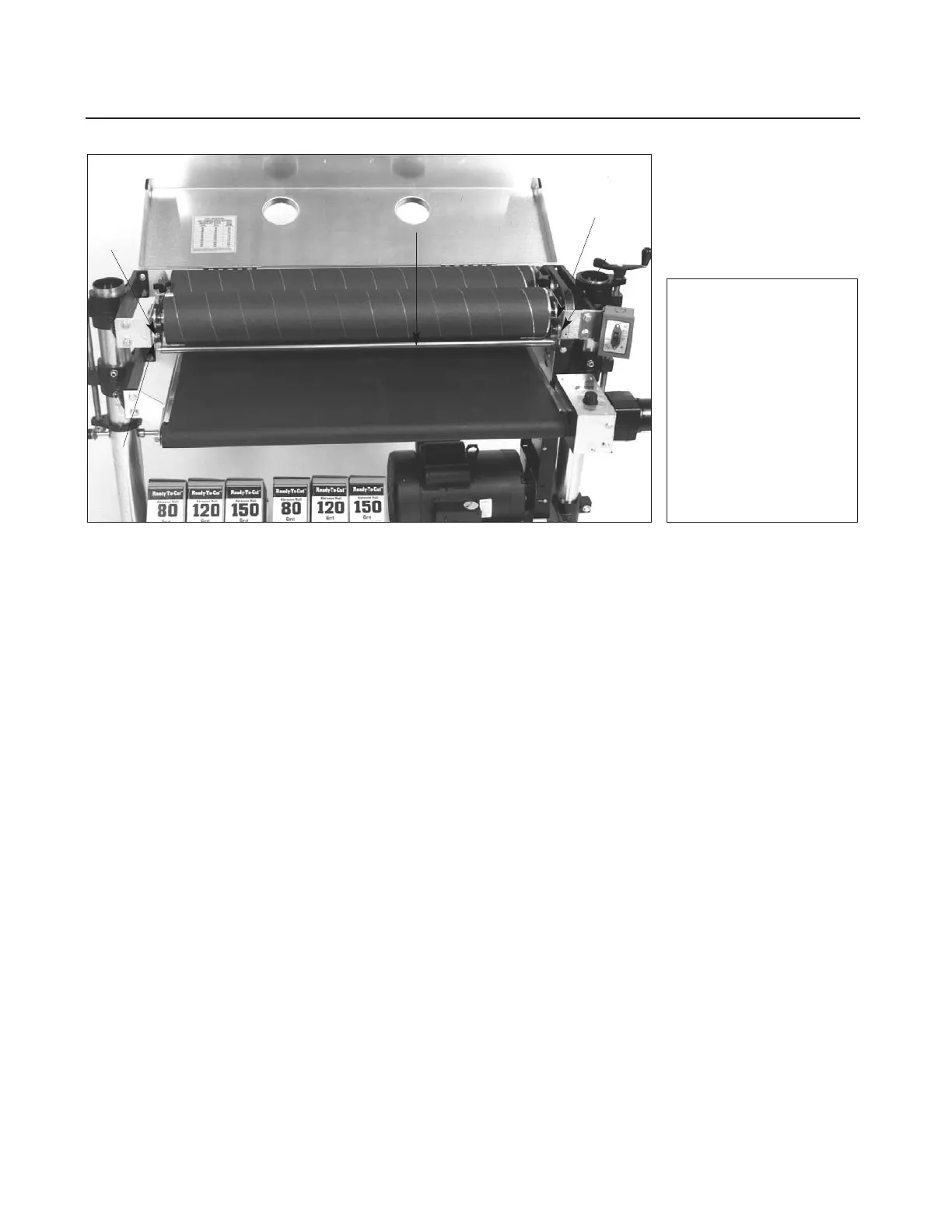

Fig. 28. Tension roller

adjustment.

1. Tension Roller

Suspension Bolts.

2. Tension Roller

3.

Spring Retaining

Screws.

28 SUPERMAX OWNER’S MANUAL

shaft collar below the bracket, then loosen the

screw. Making sure the adjustment knob is tightly

seated on top of the bracket, raise the shaft collar

up against the bracket from below and tighten the

set screw. Note: The nut of the rear bolt on the

rear (secondary) drum bearing bracket should be

backed off a quarter-turn from being fully tight-

ened. This allows the lock washer under the rear

bolt on the rear bracket to be depressed slightly,

but not completely. After alignment is completed,

lower the motor mount to re-establish V-belt ten-

sion. Tighten two screws in belt guard.

ADJUSTING TENSION ROLLERS

With the sanding drums properly aligned, raise the

table to the bottom of the sanding drums. Loosen

all four tension roller suspension bolts (see 1, Fig.

28). Lower the table by one full turn of the height

adjustment handle. At this position the tension

roller assembly should be resting on the table with

the drums suspended slightly above the table.

Then retighten the tension roller suspension bolts.

Note: Too much tension roller pressure can cause

snipe marks which are identified as a visible line

running across the width of the board approxi-

mately 2 1/4" from the end of the board. If a snipe

mark occurs on the trailing end of the board,

adjust the infeed tension roller. Tension roller pres-

sure can be adjusted two ways, either by loosening

the tension roller spring retaining screws (see 3,

Fig. 28) or by raising the height of the tension

rollers. To adjust the tension rollers to eliminate

snipe marks, use this two-step procedure:

Step 1. With the sanding drums properly aligned,

loosen all four tension roller suspension bolts.

Raise the table to the bottom of the sanding

drum(s). The tension rollers should be resting

firmly on the conveyor bed. Tighten only the two

rear (outfeed) tension roller suspension bolts.

Step 2. Lower the conveyor table by one full turn

of the height adjustment handle. At this point,

press down on the front (infeed) tension roller so

it is resting on the table. Now tighten the front

(infeed) tension roller suspension bolts. If there

still is a snipe mark left on pieces being sanded,

repeat Step 1 and Step 2, but in Step 2 lower the

conveyor bed a half turn instead of a full turn.

Warning: Improperly adjusted tension rollers (i.e.,

those set too high, rendering them non-functional)

could allow kick-back/slippage of pieces being

sanded.

Loading...

Loading...