43

6.4.6.5 INPUT - TDS - CAL

The boiler must be at working temperature when calibrating a system. This is particularly

important if a temperature sensor is not fitted.

To ensure accuracy, the figures entered for both Set Point and Calibration must be greater

than 10% of the chosen range. For the best accuracy, calibrate the controller with the TDS as

close as possible to the Set Point. In some cases the boiler may need to be run for a period

of time to allow the TDS to build up before calibration. Recalibrate the boiler at the Set Point

once the boiler has settled down (after a few days in most cases). Check the calibration (as

close to the Set Point as is practical) weekly to ensure optimum performance.

Take a sample of the boiler water and measure its conductivity (in µS / cm) using a meter

such as the Spirax Sarco MS1. If the controller is required to be calibrated as neutralised

conductivity or TDS, neutralise the sample and measure again using the meter.

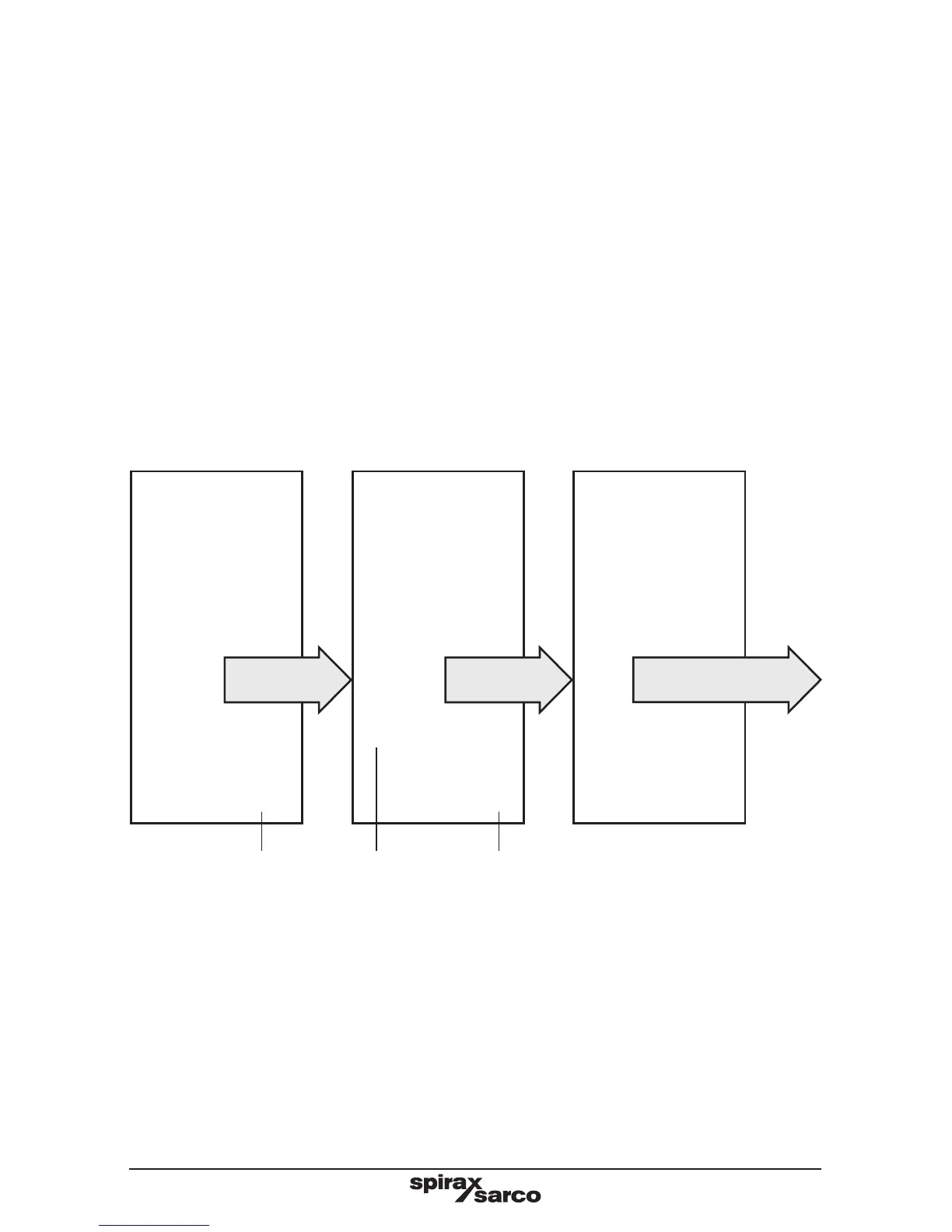

Enter the measured sample and press the ok button. 'CAL' will be displayed for the purge

time (if set) or for 1 minute (if purge = 0s). At the end of this period the calculated cell / probe

factor (K) will be displayed for 5 seconds. The menu will revert back to the normal run time

menu (PV) or if in commission menu, INPUT-TDS-CAL INT.

INPUT

TDS

CAL

(US / CM)

5010

INPUT

TDS

CAL

(US / CM)

V = 0.510

CAL..

INPUT

TDS

CAL

(US / CM)

K = 0.51

SAVED

Flashes

every

second

Enter the measured

conductivity /

TDS reading

See note

below

Exits automatically

after 5 seconds

Purge time

or 1 min

Press OK

Loading...

Loading...