OM600 ENGINE MECHANICAL 1B3-125

8. Turn over the cylinder head.

9. Remove the tensioning head (4) and valve seat ring (2)

with drift (14mm) and removal tool.

10. Clean the basic bore of valve seat ring.

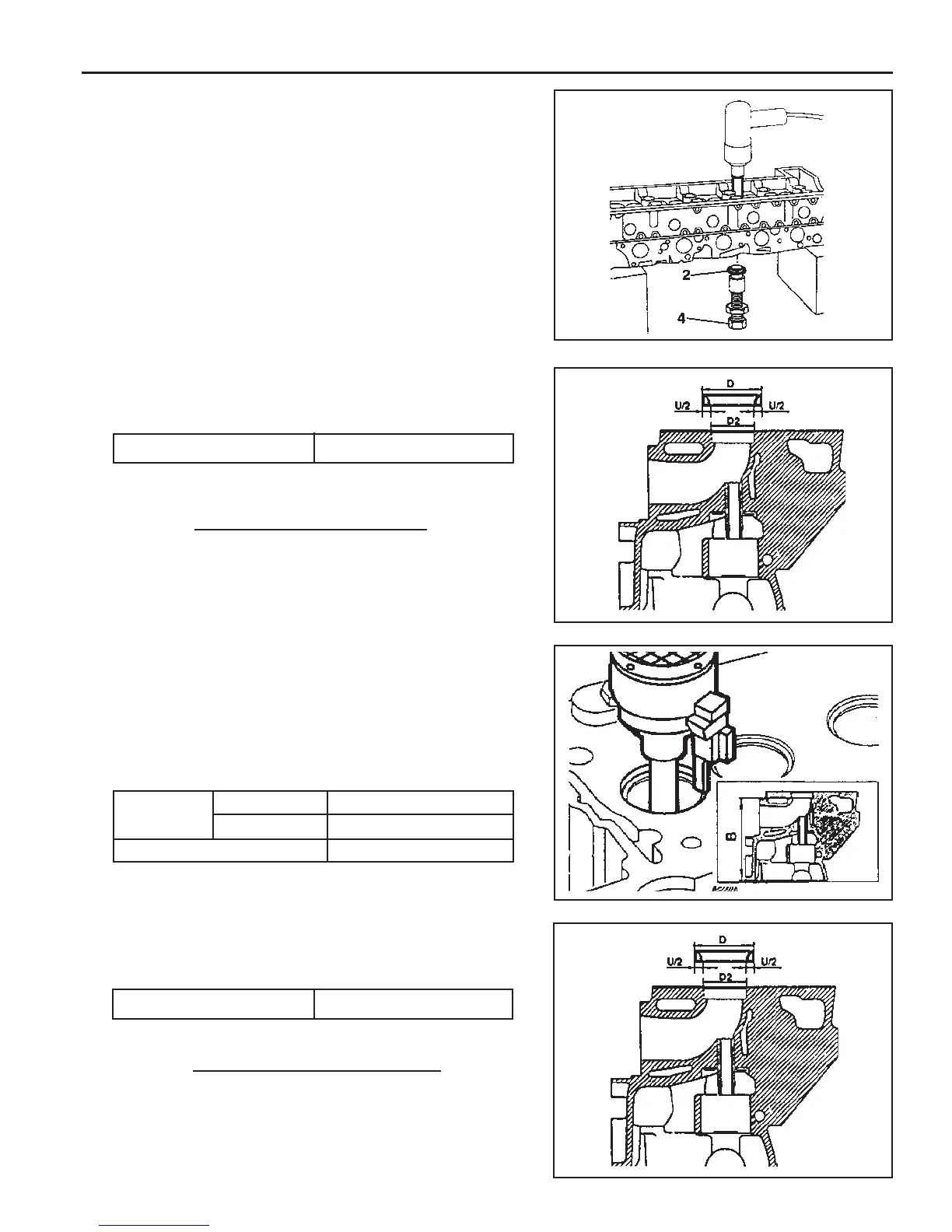

11. Measure the basic bore diameter (D2) and outer diameter

(D) of the new valve seat ring (standard size).

12. Calculate the overlap value ‘U’ (D - D2).

Overlap Value ‘U’ 0.068 - 0.100mm

Example) Measured value D = 37.100mm

Measured value D2 = 37.010mm

Overlap value ‘U’ = 0.090mm

If overlap value ‘U’ is out of standard, machine

the basic bore for the valve seat ring.

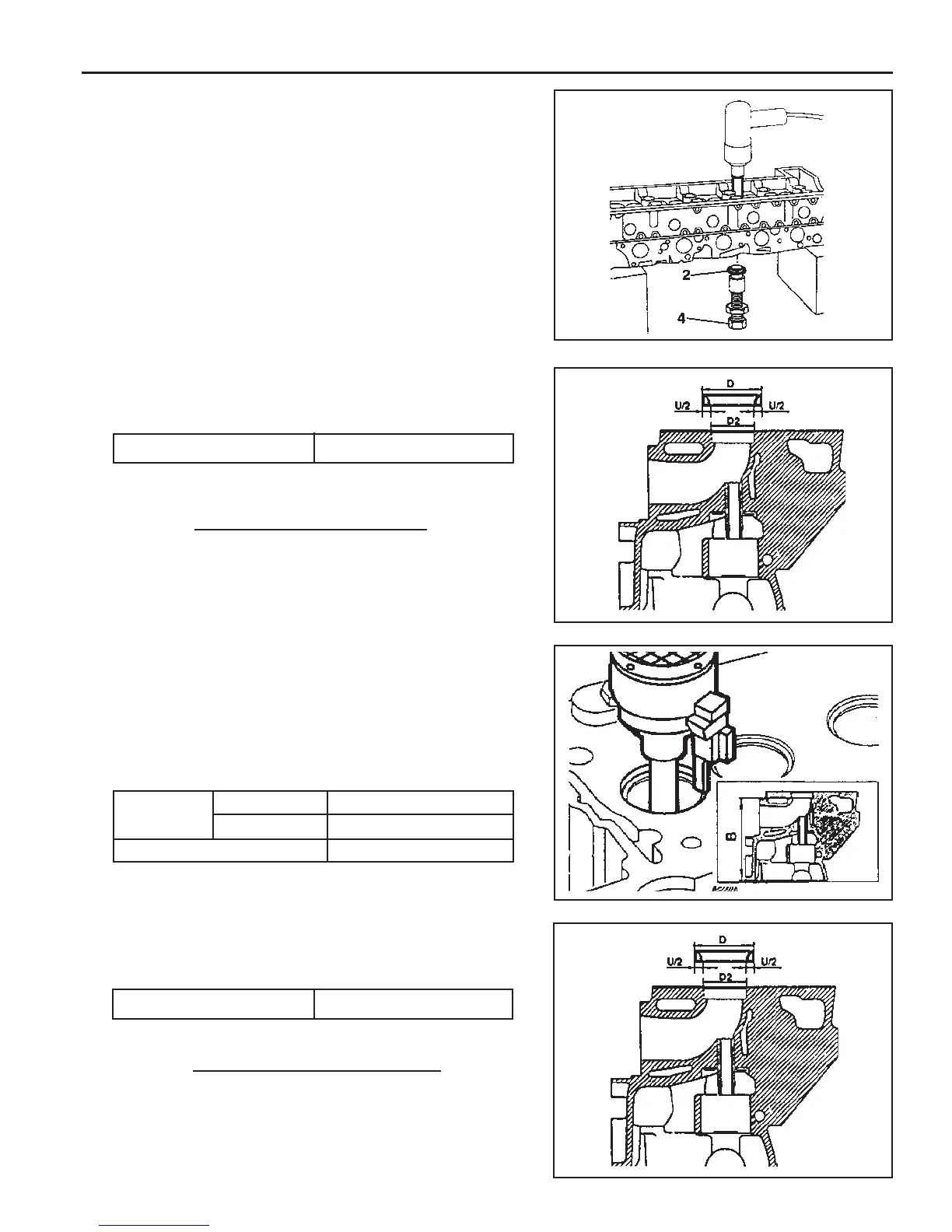

13. Clamp the cylinder head with clamping device.

14. Machining basic bore for valve seat ring (repair size).

Notice

Maintain minimum value of ‘B’.

- Machine the basic bore.

Limit

Intake

Exhaust

Max. D2

Min. B

40.516mm

37.516mm

133.4mm

- Measure machined basic bore and outer diameter ‘D’

of valve seat ring (repair size).

- Measure the overlap ‘U’

Overlap ‘U’ (D - D2) 0.068 - 0.100 mm

Example) Measured value D = 37.600 mm

Measured value D2 = 37.480 mm

Overlap U = 0.120 mm

The basic diameter D2 must be machined by

0.020mm in order to get the required overlap

value.

Loading...

Loading...