ABOUT THE SUPERMAX SYSTEM

5

UNPACKING YOUR SUPERMAX

Your SUPERMAX sander has been shipped com-

pletely assembled from the factory in a cardboard

shroud on a pallet and shrink-wrapped in plastic.

If any damage has occurred as a result of shipment,

notify the transportation company as soon as pos-

sible and ask them to make an immediate inspec-

tion. Ask for a damage or loss report. Also notify

your dealer of any loss or damage during ship-

ment. See enclosed Warranty Statement.

Important: To avoid problems and potential

damage to the machine, please read through the

unpacking instructions below before proceeding to

set up the machine in your shop.

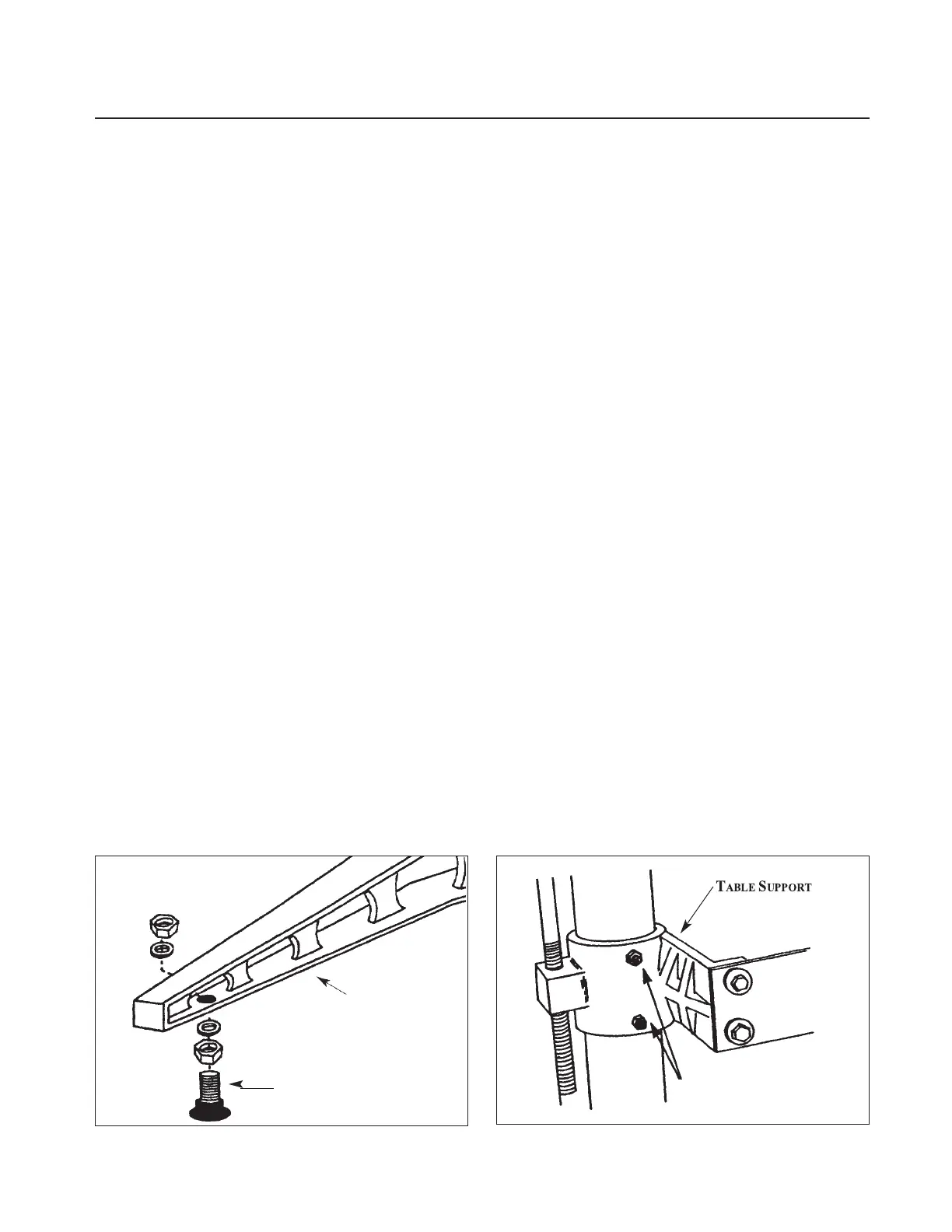

1. Unbolt the machine legs from the shipping

pallet. Install the rubber-based leveling feet or cast-

ers on legs (Fig. 2). The feet and mounting hard-

ware are in the STOP bag packed with your

machine.

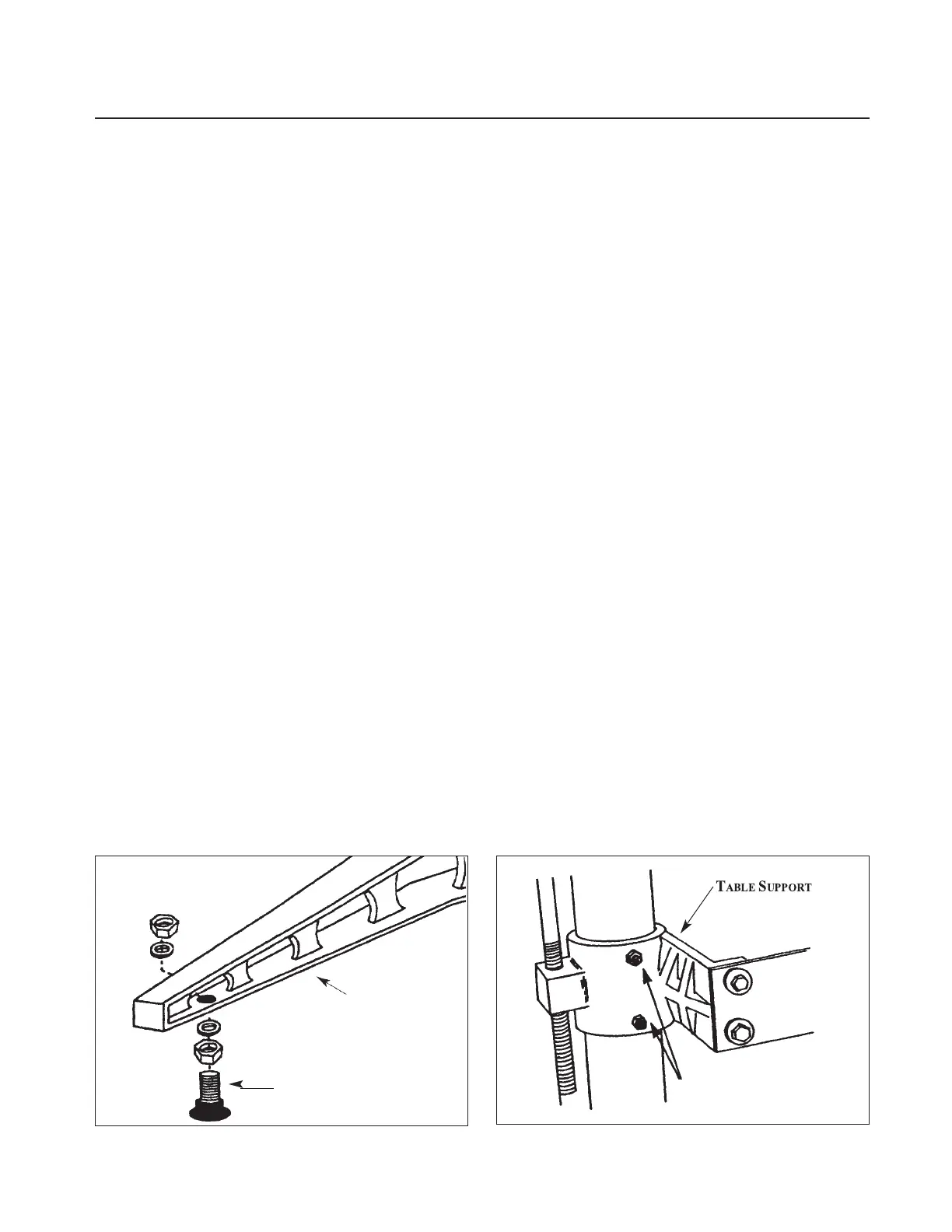

2. Loosen the hex nut and set screws on the table

support castings (Fig. 3). The set screws on the

table support castings have been tightened at the

factory to eliminate free-play between the table

support casting and the column tube during ship-

ment. There are two table support castings on the

SUPERMAX, one each for the right and left column

tubes. Important: These set screws are tightened

for shipping and must be loosened and readjusted

before operating either the height adjustment

mechanism or the conveyor drive.

To properly adjust for operation, loosen each set

screw by first loosening its hex nut with an open-

end wrench and then the set screw with an Allen

wrench. Then retighten each set screw with your

fingers so it only lightly touches the column tube.

Hold each set screw in position with an Allen

wrench and retighten the hex nut. Failure to fol-

low these procedures may result in misalignment

of the drum(s) and/or the conveyor table.

Caution: On the SUPERMAX models do not

loosen the set screws on the upper drum support

castings.

3. Install the power feed gear motor. Rotate the

drive roller on the conveyor system so the flat part

of the shaft is down. If necessary, plug the gear

motor into an appropriate 220V AC outlet to

rotate the motor output shaft coupling so the set

screws face downward. Unplug the gear motor.

Slide the power feed motor assembly onto the

drive roller shaft, aligning the shaft coupling and

four mounting holes. Start the four 5/16" hex

head bolts on the power feed motor mounting

bracket, but do not tighten yet.

Next, tighten the set screws in the coupling on

the drive roller shaft, making sure they are on the

flat of the shaft. Rock the drive roller while tight-

ening the set screws to make sure they are centered

properly on the flat. Install the safety shield on the

bottom of the assembly with two screws. Then

plug in the cord and turn conveyor on full speed.

While it is running, tighten the four 5/16" bolts to

secure the motor assembly in place.

4. If necessary, adjust the tension of the V-belt

between the primary motor and driven pulleys. To

do this, loosen the two screws in lower belt guard

and loosen the pinch bolt located at the back of

the motor support casting. Slide the motor sup-

port casting down the column tube until the V-

belt is taut. Tighten the two screws in lower belt

guard. Retighten the motor support pinch bolt.

Fig. 2. Leveling feet and mounting hardware. Fig. 3. Table support casting and set screws.

EVELING

EET

CASTING

HEX NUT & SET SCREWS

Loading...

Loading...