F Series Manual

15

2.1.3 Installing / Removing a module

WARNING: For safety reasons, always make sure no tool is installed in the

module. Only install a module when the flatbed is switched off or after clicking

‘Change Tool’ in Axis Control.

2.1.3.1 Installing a module

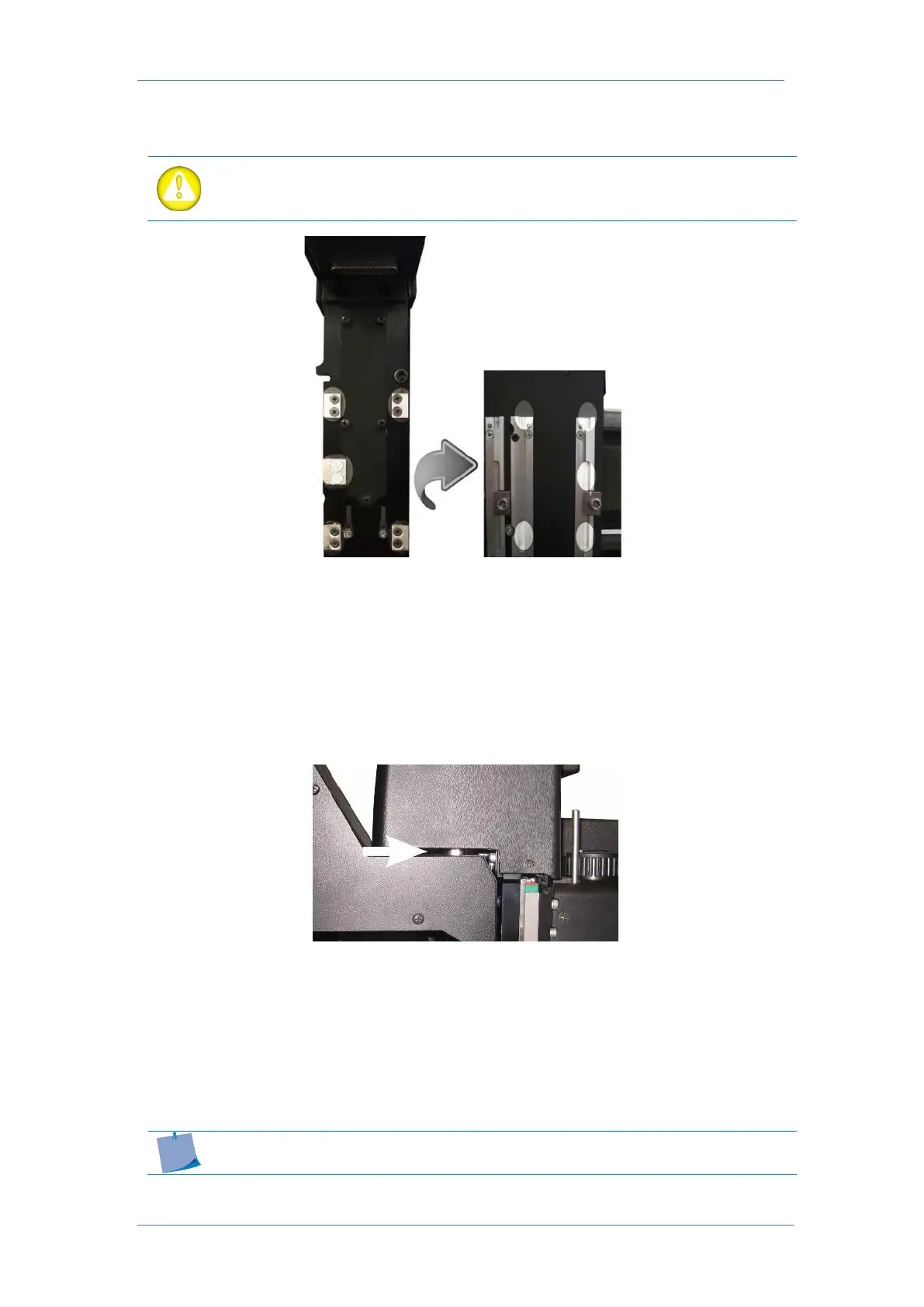

In order to install a module, line up the 5 highlighted areas and slide the module down. The

module glides into the carriage in a dovetail guiding. Do not use excessive force, otherwise,

the connector can be damaged. Recheck the alignment when in doubt. The module must be

pushed down approximately 15 mm (0,6”) and is secured with one screw on the right side.

Before securing the module check if the connector of the module is completely seated in the

connector of the carriage.

2.1.3.2 Removing a module

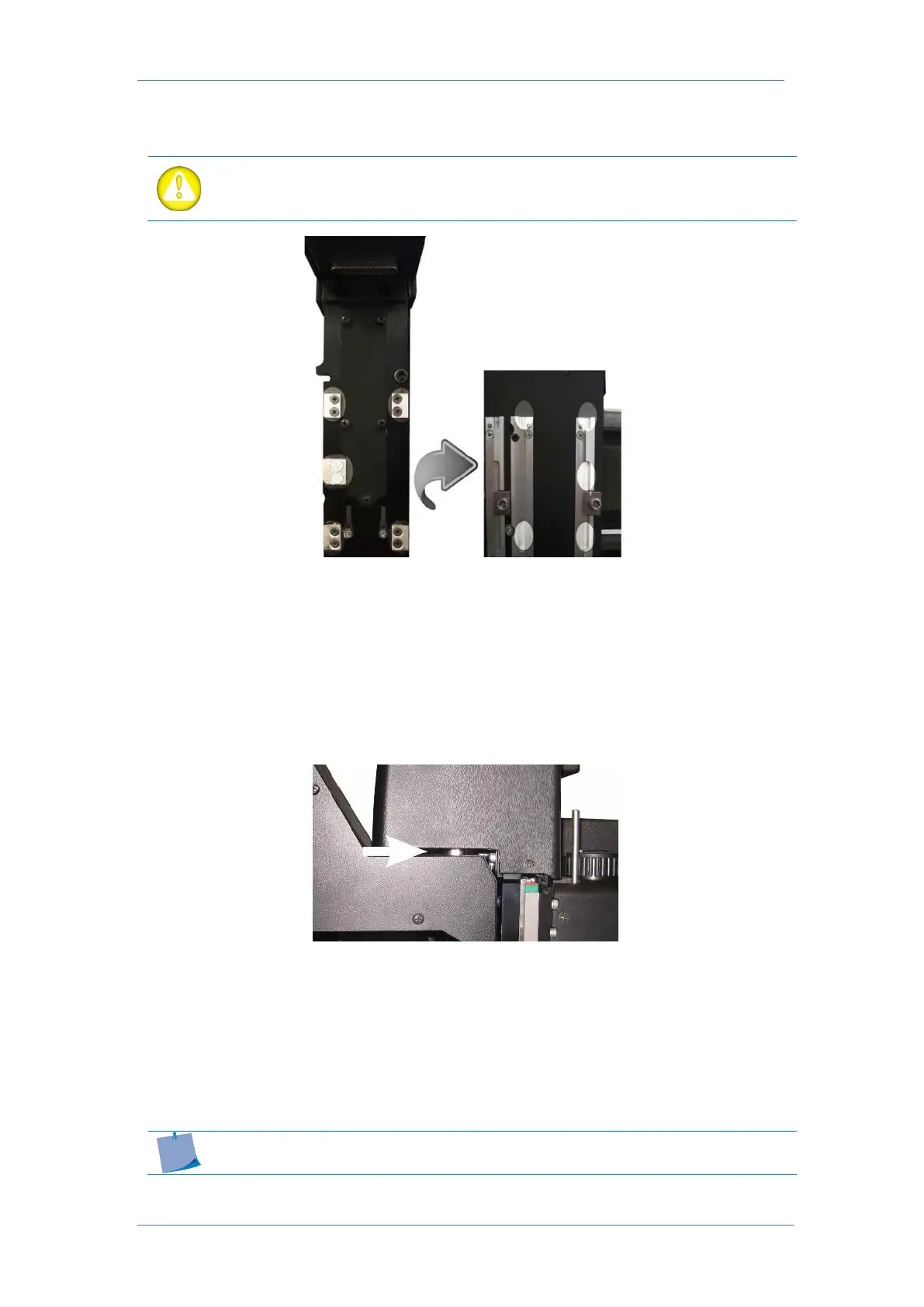

To remove a module, loosen the screw at the right side of the module for about 1 turn

counterclockwise with the hex screwdriver. Put this screwdriver in the hole under the module

on the right side. Now gently lift the module with the screwdriver 3 to 4 mm (0.12 to 0,16”).

Guide the module manually for an extra 10 mm (0,4”) and remove it from the carriage. The

drag module does not have such a hole to lift the module, so just lift it manually.

It is recommended to remove any unused modules. Leaving unused

modules on the carriage can lead to poorer cutting quality.

Loading...

Loading...