Operation Manual – Spider ILD02 EFI

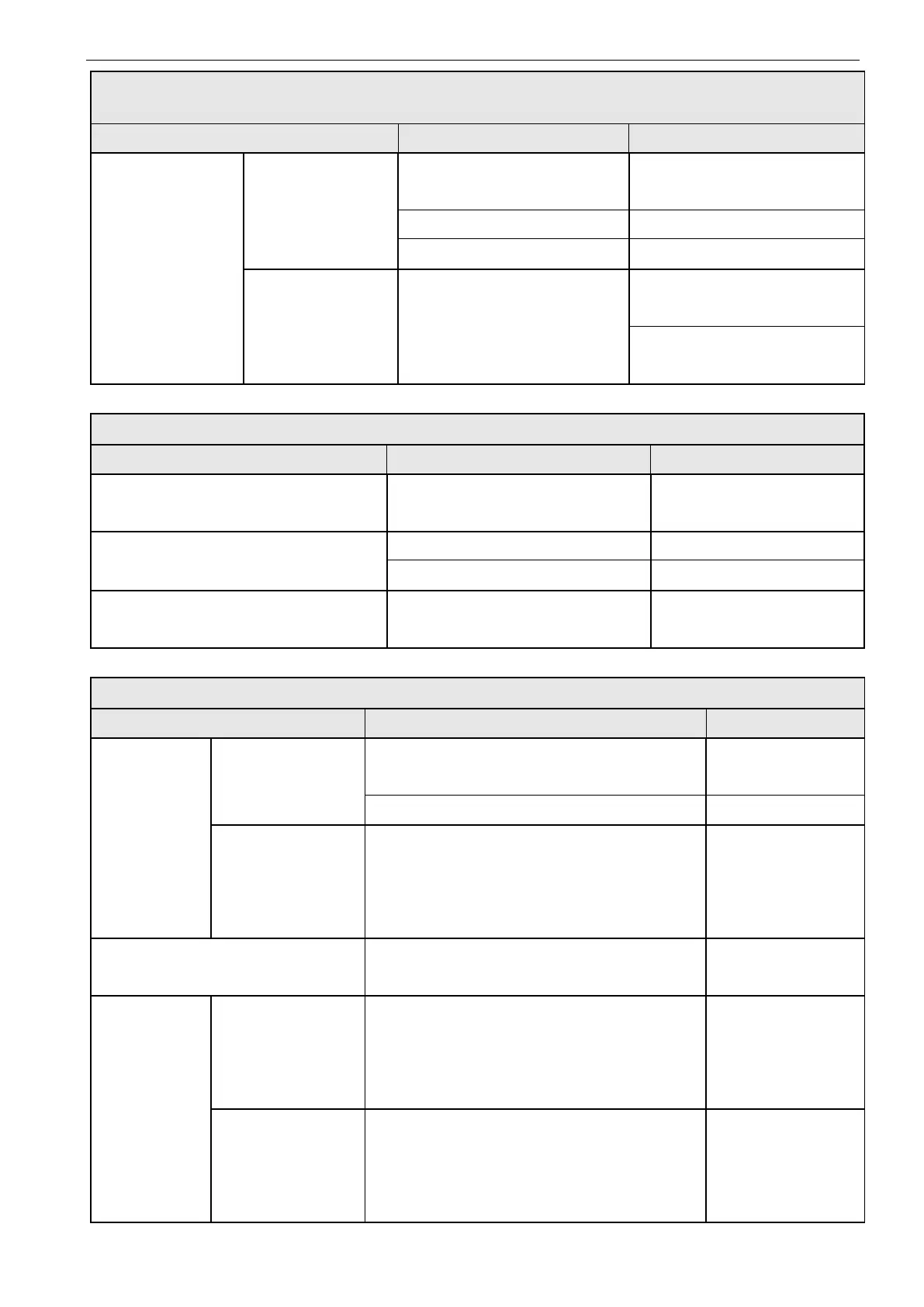

Problems with skid

steering

Skid steering does

not respond

Relay in the

elevation module

doesn't react

To large gap between Inductive

sensor and inductive segment

Set distance to 2mm, LED diode

on the sensor has to Light up

Inductive sensor is broken

Relay in the

elevation module

reacts

The skid steering valve doesn't

work

Check electrical contacts on the

on the valve unit

Replace the electromagnetic

valve unit

Problems with the elevation

Slow height change when changing

cutting height

One of the elevation servomotors is

broken

Check which of the servo

motors is broken and replace

Machin doesn't react to elevation

changes

Elevation module is broken

Elevation regulation does not stop

when at max or min height

one of the height sensors is broken

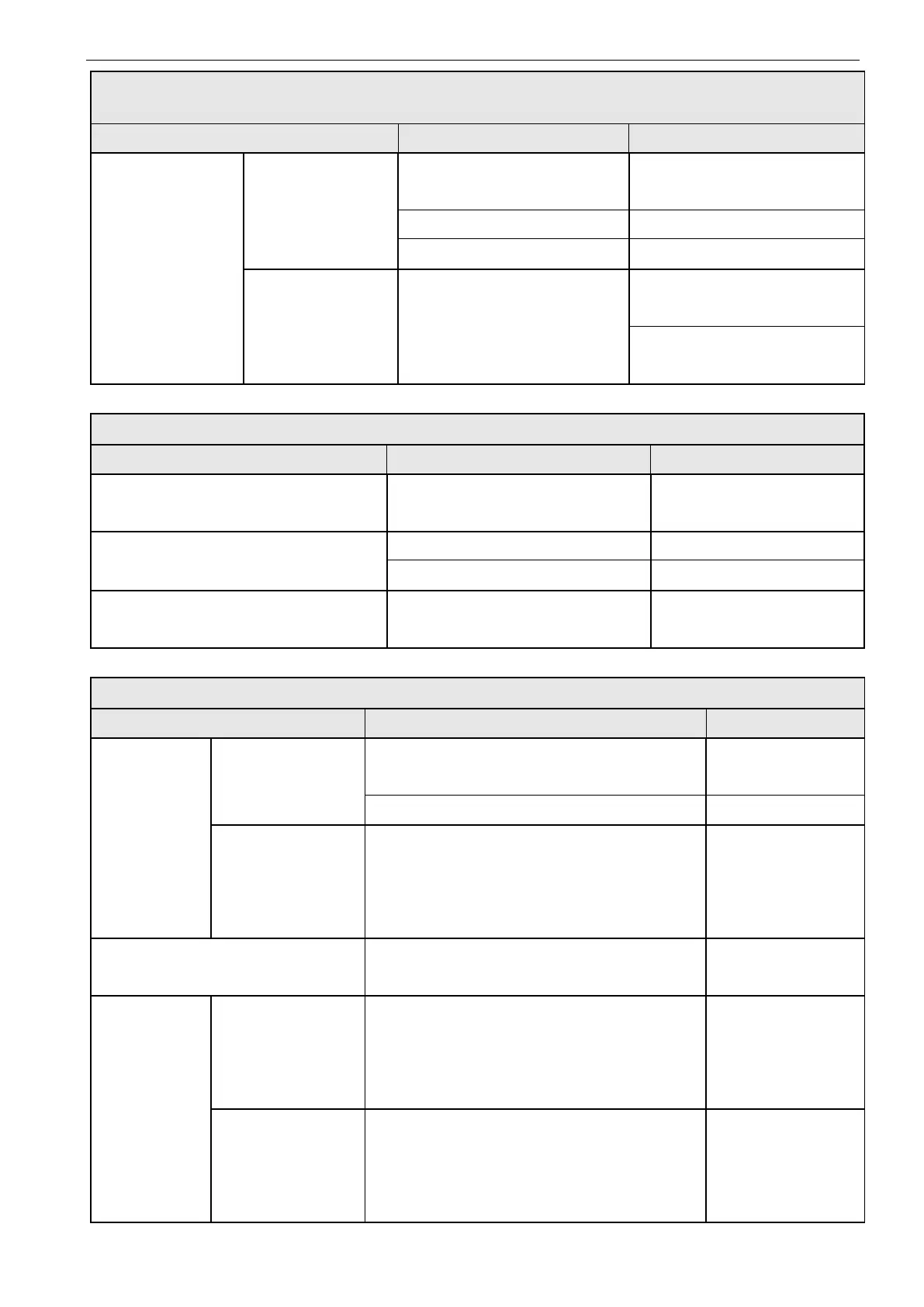

Issues with the remote control, and electrical system

Machine turns

of while

working

Interference

Transmitters)

Bad sparkplugs, interfere with the remote/unit

Machine cannot be

started (motor does

not turn, starter

relay does react)

The combination of a weak battery, a worn drive

servomotor can burn out the fuses for the

alternator

The machine keeps running for about

2 seconds after pushing the off button

Burned out ignition coils (often caused by

incorrect battery connection (swapping + for -))

battery is in bad shape, often caused by turning

the wheels while standing this overload the

alternator

Test the state of the

battery, replace a

bad battery. Steer

while moving.

Control unit 1x 40A

MAXI fuse

Extreme power consumption due to burned out

coils in the turning servomotor, under inflated

tyres

Replace drive

servomotor. Check

the tyre pressure as

prescribed

Loading...

Loading...