THIS APPLIANCE MUST BE CONNECTED TO A FULLY PUMPED SYSTEM.

6

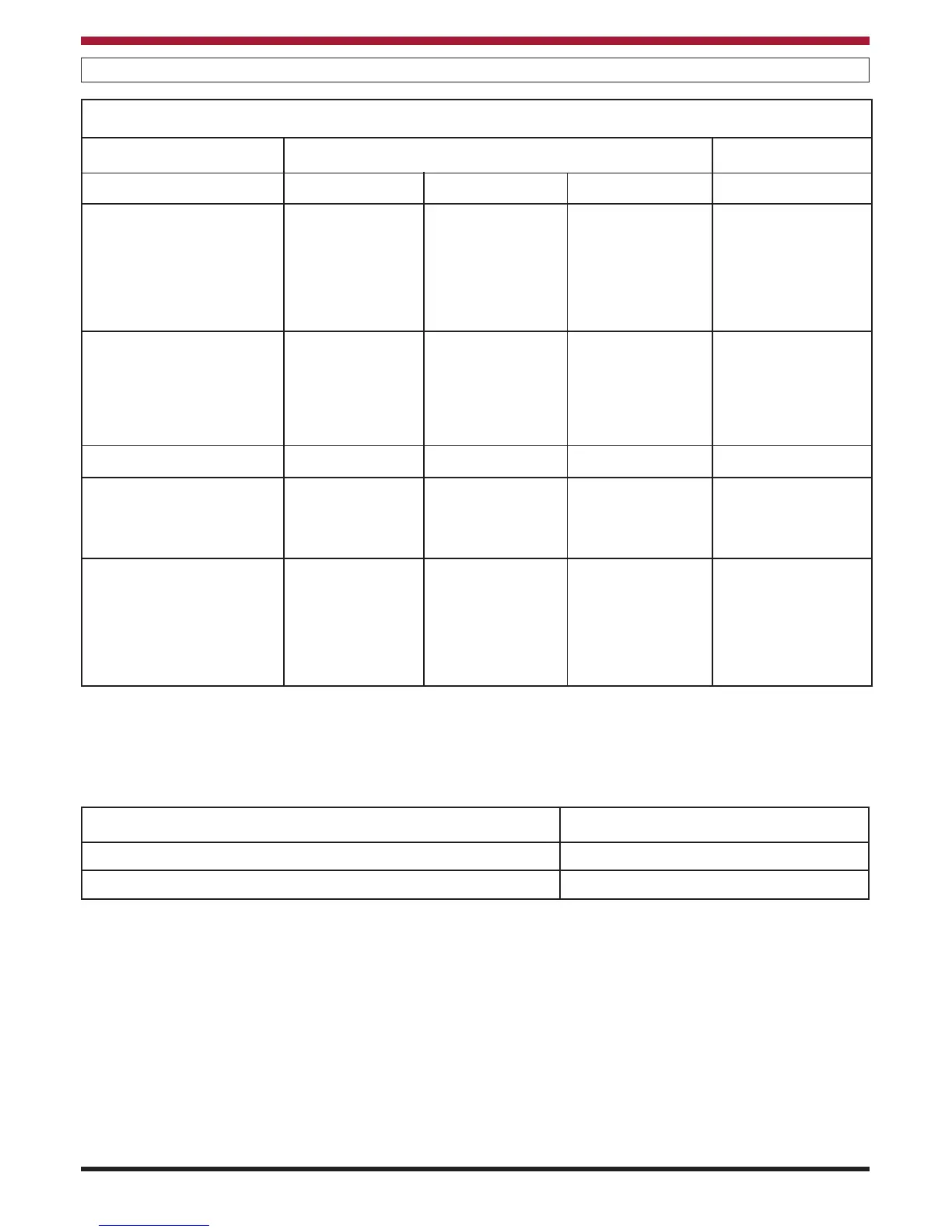

BURNER SPECIFICATION

BOILER BURNER COOKER BURNER

100K 80K 60K 100K/80K/60K

Burner Input

(kW)

Continuous Running 34.2 27.7 21.4 19.5

(kW) Cycling N/A N/A N/A 4.4

(Btu’s) Continuous Running 116,760 94,600 73,000 66,875

(Btu’s) Cycling N/A N/A N/A 14,950

Boiler Output

(kW) Continuous Running 29.3 23.5 17.6 2.1

(kW) Mean Cycling N/A N/A N/A 1.2

(Btu’s) Continuous Running 100,000 80,000 60,000 7,000

(Btu’s) Mean Cycling N/A N/A N/A 4,000

Nozzle 0.85 80

o

S (C.E.N) 0.65 80

o

S (C.E.N) 0.55 80

o

S (C.E.N) 0.5 60

o

S (C.E.N)

Pressure

(Bar) 7.4 7.4 7.1 7.1

(PSI) 107 108 103 110

Fuel Consumption

(L/Hr) Continuous Running 3.6 2.9 2.2 2.1

(L/Hr) Cycling N/A N/A N/A 0.47

US Gal/Hr

Continuous Running 0.95 0.77 0.58 0.55

US Gal/Hr Cycling N/A N/A N/A 0.12

All data are taken under laboratory conditions and may vary in use

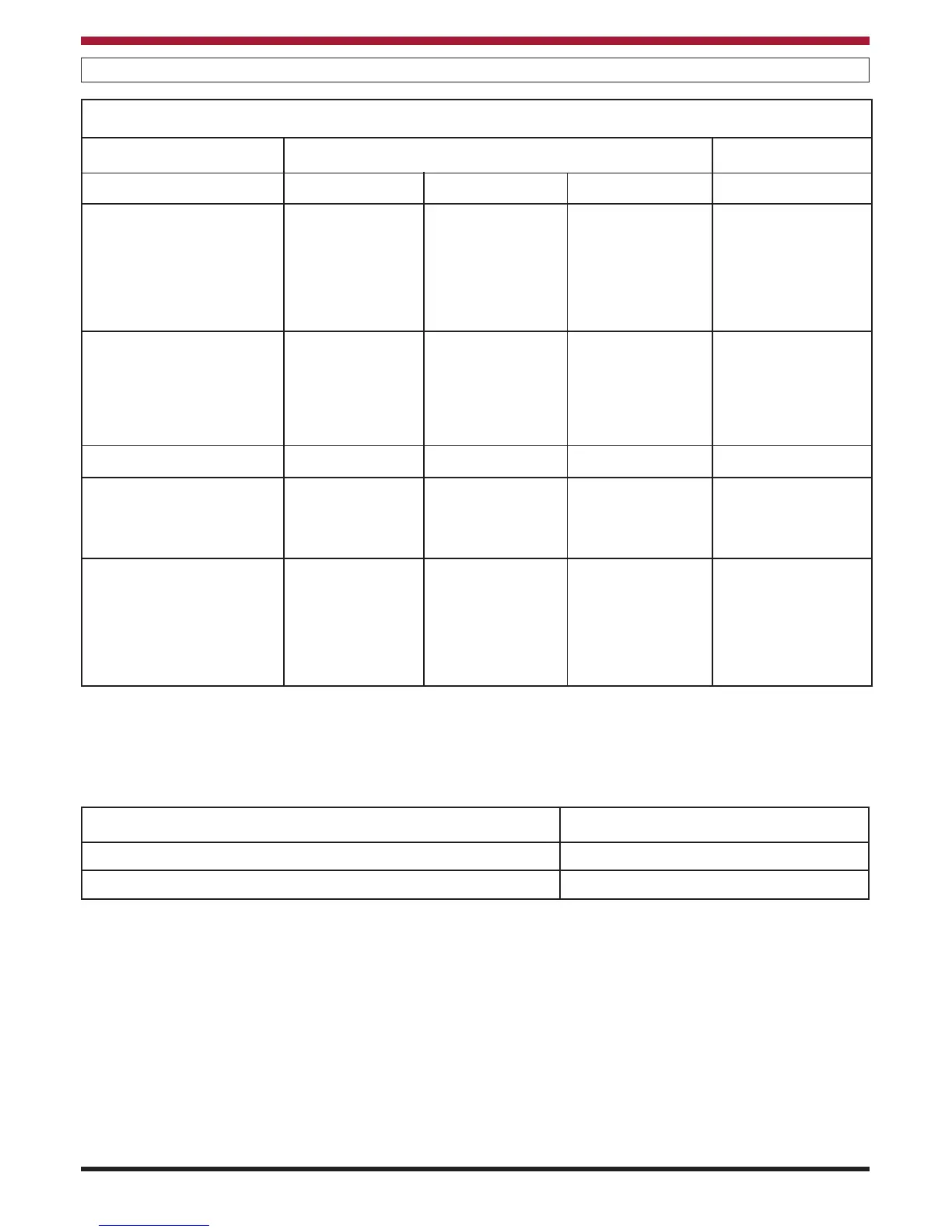

Design flow rate through the boiler 38.2 L/min / 8.4 Gpm

Static differential across the boiler 52.4 mbar / 21” wg

Dynamic pressure differential across the boiler 33 mbar / 13.23” wg

Differential Pressure Across the Boiler

Note: Design temperature differential across the boiler = 11°C (20°F)

Loading...

Loading...