TS 440

English

22

appropriate Assigned Protection Factor.

If you are unable to determine the water

flow rate, to reduce the risk of serious or

fatal respiratory illness or cancer the

operator and any bystanders should

always wear a properly rated, NIOSH-

approved respirator with an Assigned

Protection Factor sufficient to provide

the level of respiratory protection

needed for worksite- specific conditions.

Points to be noted with diamond and

composite cutting wheels

Object to be cut

– Must be fully supported

– Must be secured so that it cannot

roll or slip away

– Must be protected against vibration

and movement

The cutting sequence

There are many ways to cut materials

and objects with a cut-off machine and

the operator and/or his supervisor, with

knowledge of the job site conditions and

requirements, always must exercise

good judgment and discretion in

determining how to safely complete a

cutting task. The methods described in

the following sections, while constituting

proven techniques, are illustrative only

and are not meant to substitute for the

judgment of the experienced workmen

with direct knowledge of on-site

conditions.

However, the cutting sequence is

important. The last cut must always be

made in such a way that the cutting

wheel cannot become pinched, bound

or clamped and so that the operator, co-

workers and bystanders are not at risk of

being injured by a falling part that has

been cut off or out, or by cutting debris or

sparks.

Leave small sections of uncut material to

hold the part being severed in position.

These sections can later be broken

through manually, using a hammer or

other appropriate tool. Always continue

to wear appropriate eye protection when

finishing a cut by breaking it manually.

A number of points must be decided

before the part is finally severed:

– How heavy is the part?

– In which direction can it move or fall

after being severed?

– Is it under tension?

– Is it properly supported to prevent

pinching or binding of the wheel?

The operator, co-workers and

bystanders must not be put at risk of

injury when the part is broken off or falls.

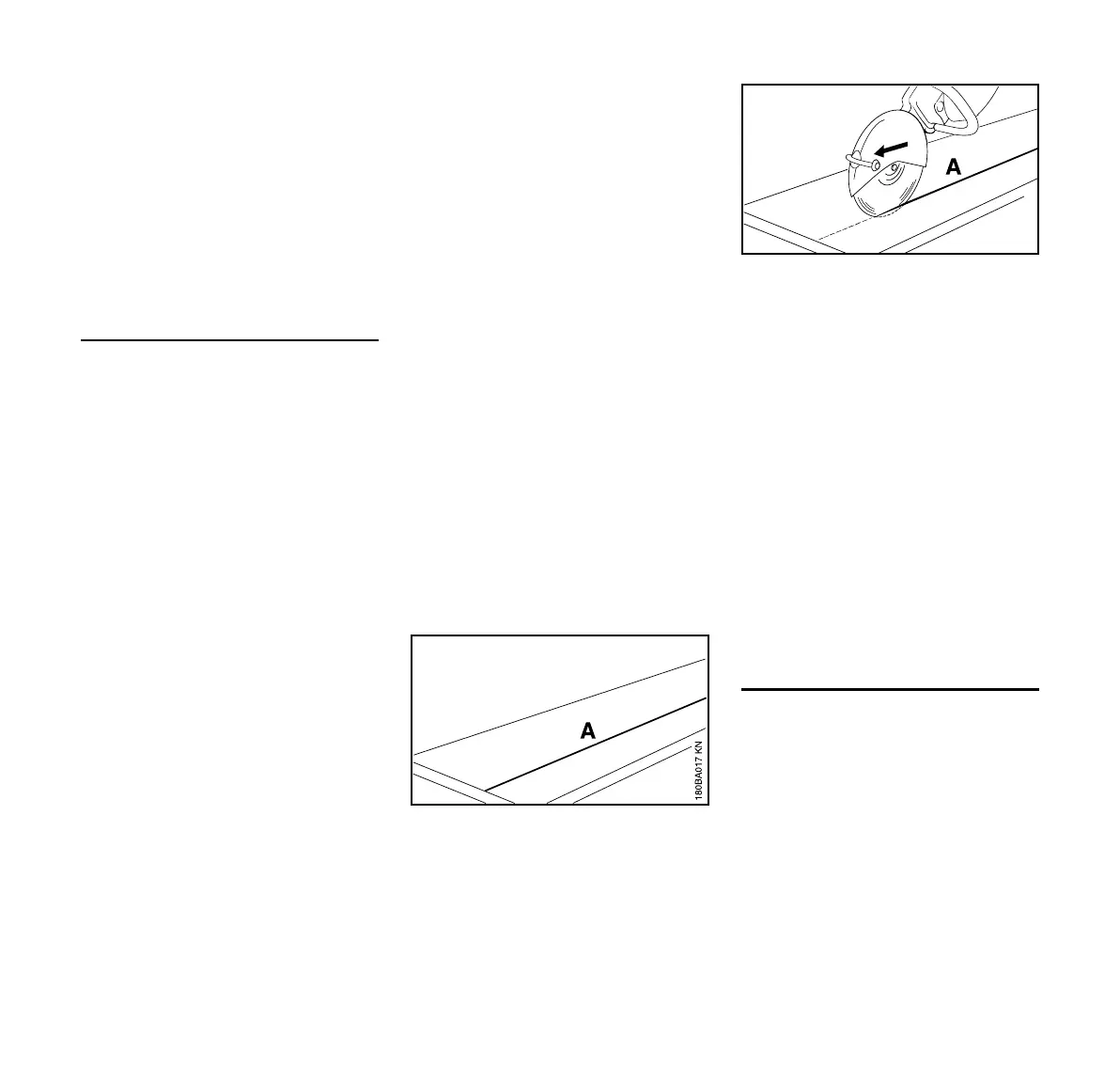

Cutting in several passes

N Mark cutting line (A).

N Work along the cutting line. If

corrections are necessary, always

lift the machine and reposition the

cutting wheel, taking care to ensure

that it is not wedged, tilted, twisted

or side loaded. Attempting to

change the position or direction of a

cut while the wheel is in the cut can

bind the wheel. This can lead to

kickback, other reactive forces or a

shattered composite cutting wheel,

which could result in severe or fatal

personal injury.The cutting depth

per pass should not exceed 2“ to

2 1/2“ (5 to 6 cm). Thicker material

must be cut in several passes. The

maximum cutting depth for abrasive

cutting wheels with a 14" diameter is

4.9 in. (125 mm).

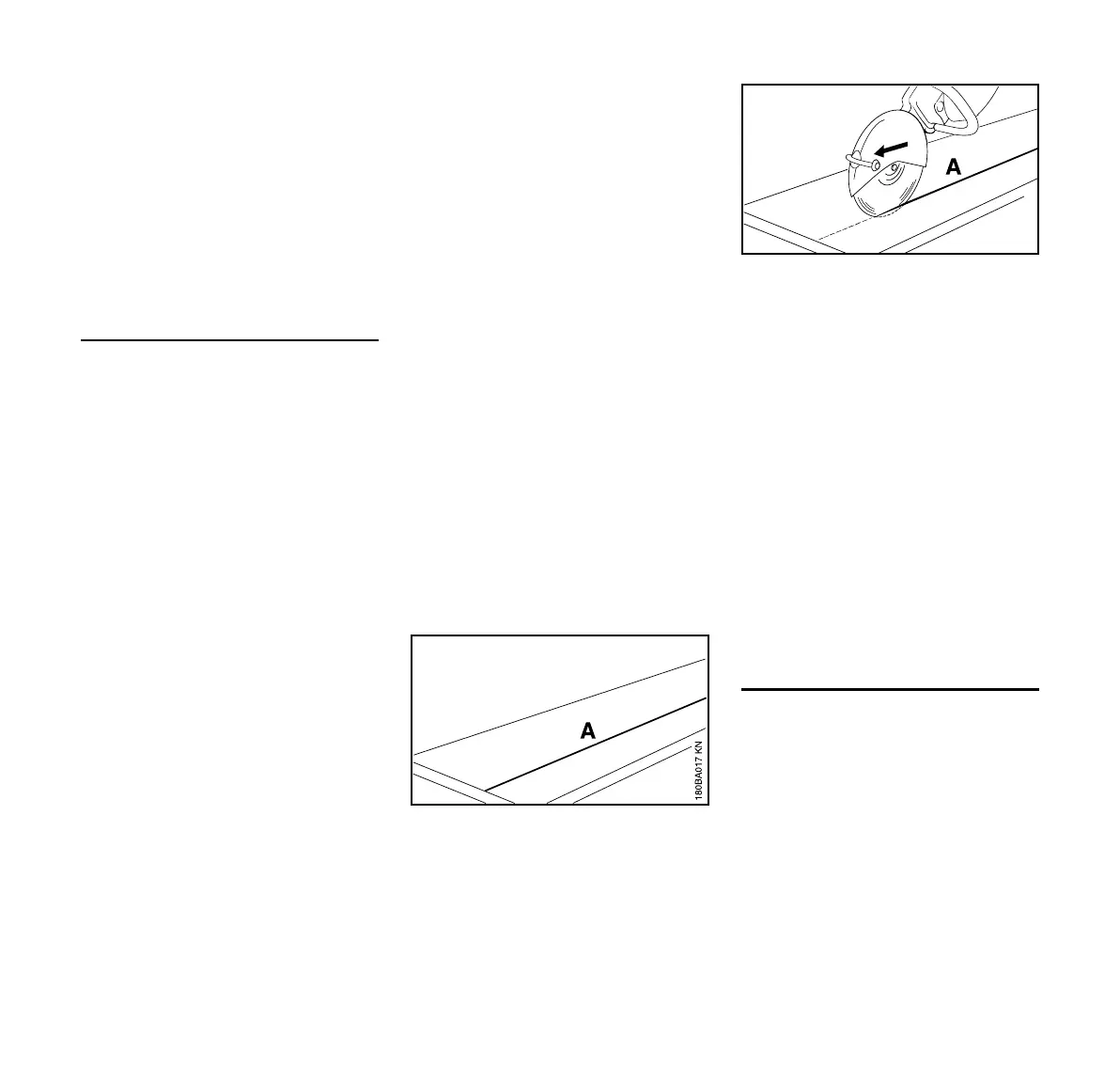

Cutting slabs

N Secure the slab (e. g. on a non-slip

surface, sandbed) and mark the

cutting line.

180BA027 AM

Loading...

Loading...