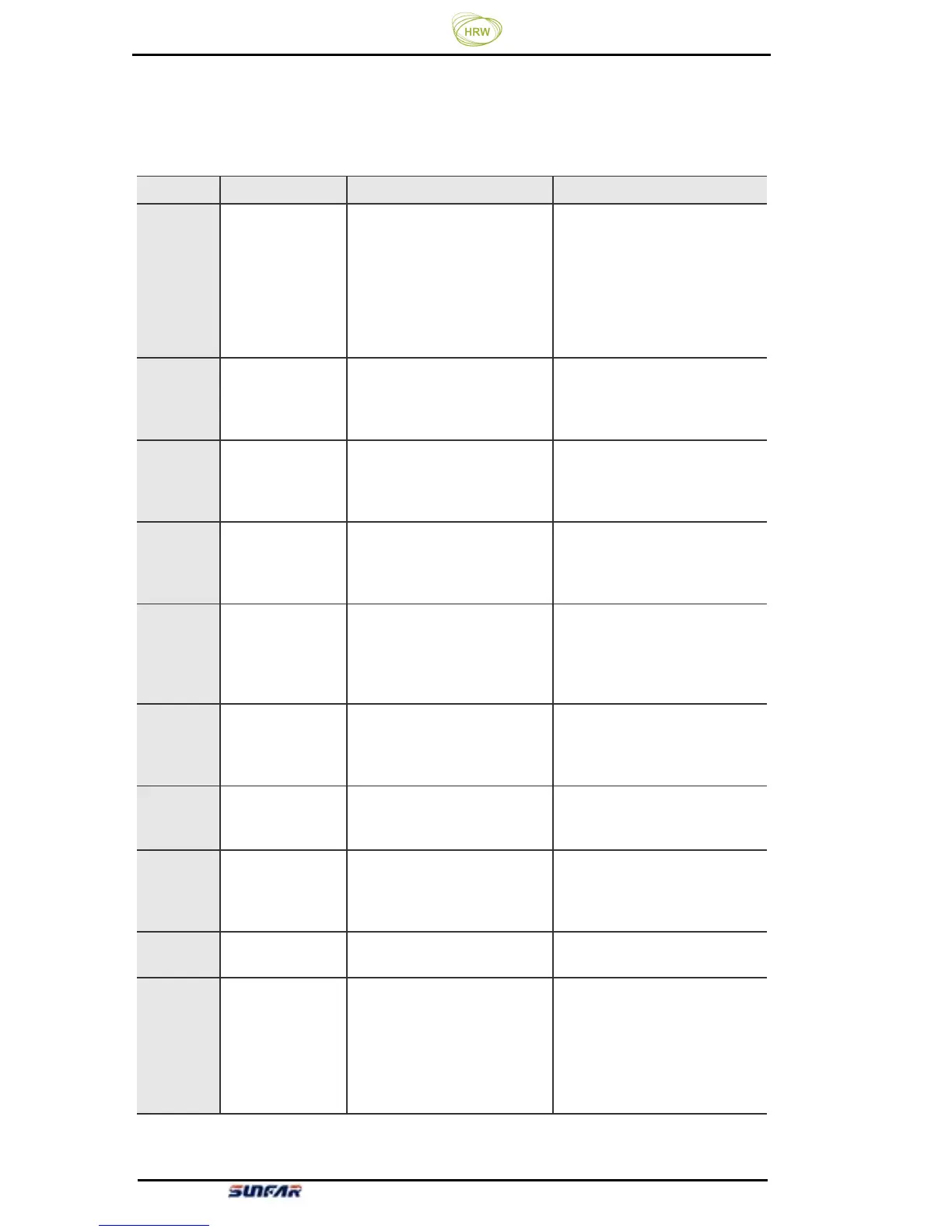

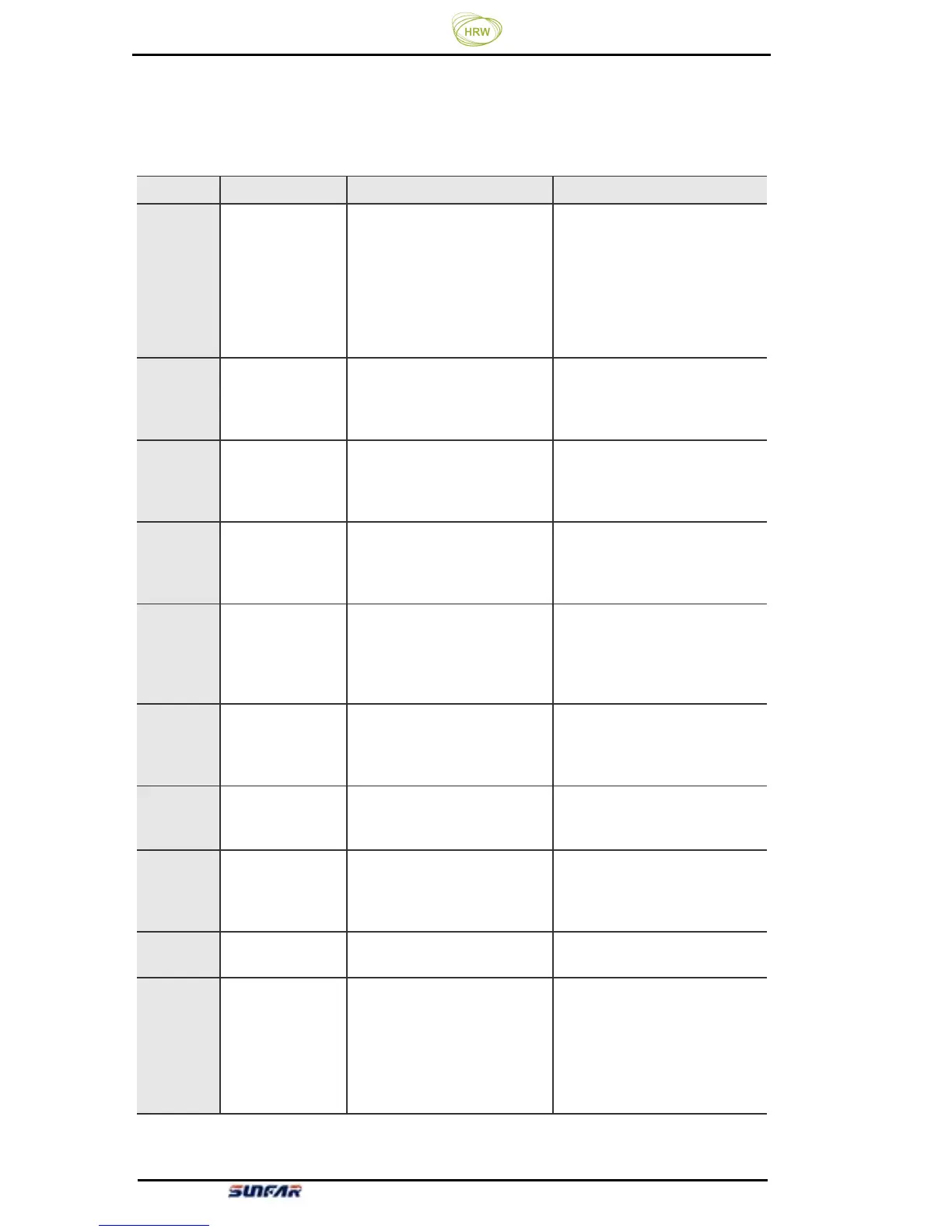

66 Fault Diagnosis And Countermeasures

E500 Series Universal Low-Power Inverter

7 Fault Diagnosis And Countermeasures

7.1 Protection function and countermeasures

Fault Code Fault Descriptio

Possible Reasons Solutions

Fu.01

Over current

occurs in inverter

acceleration

running process

1. The acceleration time is

too short.

2. Start the rotating motor

directly.

3. The torque boost is preset

as too large.

4. The network voltage is

too low.

1. Extend acceleration time.

2. Restart the motor after stop

3. Reduce voltage of torque

boost.

4. Check the network voltage

and reduce power.

Fu.02

Over current

occurs in inverter

deceleration

running process

The acceleration time is too

short.

Increase the acceleration time

Fu.03

Over current

occurs in inverter

running

or stop condition

1. Load changes suddenly

2. The network voltage is

too low.

1. Reduce the load

fluctuation.

2. Check the power voltage.

Fu.04

Overvoltage

occurs in inverter

acceleration

running process

1.

The input voltage is too

high.

2. Put the power on and

off frequently.

1. Check the power.

2. Lower the setting of

acceleration torque level.

Fu.05

Overvoltage

occurs in inverter

deceleration

running process

1.

The acceleration time is

too short.

2.

The input voltage is

abnormal.

1. Extend the acceleration

time.

2. Check the power voltage.

3. Install braking resistor or

reselect braking resistor.

Fu.06

Overvoltage

occurs in inverter

running process

1. The power voltage is

abnormal.

2. There is energy feedback

load.

1. Check the power voltage.

2. Install the braking unit and

braking resistor or reselect

raking resistor.

Fu.07

Overvoltage

occurs in inverter

stop condition

The power voltage is

abnormal.

Check the power voltage.

Fu.08

Under-voltage

occurs in inverter

running process

1. The power voltage is

abnormal.

2. There is starting operation

of heavy load in network.

1. Check the power voltage.

2. Supply power separately.

Fu.09

~Fu.11

Reserve

Fu.12 Inverter overload

1. The load is too large.

2. The acceleration time is

too short.

3.The torque boost is too

high.

4. The network voltage is

too low.

1. Reduce load or change a

larger capacity inverter.

2. Extend the acceleration

time.

3. Reduce the voltage of

torque boost.

4. Check the network voltage.

Loading...

Loading...