ENGLISH • 31

9. NEVER run the workpiece between the fence and a

moulding cutterhead.

10. CUTTING THE WORKPIECE WITHOUT THE

USE OF A FENCE OR MITER GAUGE IS KNOWN

AS “FREEHAND” CUTTING. NEVER perform “free-

hand” operations. Use either the fence or miter gauge

to position and guide the workpiece.

11. HOLD THE WORKPIECE FIRMLY against the miter

gauge or fence.

12. CUTTING COMPLETELY THROUGH THE WORK-

PIECE IS KNOWN AS “THROUGH-SAWING”.

Ripping and cross-cutting are through-sawing

operations. Cutting with the grain (or down the length

of the workpiece) is ripping. Cutting across the grain

(or across the workpiece) is cross-cutting. Use a fence

or fence system for ripping. DO NOT use a fence or

fence system for cross-cutting. Instead, use a

miter gauge. USE PUSH STICK(S) for ripping a

narrow workpiece.

13. AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where a sudden slip could cause a hand

to move into the blade.

14. KEEP ARMS, HANDS, AND FINGERS away from the

blade.

15. NEVER have any part of your body in line with the

path of the saw blade.

16. NEVER REACH AROUND or over the saw blade.

17. NEVER attempt to free a stalled saw blade without

first turning the machine “OFF”.

18. PROPERLY SUPPORT LONG OR WIDE workpieces.

19. NEVER PERFORM LAYOUT, assembly or set-up

work on the table/work area when the machine is

running.

20. TURN THE MACHINE “OFF” AND DISCONNECT

THE MACHINE from the power source before

installing or removing accessories, before adjusting or

changing set-ups, or when making repairs.

21. TURN THE MACHINE “OFF”, disconnect the

machine from the power source, and clean the

table/work area before leaving the machine. TURN

THE SWITCH IN THE “OFF” POSITION.

POWER CONNECTIONS

Before connecting the machine to the power line, make

sure the switch (s) is in the “OFF” position and be sure

that the electric current is of the same characteristics as

indicated on the machine. All line connections should

make good contact. Running on low voltage will damage

the machine.

Danger! Do not expose the machine to rain or operate

the machine in damp locations.

Before connecting the machine to the power source, make

sure the switch is in the “OFF” position.

ASSEMBLY

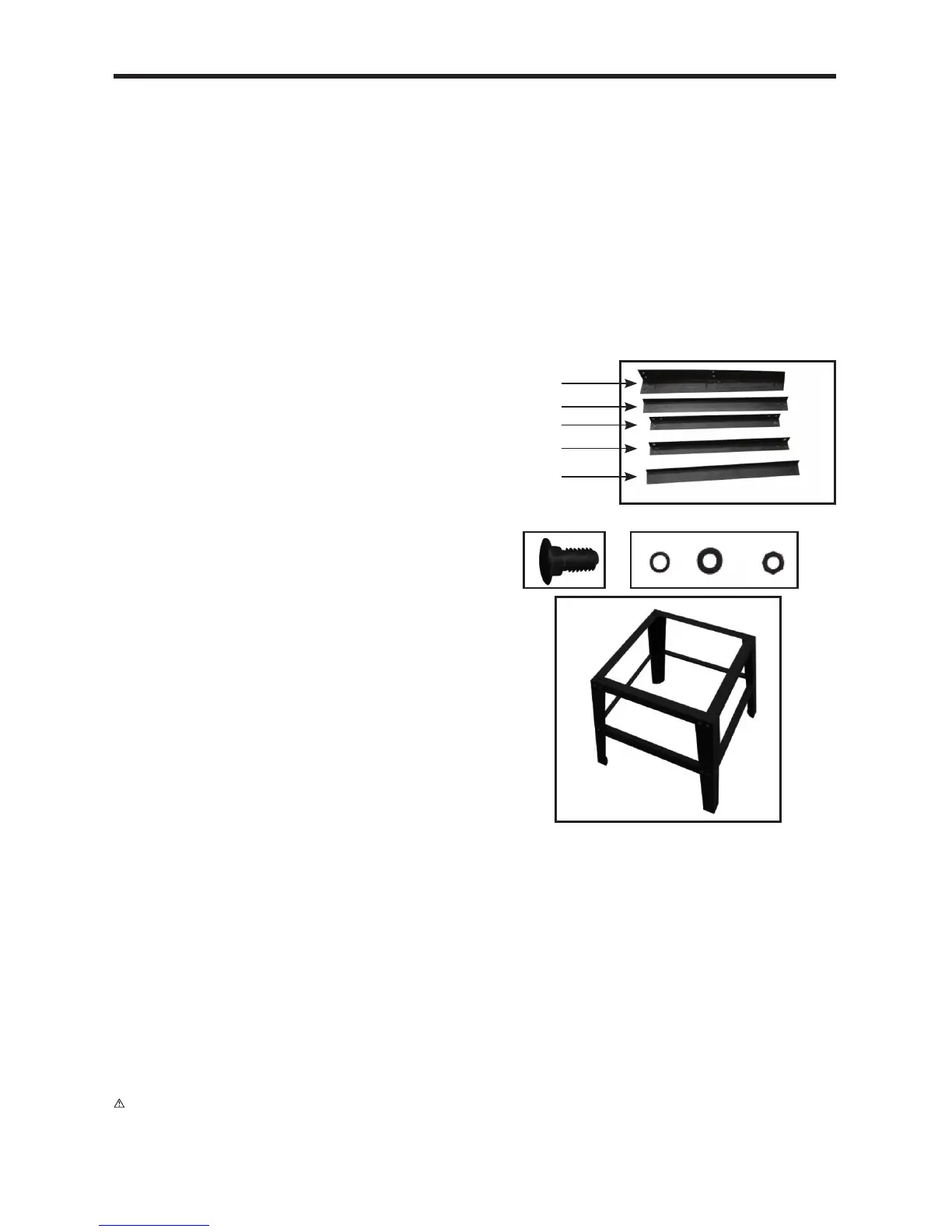

Assembly of the leg stand

When assembling the stand, it is recommended that the

screws are only lightly tightened until the stand is fully

assembled.

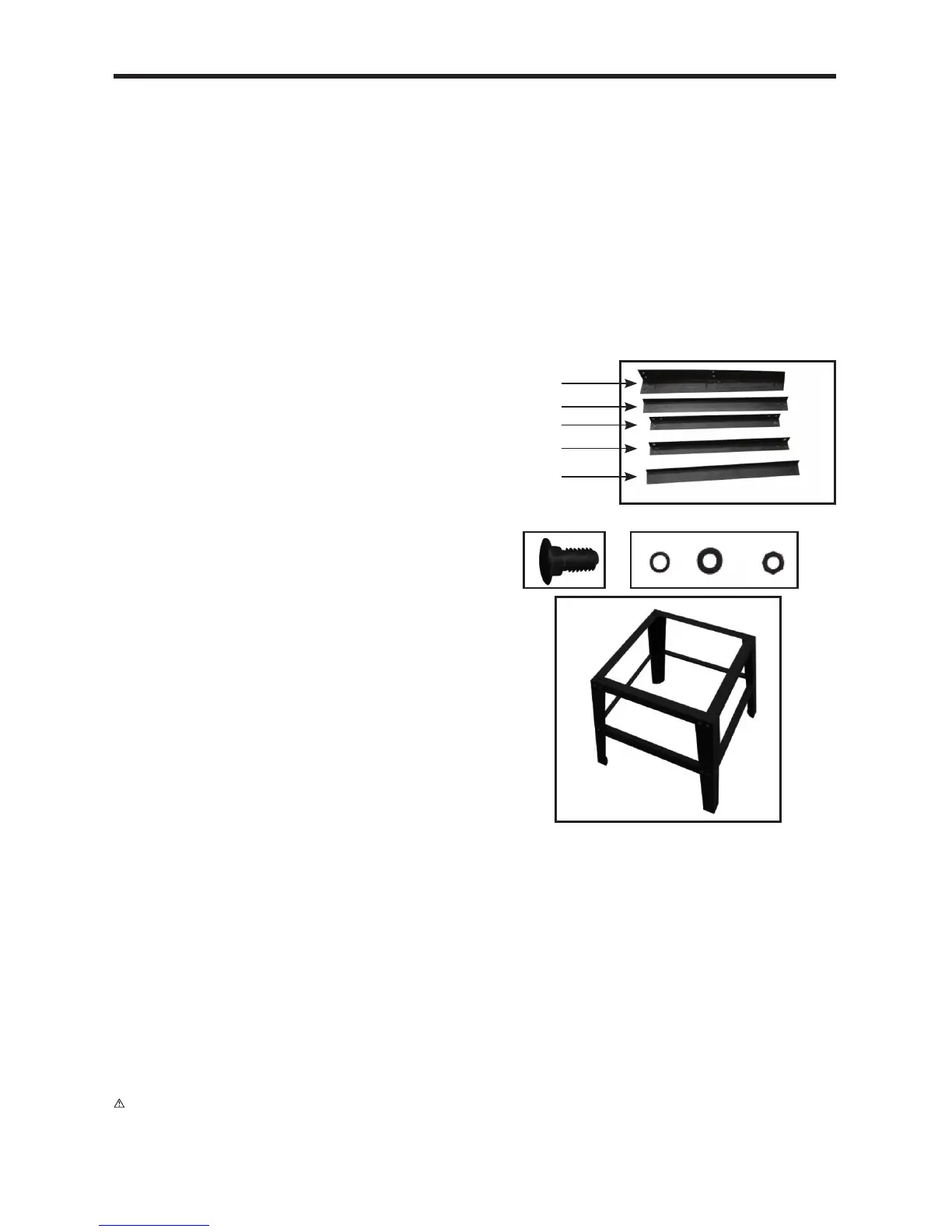

1. Identify the parts and fittings

Before you start the assembly of the stand’s legs, fully

unpack the saw and lay out the individual parts.

Clearly identify the parts shown in Fig. A1 and A2,

including the fittings. Group these parts together and

ensure that you have the correct quantity of all the

pieces shown.

2. Assemble the stand’s legs

Step 1

Select the following parts:

2 x Part 1

1 x Part 3

1 x Part 5

Lay the parts together as shown in Fig. B1, B2, and

B3. This is best done by simply laying the parts

loosely together on the floor. Once you are satisfied

that you have the parts correctly laid together, start

the fitting process.

Align the holes and secure with the bolts (a) as shown

in Fig. B1.

DO NOT fully tighten the bolts, nuts and washers at

this point. Finger tight is sufficient.

Bolt Washer Nut

A1

1 x 4 pieces

2 x 2 pieces

3 x 2 pieces

4 x 2 pieces

5 x 2 pieces

A2

5

5

3

3

1

1

1

1

2

2

4

4

Loading...

Loading...