TAKE-UP

SCREW NUT

HEIGHT

ADJ.

DRUM

TABLE

HEX NUT &

SET SCREW

GEAR

SETTING UP YOUR SUPERMAX 9

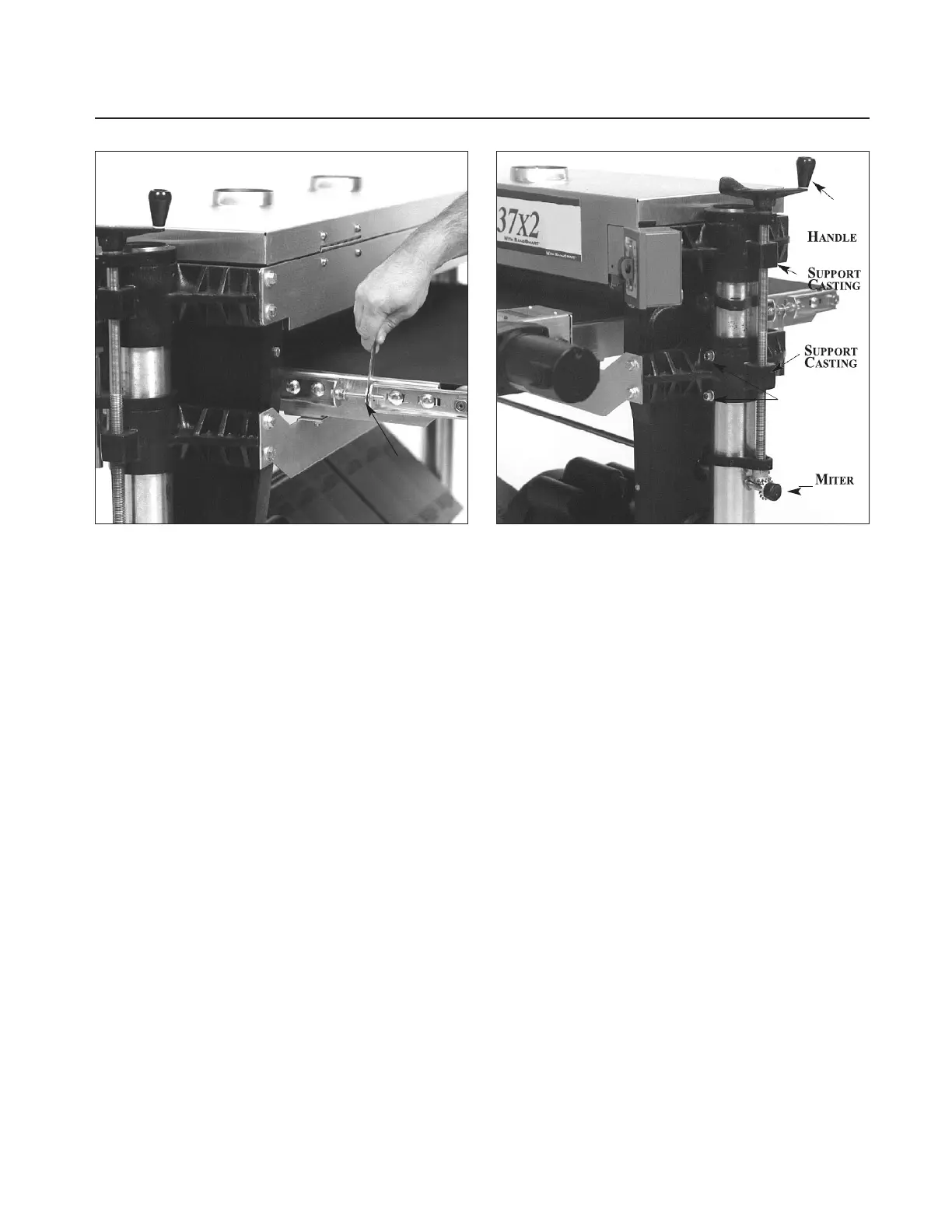

Fig. 10. Adjusting conveyor belt tracking.

result in bent rollers, premature wearing of the

bronze bushings or belt.

Belt Tracking. Belt tracking adjustments are made

while the conveyor belt is running. After the proper

belt tension is obtained (see above), turn the convey-

or unit on and set it at the fastest speed setting.

Watch for a tendency of the conveyor belt to drift to

one side of the conveyor. To adjust the belt tracking,

tighten the take-up screw nut (see Fig. 10) on the

side the belt is drifting toward, and loosen the take-

up screw nut on the opposite side. Adjusting the

take-up screw nuts on either side of the conveyor

allows belt tracking adjustments to be made without

affecting belt tension. NOTE: Adjust the take-up

screw nuts only 1/4 turn at a time. Then allow time

for the belt to react to the adjustments before pro-

ceeding further. Try to avoid over-adjustments.

Make sure wrench is below surface when sanding.

C

HECKING

T

ABLE

H

EIGHT

C

ONTROLS

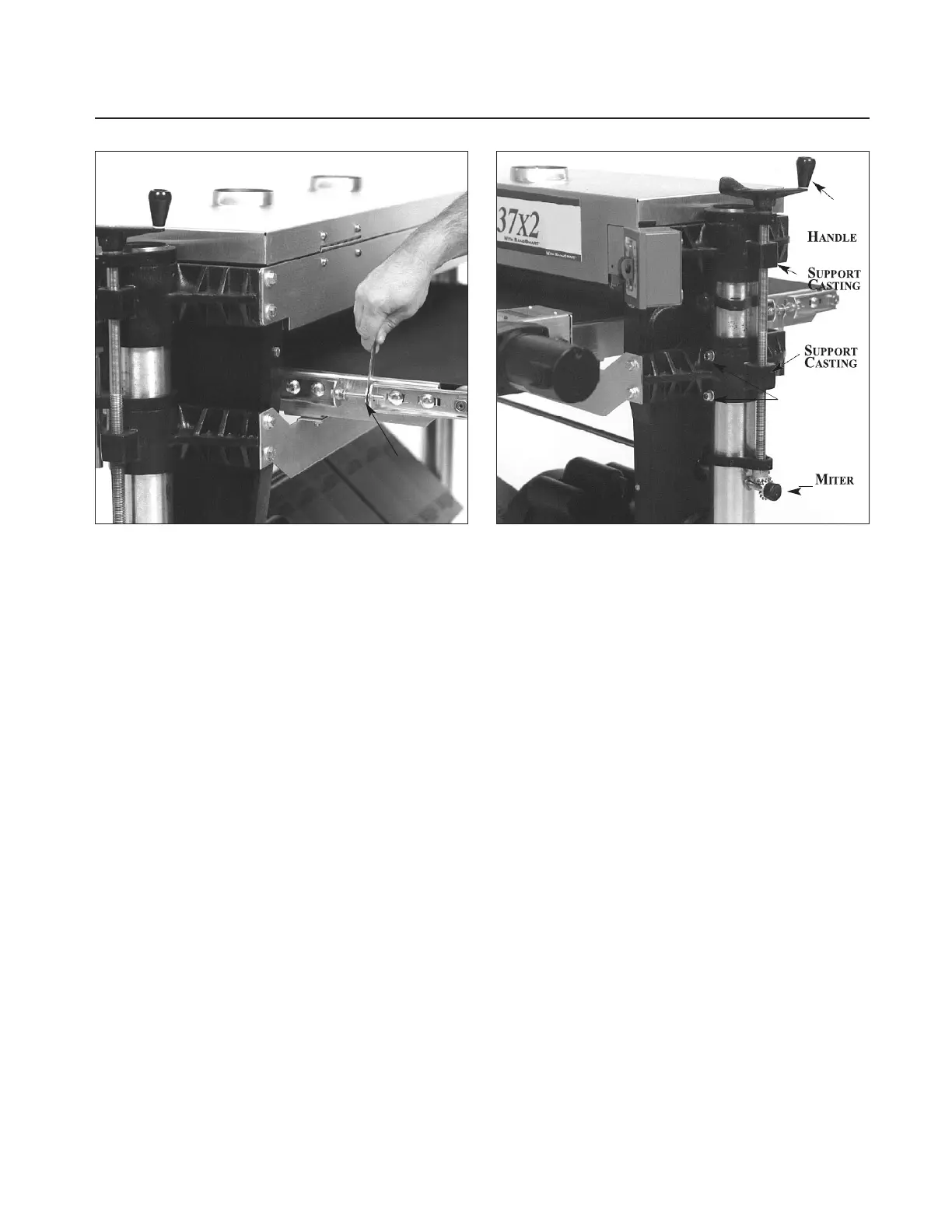

The table height and depth of cut is controlled by

the height adjustment handle (see Fig. 11). Turning

the handle raises or lowers both sides of the table

simultaneously by transferring the handle rotation

through the miter gear and cross bar assembly.

Important: Before using the height adjustment,

be sure to loosen both the set screws located on the

front of both table support castings (see Fig. 3 and

Fig. 11) to allow the table support to slide on both

column tubes. These set screws are tightened for

shipping and must be loosened and readjusted to

Fig. 11. Table height adjustment mechanism.

allow the table support castings to move freely on

the column support tubes. Readjust the set screws

just so they eliminate free-play between the table

support casting and the column tube. To properly

adjust, tighten the set screws (see Fig. 3) only finger-

tight so they lightly touch the column tubes. Then

hold each set screw in position with an Allen

wrench and tighten the hex nut.

Check the operation of the height adjustment

mechanism. If it does not operate smoothly or eas-

ily, further adjustments may be necessary. Refer to

the servicing section of this manual, which begins

on page 24, for further adjustment procedures.

MONTHLY MAINTENANCE

For best results, perform the following recommend-

ed maintenance procedures on a monthly basis:

•

Lubricate conveyor bushings and check for wear.

•

Lubricate all moving parts, such as threaded rods,

washers, and column tubes.

•

Clean sawdust from the sandpaper and the con-

veyor belt.

•

Blow dust from the inside of sanding drum(s) and

the motors.

•

Check all set screws for tightness on parts such as

table support castings, bearings, conveyor coupler,

castings, pulleys, and miter gears.

Loading...

Loading...