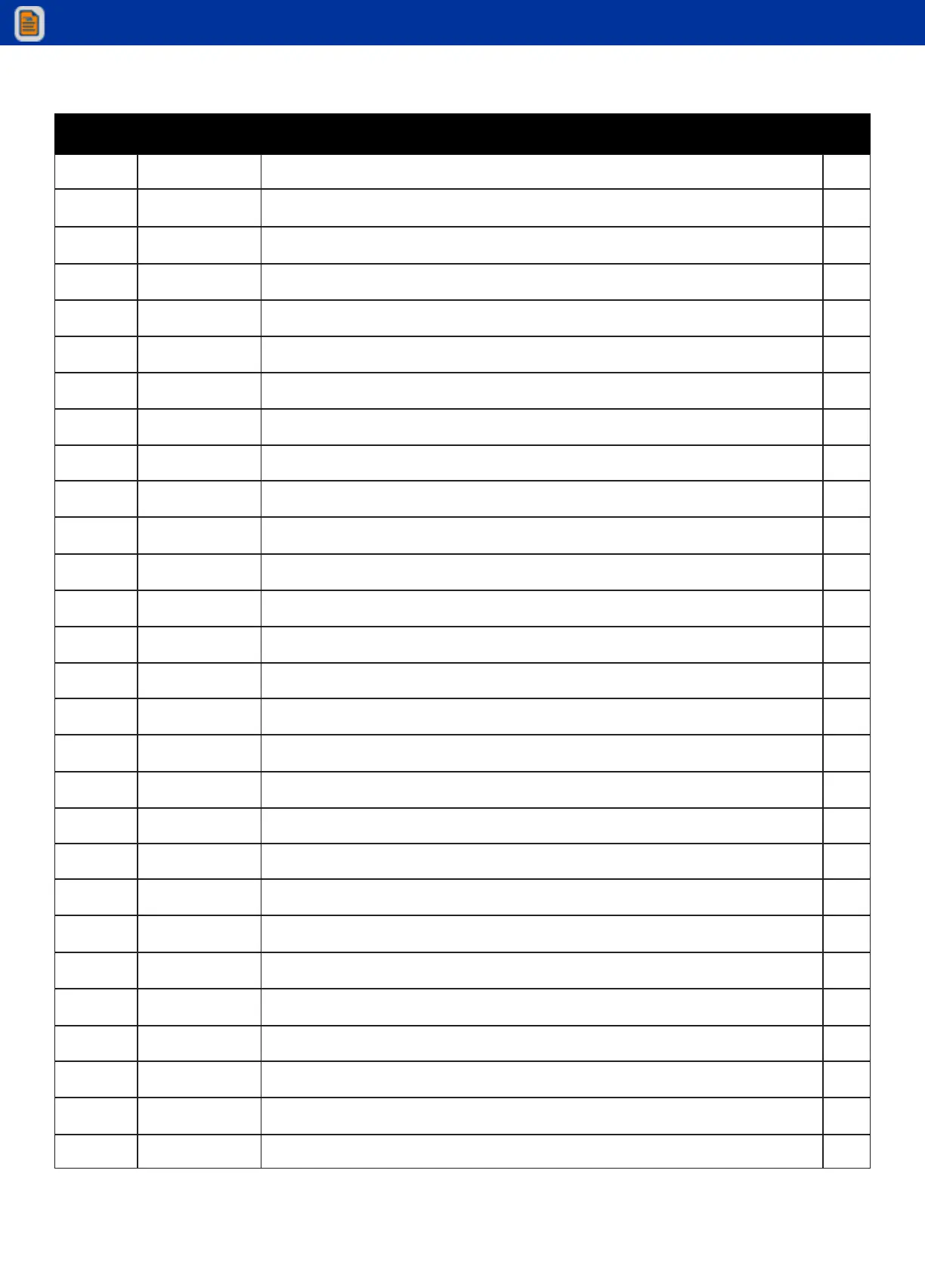

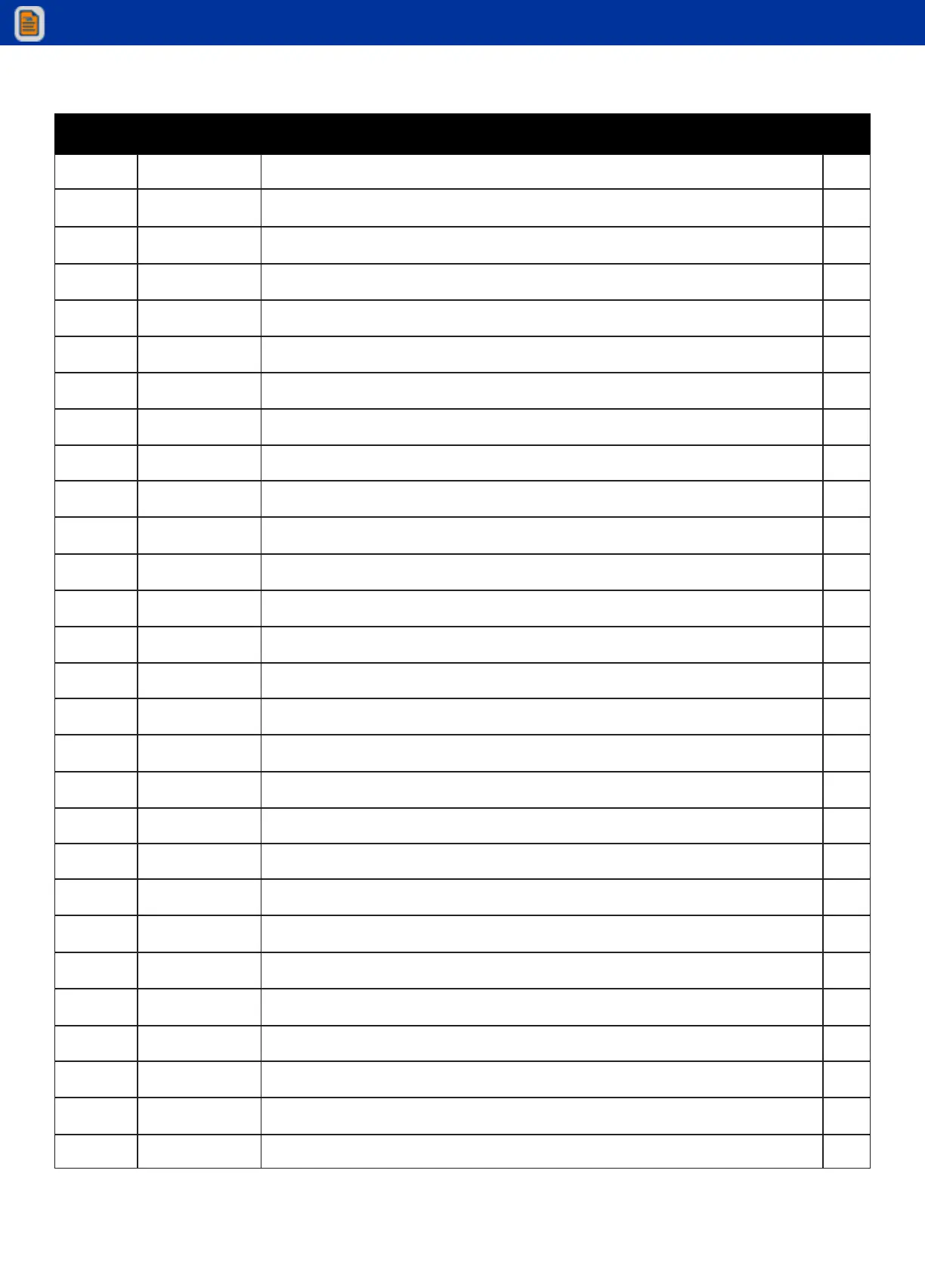

Maintenance 15

Quarterly Inspection Continued...

Frequency

Q

Q

Q

Q

Q

Q

Key

Hyd Lines

Pumps&Motors

Valves

Cylinders

Winch

Hyd Filter

Inspection Description

Hoses, fittings, & tubing for proper routing, leakage, blistering, deformation,

& excessive abrasion.

Pressure line(s) from pump to control valve

Return line(s) from control valve to reservoir

Suction line(s) from reservoir to pump

Pressure line(s) from control valve to each function

Load holding valve pipe(s) and hose(s)

Other

Pumps and motors for loose bolts/fasteners, leaks, noise, vibration, loss of

performance, heating and excess pressure.

Winch motor(s)

Rotation motor(s)

Other

Hydraulic valves for cracks, spool return to neutral, sticking spools, relief

valve failure.

Main control valve

Load holding valve(s)

Outrigger or auxiliary control valve(s)

Other

Hydraulic cylinders for drifting & leakage. Rods for nicks, scores, & dents.

Castor damage. Case & rod ends for damage & abnormal wear.

Outrigger cylinder(s)

Inner boom cylinder(s)

Outer boom cylinder(s)

Extension cylinder(s)

Rotation cylinder(s)

Jib lift cylinder(s)

Jib extension cylinder(s)

Other

Winch, sheaves, & drums for damage, abnormal wear, abrasion, & other

irregularities.

Hydraulic filters for replacement per maintenance schedule.

Status

Loading...

Loading...