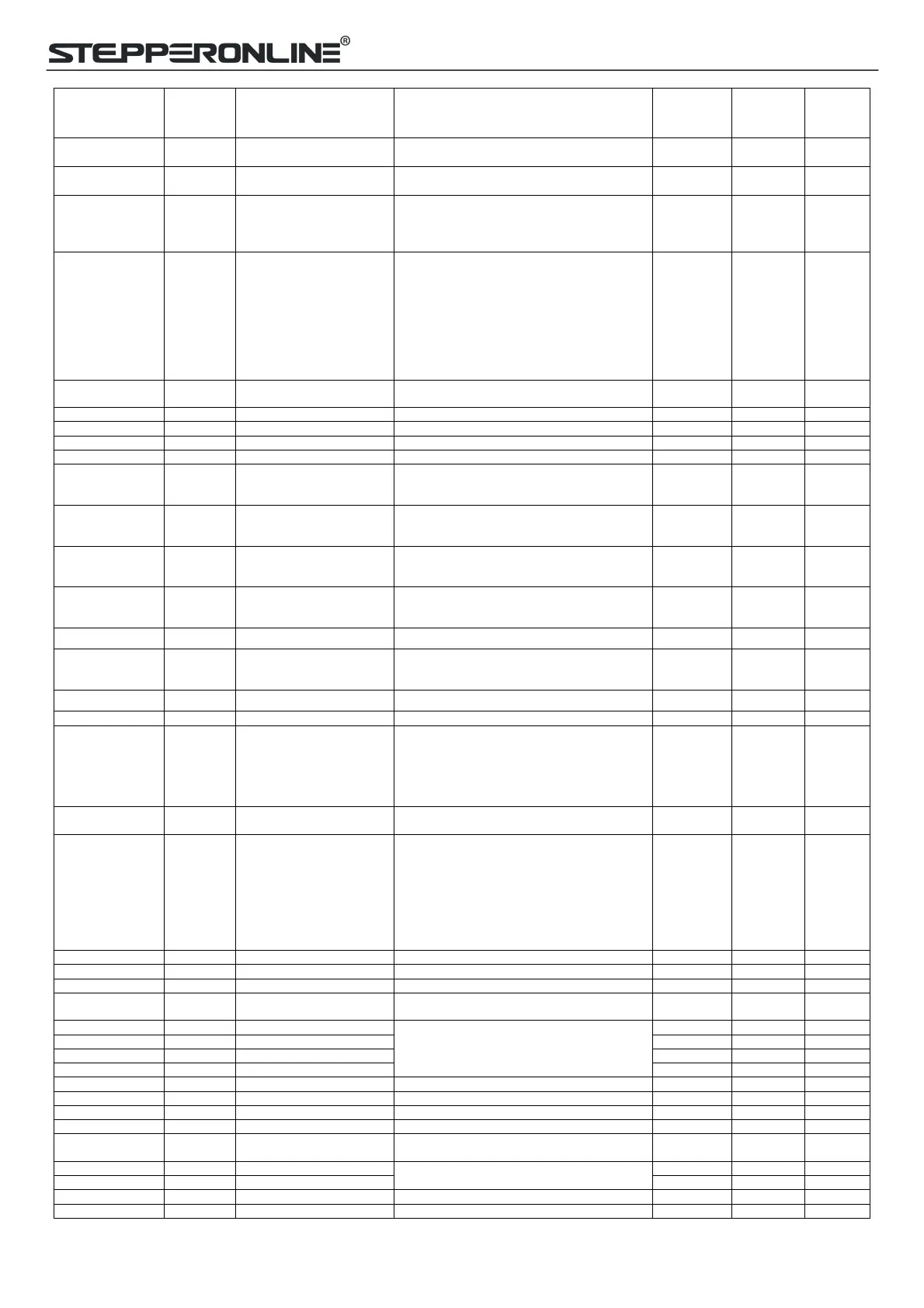

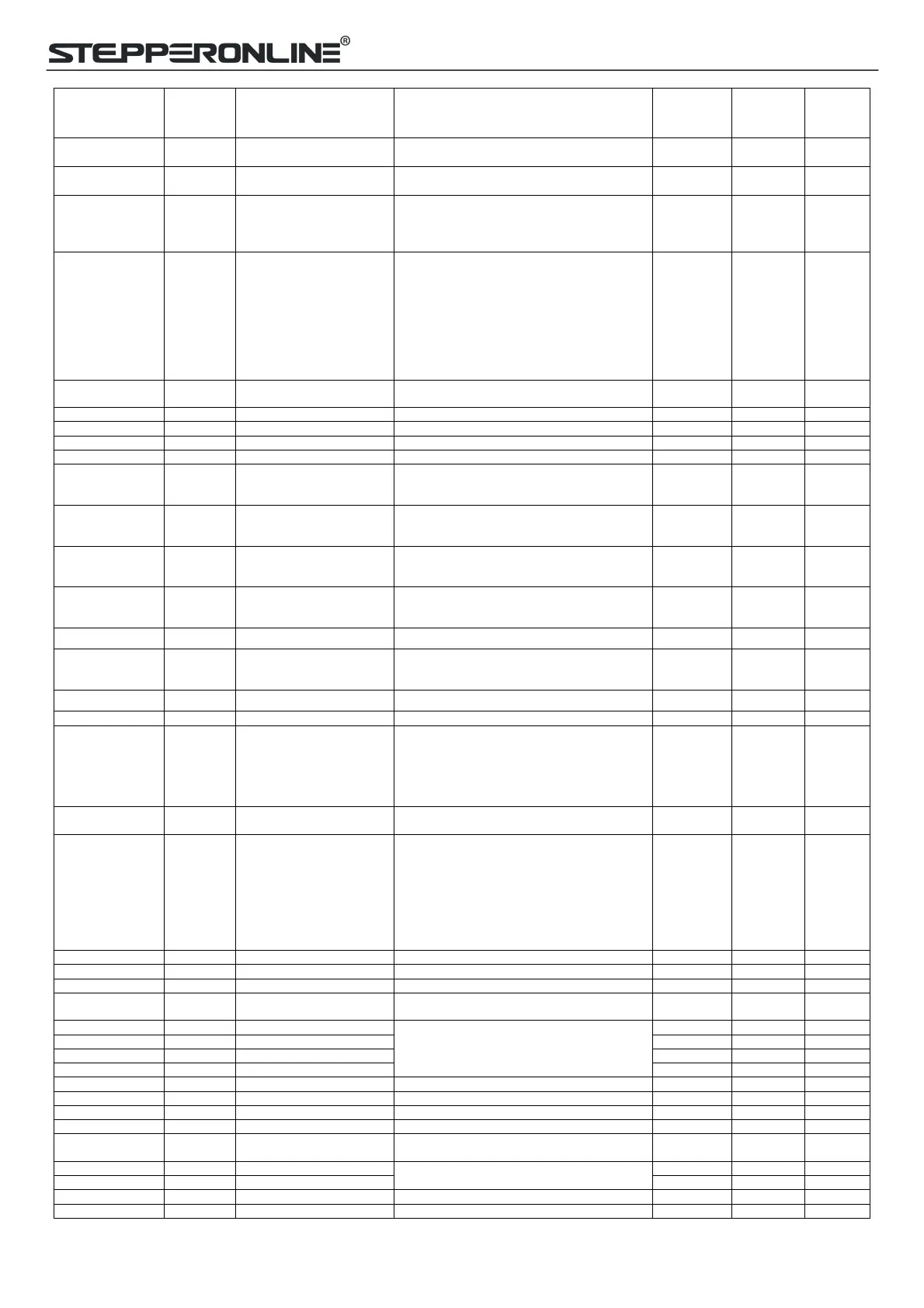

CLRS Series RS485 Closed Loop Stepper Drive User Manual

0x23: in-position completed;

0x24: brake output;

0x25: alarm output;

Threshold value of brake

locking velocity

Alarm detection selection

Bit setting:

=1: Yes; =0: No

bit0: over-current (Cannot be changed)

bit1: over-voltage

bit2: position following error

bit3: ADC sampling failure

bit4: Locked shaft alarm

bit5: EEPROM alarm

bit6: Auto-tuning alarm

Distance to send "In

Position" output signal

The distance (in number of pulses) to send out

the In-Position signal

Approximately equal to motor phase current

value multiplied by 1.2 -1.4

503: 3-30

507: 5-70

1008: 5-80

Percentage of holding

current in closed-loop

mode

It is recommended to keep default, If the

torque is not enough, it can be increased

appropriately

Percentage of holding

current in open-loop mode

It is recommended to keep default, If the

torque is not enough, it can be increased

appropriately

Percentage of shaft locked

current(power on)

Rising time of shaft locked

current (power on)

0: 2400 1: 4800 2: 9600 (default)

3: 19200 4: 38400(factory) 5: 57600

6: 115200

When SW6 and SW7 are all OFF, it can be set

by PC software.

When SW1 - SW5 are all ON, it can be set by

PC software

RS485 data type selection

0: 8-bit data, even check, 2 stop bits;

1: 8-bit data, odd check, 2 stop bits

2: 8-bit data, even check, 1 stop bit;

3: 8-bit data, odd check, 1 stop bit:

4: 8-bit data, no check,1 stop bit:

5: 8-bit data, no check,2 stop bits;

Switching time to standby

Standby current

percentage

This JOG is triggered by RS485.

For JOG triggered by IO, please use

Pr8.40/8.41

Current loop proportional

KP

It is recommended to keep the factory value,

when disable auto-tuning, can be modified

Loading...

Loading...