MOUNTING

BOLT

SERVICING YOUR SUPERMAX

31

4. Align the V-belt pulleys with the pulley on the

motor and then tighten the set screws in the V-belt

pulleys. Spin the drums by hand to make sure the

pulleys are in proper alignment.

5. Check the alignment of the front drum to the

conveyor table. If they are not parallel, level the

front and then the rear drum (see pages 7 and 8)

before proceeding further.

6. Readjust the tension of the V-belt by sliding the

motor down and then tightening the pinch bolt in

the motor support casting. Make sure all pulleys are

aligned and all bolts tight before using the sander.

7. Reinstall the outer belt guard using the two

5/16" x 1/2" hex head bolts. Reinstall the lower

belt guard using the two 10-32 screws and the

middle, inner guard using two 10-32 screws.

REPLACING CONVEYOR BELTS

To replace the conveyor belt, the conveyor assem-

bly must be removed from the machine. Lower the

conveyor table to its lowest position with the

height adjustment handle. Remove the bottom

cover from control box, rotate shaft to access set

screws in shaft coupler. Important: Disconnect

power to sander. Loosen one set screw. Remove

the four 5/16" bolts holding the conveyor motor

control box base bracket (Fig. 45). Remove con-

veyor motor control box and place on dust cover.

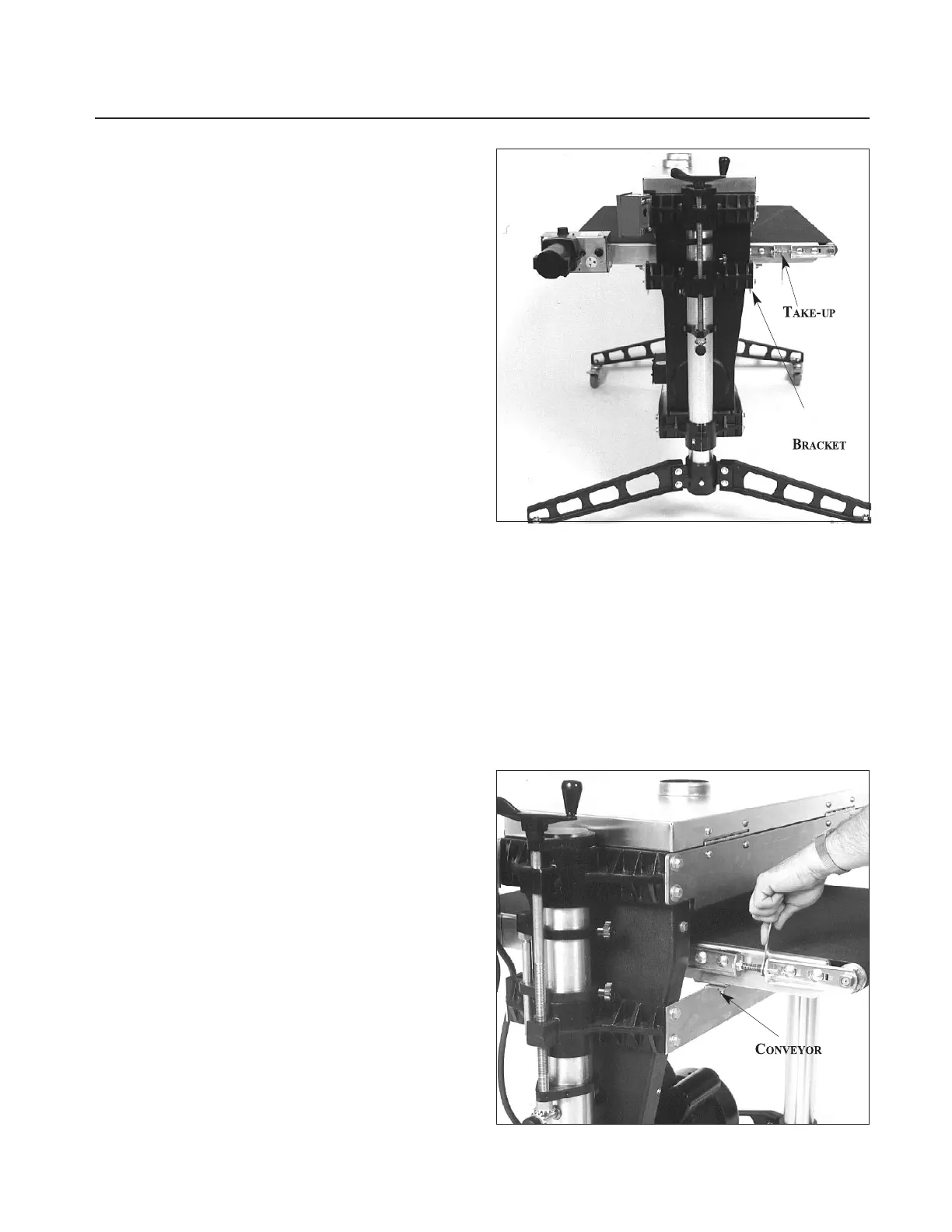

Loosen the conveyor take-up screws (Fig. 35 and

Fig. 36) to relieve belt tension and slide the driven

roller fully inward. Remove the four bolts that

attach the conveyor assembly to the table mount

brackets (see Fig. 36). Lift the conveyor and

remove it from the machine by sliding the convey-

or out toward the front of the machine. Avoid

tearing the belt on any edges underneath the con-

veyor bed during removal. Reverse the procedure

for re-installation.

Note: If the conveyor belt continually tracks to

one side of the machine, first try reversing the belt

on the conveyor bed. If this doesn’t remedy the

problem, place a level on the conveyor bed to

make sure the conveyor bed is not twisted. If it is

twisted, see page 7 for instructions on squaring up

the bed. If squaring up the bed does not remedy

the problem, proceed with the steps below:

Fig. 35. Conveyor belt replacement.

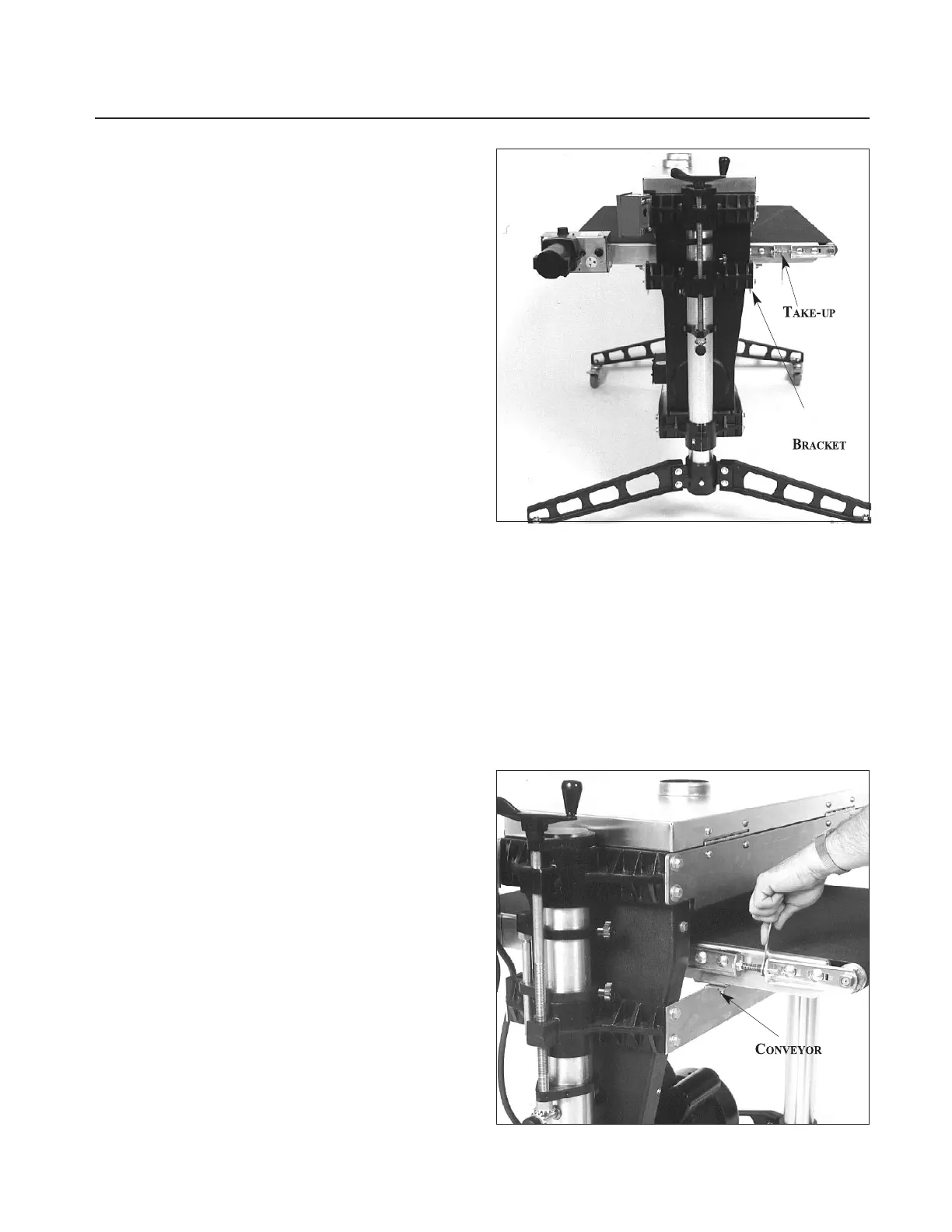

Step 1. Check the conveyor drive and driven roller

to make sure they are parallel to the surface of the

conveyor bed. To do this, first center the conveyor

belt on the bed. Then lay a straight-edge on the

exposed edge of the conveyor table on the left (out-

board) side, extending it over the drive roller, then

driven roller. Note the distance between the drive

roller then driven roller and the straight-edge.

Fig. 36. Tensioning and tracking conveyor belt.

SCREW

TABLE

MOUNT

Loading...

Loading...