Section 8

MAINTENANCE

49

8.1 GENERAL

As you proceed in reading this section, it will be

easy to see that the Maintenance Program for the

air compressor is quite minimal. The use of the

service indicators provided for the fluid filter, air fil-

ter and fluid separator, will alert you when service

maintenance is required. See instructions for each

item in Section 8.7, Parts Replacement and

Adjustment procedures.

8.2 DAILY OPERATION

Prior to starting the compressor, it is necessary to

check the fluid level in the sump. Should the level

be low, simply add the necessary amount. If the

addition of fluid becomes too frequent, a simple

problem has developed which is causing this

excessive loss. See the Troubleshooting Section

under Excessive Fluid Consumption for a probable

cause and remedy.

After a routine start has been made, observe the

instrument panel gauges to be sure they monitor

the correct readings for their particular phase of

operation. After the compressor has warmed up, it

is recommended that a general check on the over-

all compressor and instrument panel be made to

assure that the compressor is running properly.

8.3 MAINTENANCE AFTER INITIAL 50 HOURS OF

OPERATION

After the initial 50 hours of operation, a few mainte-

nance requirements are needed to clean the sys-

tem of any foreign materials. Perform the following

maintenance operations to prevent unnecessary

problems.

1. Clean the return line strainer.

2. Clean the return line orifice.

8.4 MAINTENANCE AFTER FIRST 1000 HOURS

After 1000 hours of operation, it will be necessary

to perform the following:

1. Clean the return line strainer.

2. Replace the fluid filter element and gasket.

8.5 MOTOR BEARINGS

Grease motor per manufacturer’s recommenda-

tions.

8.6 FLUID MAINTENANCE

Drain the sump and change the compressor fluid

per recommendations in Section 3, Specifications.

Standard models are filled with Sullube. Sullube

should be changed under the following conditions,

whichever occur first:

1. Every 8000 hours.

2. Once a year.

3. As indicated by fluid analysis.

A fluid sample at every 1000 hours is recommend-

ed. For a free Sullube analysis, send fluid to:

Dow Chemical

Lubricant Technology Center

Building B-1605

Freeport, TX 77541

To facilitate this, a sample bottle is included with the

compressor.

8.7 PARTS REPLACEMENT AND ADJUSTMENT

PROCEDURES

Please familiarize yourself with the safety guide-

lines offered in Section 1, Safety of this manual

before attempting any maintenance on the pack-

age.

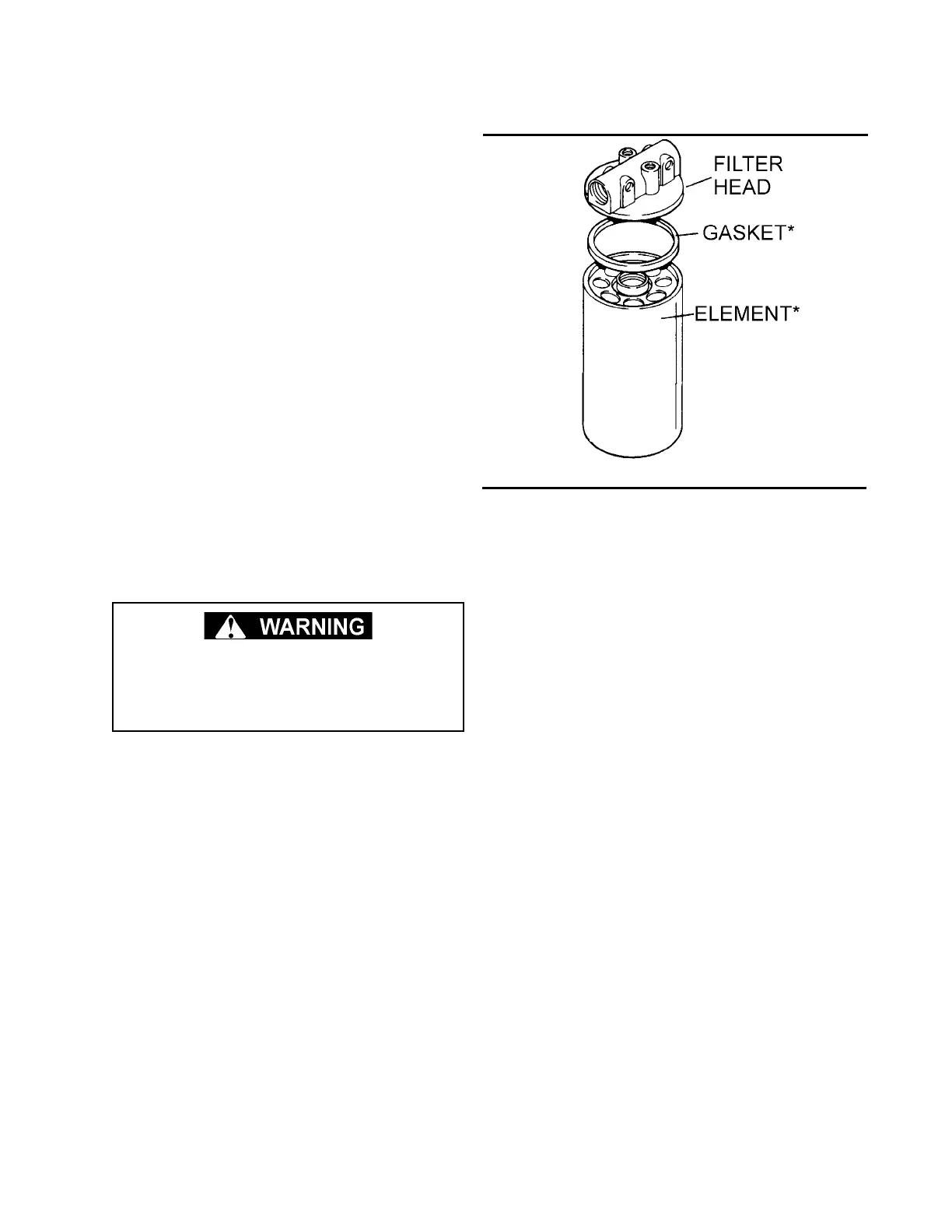

FLUID FILTER MAINTENANCE

Refer to Figure 8-1. Replace your fluid filter element

and the gasket under any of the following condi-

tions, whichever occurs first:

1. As indicated by the maintenance indicator.

2. Every 1000 hours of operation.

Figure 8-1 Fluid Filter (P/N 02250054-605)

*Repair Kit P/N 250025-526

DO NOT remove caps, plugs, and/or other com-

ponents when compressor is running or pressur-

ized.

Stop compressor and relieve all internal pressure

before doing so.

Loading...

Loading...