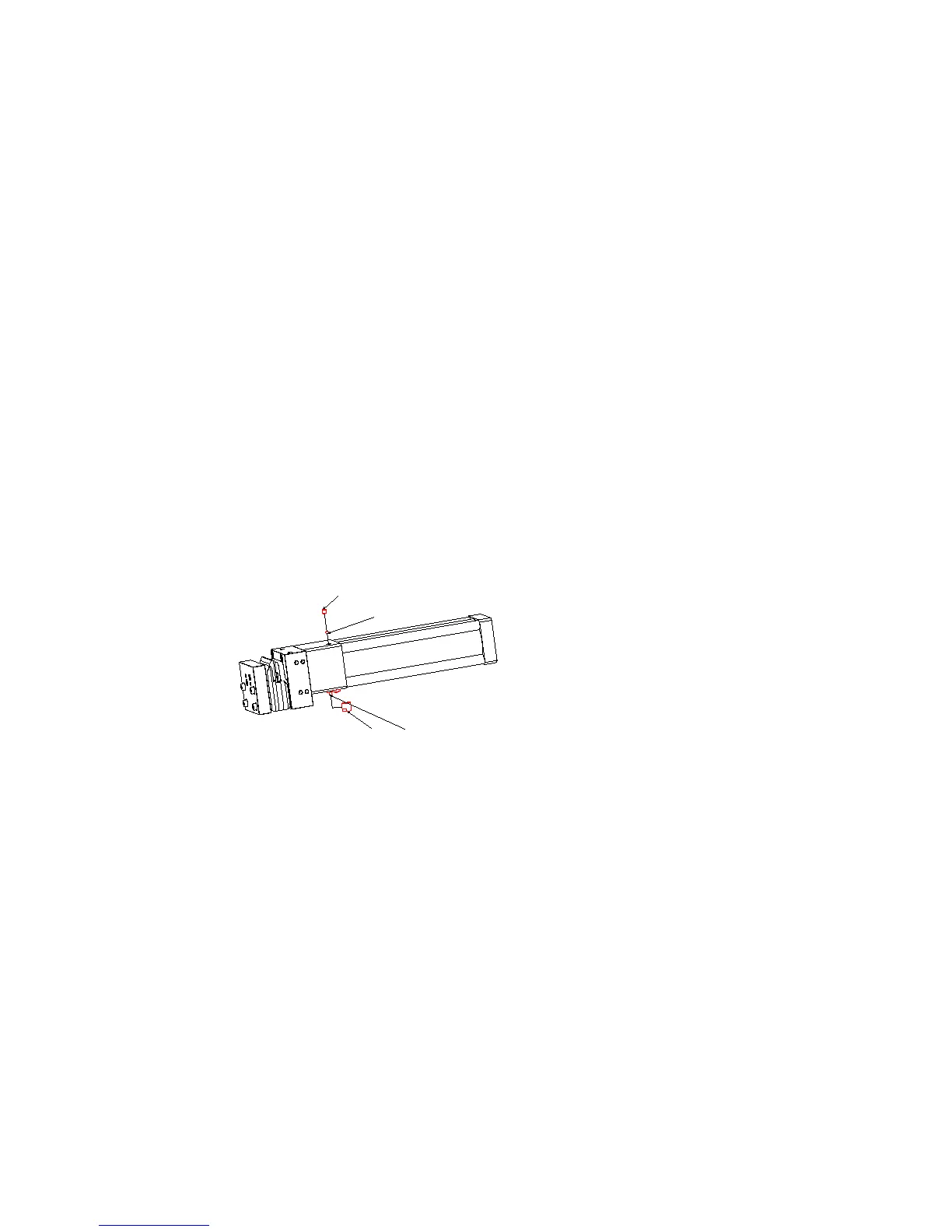

51

55

47

50

Unscrew the protective cap 51 from the nipple 47 and fill up oil using an oil press till such time

that the cutting punch 9 moves slightly with the drill punch 10. It must be paid attention to here

that the compressed air supply to the cropping cylinder is not switched off and that it is in its

base position. Similarly, care must be taken to ensure that the oil press does not suck in any

air. If, inadvertently, too much oil has been filled up, and/or there is air trapped in the cylinder

after filling up the oil, then the oil can be discharged or air removed by opening the screw 55.

However, when doing so, it must be noted that the oil remains under pressure and the

excess oil discharges quickly and / or the ball 50 under the screw 55 can get lost.

(Attention: Please wear safety goggles when releasing the oil!)

• 3. The maintenance of the tool consists of regular cleaning and oiling of the cutting punch

(pos. 7, 9 and 10) with a low viscosity cutting oil or cutting oil spray.

• 4. Changing the oil is not mandatory, and can be carried out as described below: Remove the

locking screw 55 with the ball 50, place the fitting cropper with the open bore over a container

to collect falling oil, and move the fitting cropper once slowly. The old oil is now pressed out of

Loading...

Loading...