Built-In

Built-In

(600-

(600-

2

2

)

)

Series

Series

Electronic Control System

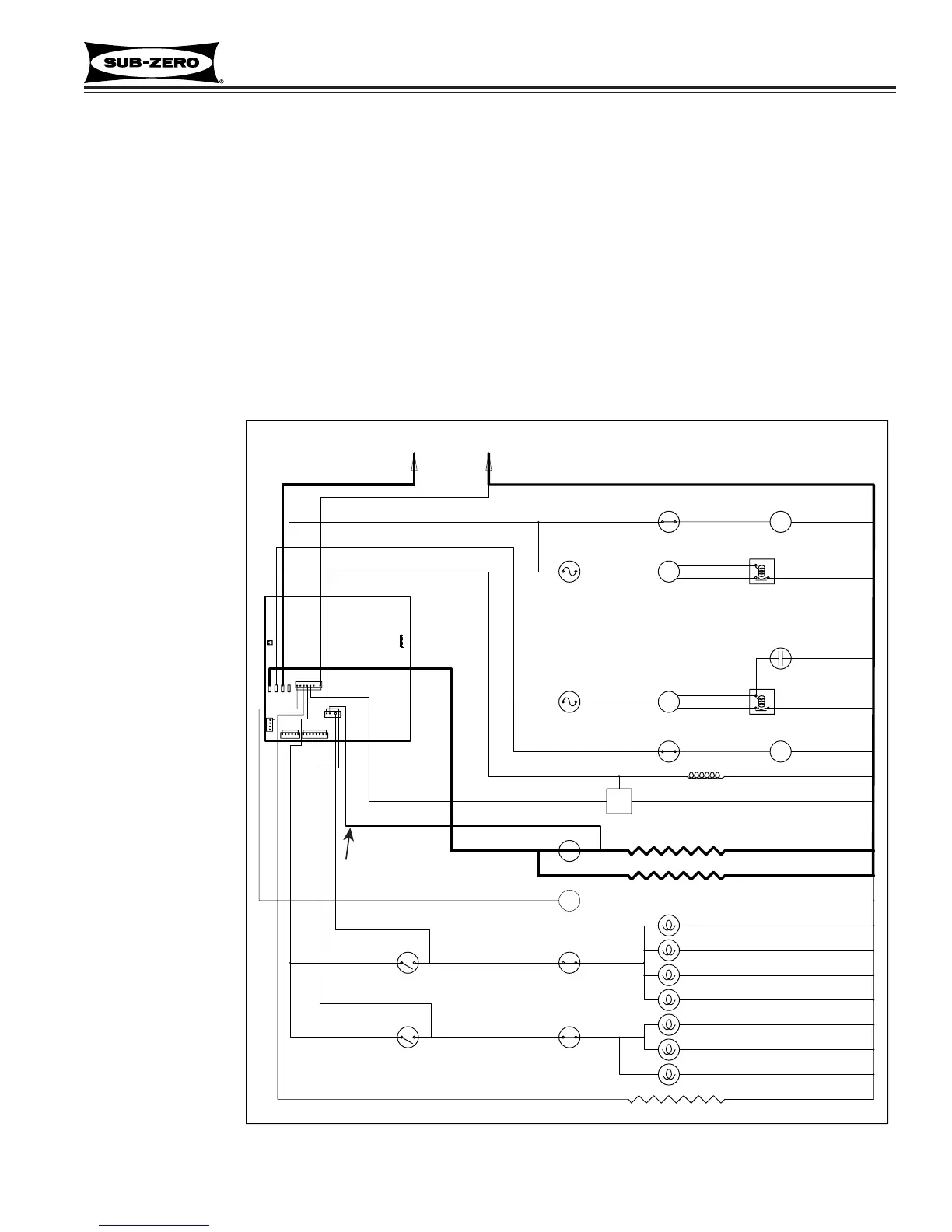

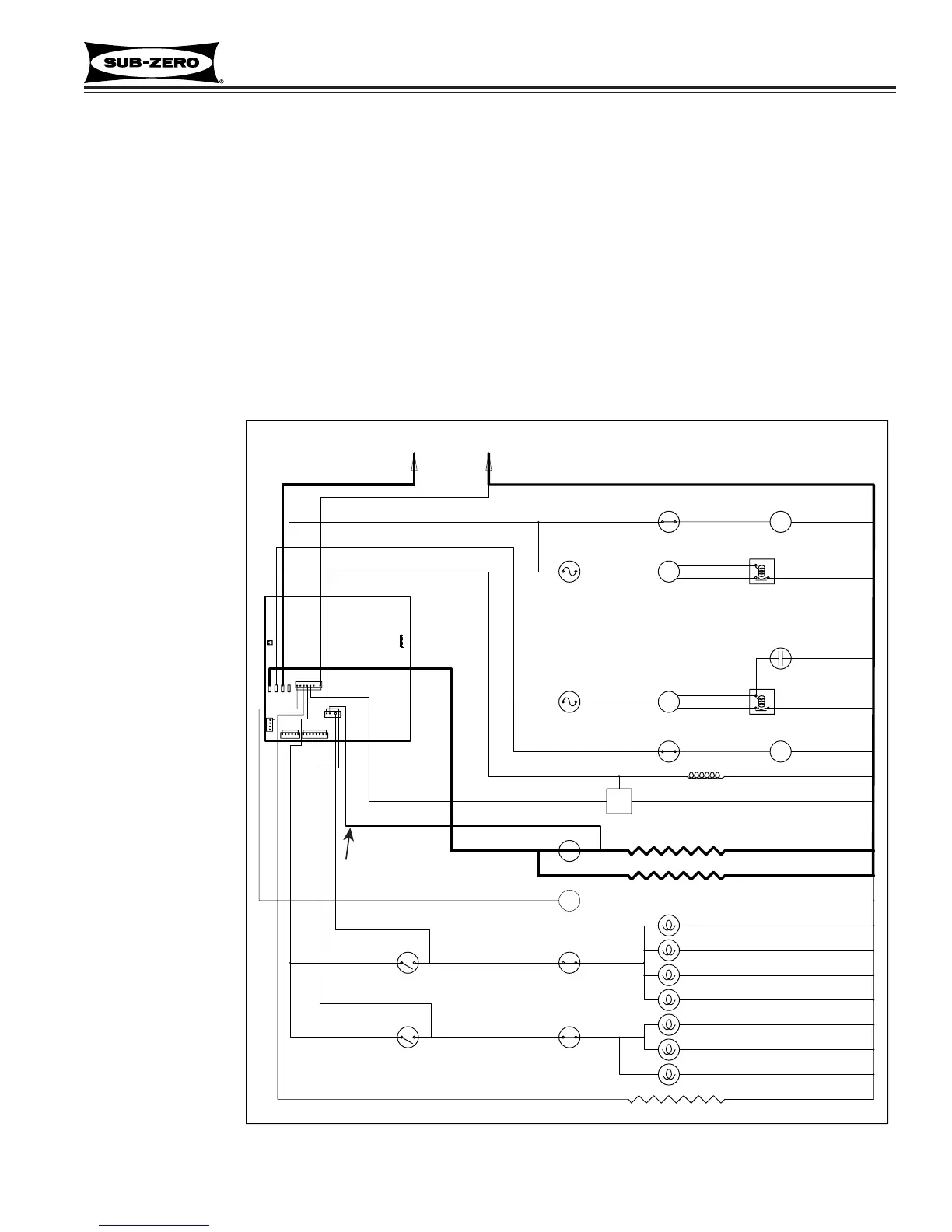

Monitor and Control “Adaptive Defrost” of Freezer Evaporator

Initially, the freezer compressor cycle-runs 12 hours. The control board defrost relay is then closed, supplying power

to the defrost, drain tube and fill tube heaters. The compressor, condenser fan and evaporator fan are switched off.

With “Adaptive Defrost”, the length of time the defrost heater stays on to open the defrost terminator bimetal

(55°F/13°C), is observed by the microprocessor via the grey w/white stripe wire to J4. This length of time is used to

calculate the number of hours before the next defrost (defrost interval). If the heater then stays on for a shorter time

period, the microprocessor increases the next defrost interval. If the heater then stays on for a longer time period,

the microprocessor decreases the next defrost interval. (See Figure 3-16) This is an ongoing process whereby the

defrost time and the defrost interval will vary by unit use.

NOTE: A 5 minute time delay/dwell follows all defrosts, during which the drain tube and fill tube heaters remains

energized. At the end of the 5 minute dwell, the compressor, evaporator fan and condenser fan are energized, and

the drain tube heater is switched off.

NOTE: Minimum defrost interval = 6 hours of compressor run time; Maximum defrost interval = 80 hours of com-

pressor run time; Maximum defrost duration = 20 minutes, plus 5 minute dwell.

NOTE: If the defrost

sensing line is open,

defrost operation

defaults to 25 minute

defrost time / 6 hour

build time, and Error

Code 22 is logged. If

the evaporator ther-

mistor detects an

under-heat or over-

heat situation at the

same time, Error

Codes 20 or 23 is

logged, respectively.

NOTE: During

defrost, the displayed

temperature is

locked.

Figure 3-16. Signal Trace Schematic of Freezer Adaptive Defrost

defrost sense line.

until 5 minutes after defrost.

code will be logged.

Loading...

Loading...