12

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Unit Being Secured by Its Nailing

Flanges to the Framing

Installation and Operation Instructions

900300-00, 02/2015

Innovative Hearth Products

Superior

TM

DRT35 See Through and Peninsula Direct Vent Gas Fireplace

Figure 11

REMOVE

CARDBOARD

BEFORE USING

Pressure Relief

Plates

Remove Cardboard Before

Using Appliance

REMOVE

CARDBOARD

BEFORE USING

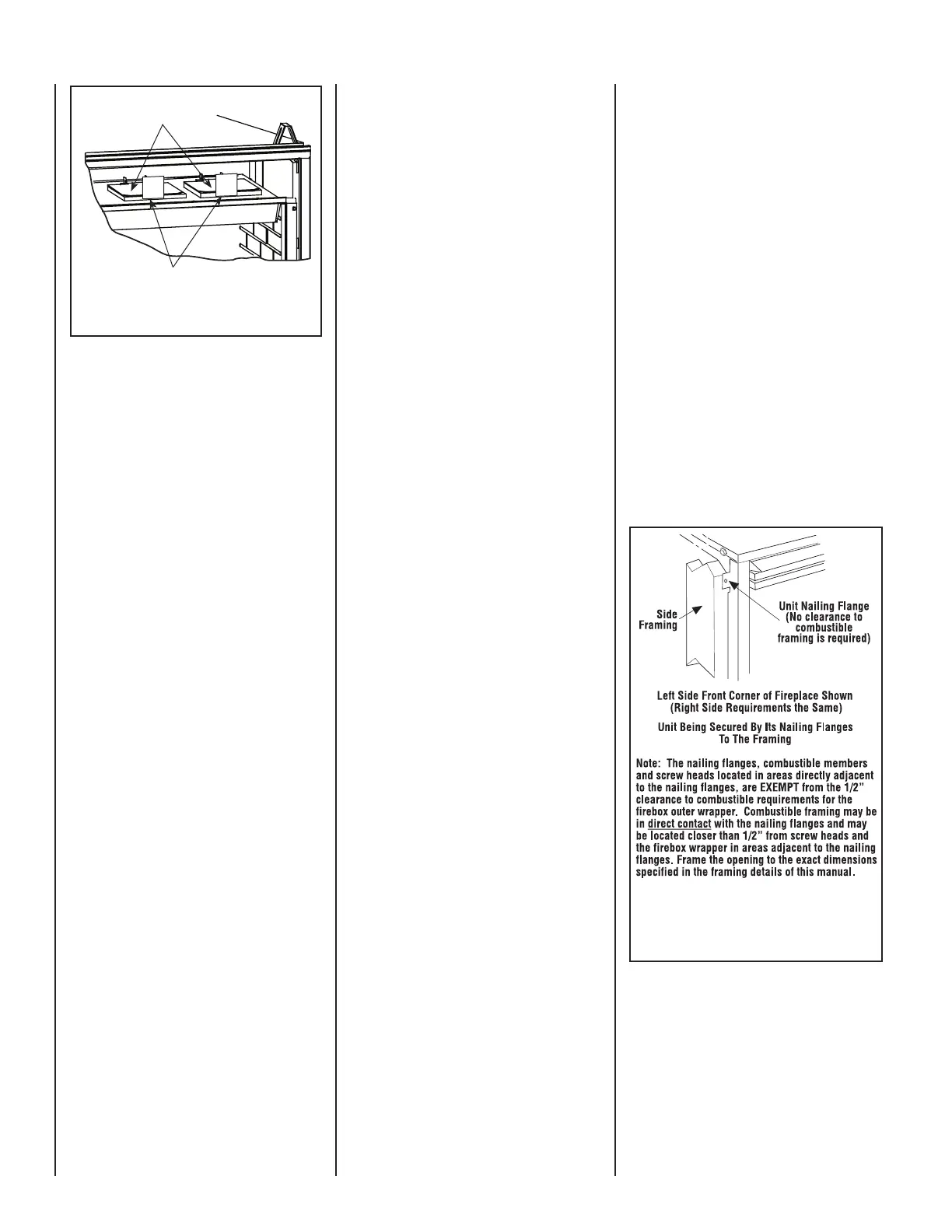

Figure 12 - Nailing Flanges

Step 1. FRAMING

Frame these appliances as illustrated in Figures

13 and 14 on Pages 13 and 14. All framing

details must allow for a minimum clearance

to combustible framing members as shown

in Table 5 on Page 8.

If the appliance is to be elevated above floor level,

a solid continuous platform must be constructed

below the appliance.

Headers may be in direct contact with the appli-

ance top spacers when they are bent up vertically

maintaining the 3" clearance to the fireplace top,

but must not be supported by them or notched

to fit around them. All construction above the

appliance must be self-supporting. DO NOT use

the appliance for structural support.

The fireplace should be secured to the side

framing members using the unit's nailing

flanges - one top and bottom on each side of

the fireplace front. See Figure 12. Use 8d nails

or their equivalent.

TYPICAL INSTALLATION SEQUENCE

The typical sequence of installation is outlined

below. However, each installation is unique

and may result in variations to the steps

described.

See the page numbers references in the follow-

ing steps for detailed procedures.

Step 1. (Page 12) Construct the appliance

framing. Position the appliance within the

framing and secure with nailing brackets. Bend

up the appropriate header spacing guides for

the drywall/finish material thickness to be used

(refer to Figure 62, page 35). Bend up the

outer pair for 1/2" materials and the inner pair

for 5/8" materials. Bend out the appropriate

nailing flanges for the drywall/finish material

to be used. Nailing flanges are provided for

flush framing, 1/2 inch and 5/8 inch framing

depths (see Figure 12).

Step 2. (Page 15) Route gas supply line to

appliance location.

Step 3. Preparing the appliance vent collar

(Page 15).

Step 4. (Page 16) Install the vent system and

exterior termination.

Step 5. (Page 28) Field Wiring

a. Millivolt Appliances – Install the operating

control switch (not factory provided) and bring

in electrical service line for forced air-circulating

blower (optional equipment).

b. Electronic Appliances – Field wire and install

operating control switch.

Step 6. (Page 29) Install blower kit (optional

equipment).

Step 7. (Page 29) Make connection to gas

supply.

Step 8. (Page 30) Verifying appliance operation.

Step 9. (Page 31) Install the logs, decorative

volcanic stone and glowing embers.

Step 10. (Page 35) Install glass door assembly.

Step 11. (Page 35) Adjust burner to ensure

proper flame appearance.

Step 12. (Page 37) Install front face assembly

with barrier. Install the hoods.

Step 13. (Page 38) Attach Safety in Operation

Warnings.

Before proceeding it may be helpful to remove

the log set form the firebox and remove the

embers and volcanic stone from the control

compartment. Refer to the following steps:

1. Remove the front face assembly, hood

and glass enclosure panel (see Removing and

Installing Glass Enclosure Panels on Page 35).

2. Remove log set box from firebox. Next,

remove embers and volcanic stone from con-

trol compartment. Handle logs carefully to

prevent breakage.

Loading...

Loading...