SectionIV:Maintenance

4.0.MAI.SL-520X

MAST LOCK INSPECTION & ADJUSTMENT INSTRUCTIONS

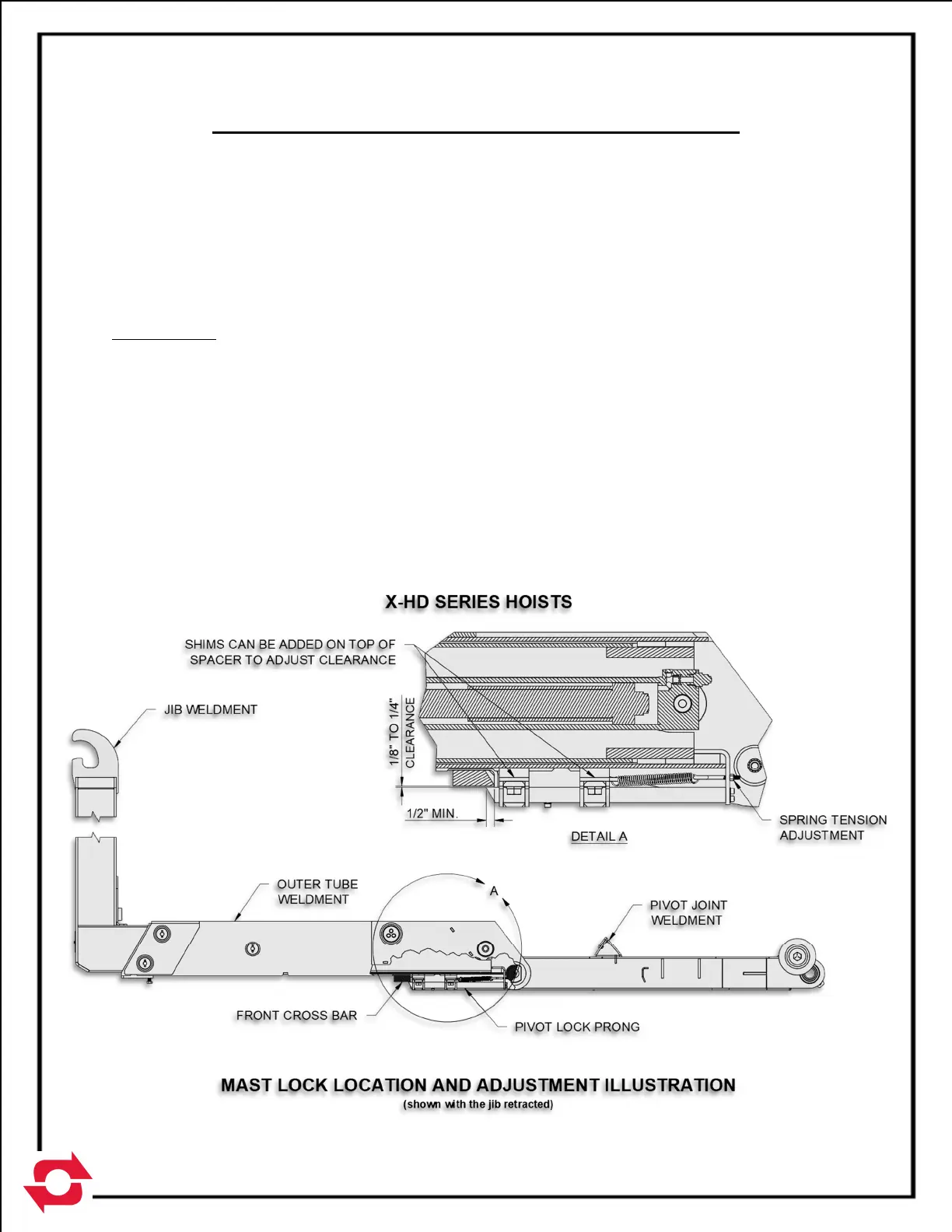

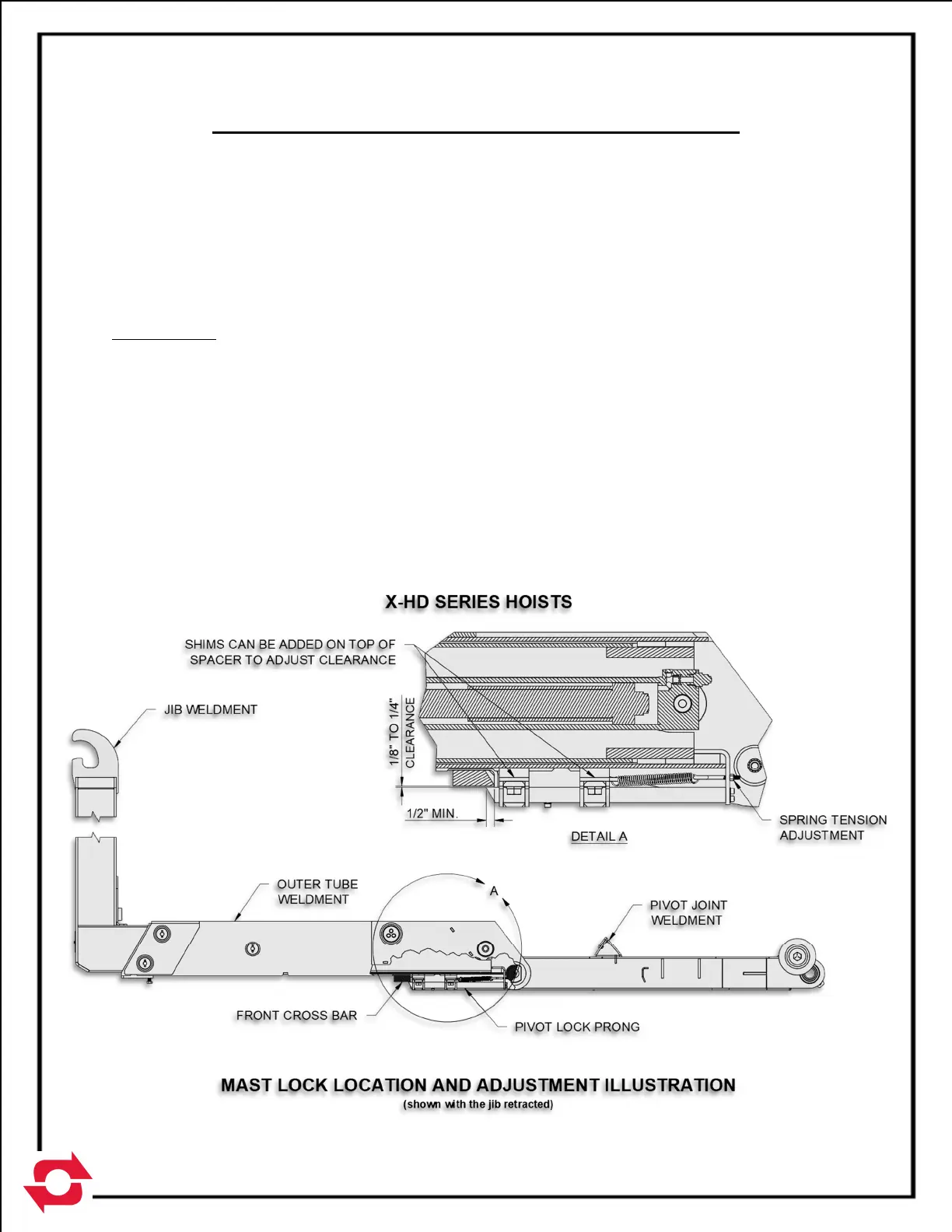

All SwapLoader hook-lift hoists come with a mast lock (safety latch) assembly that is located on

the bottom side of the outer tube. When the jib is extended the mast lock then engages the

cross bar on the pivot joint, making the jib, outer tube, and pivot joint into a continuous member

for raising the container or body into a dump mode.

With the jib fully retracted the mast lock then disengages the latch bar on the pivot joint allowing

the hook-lift to enter the mount-dismount cycle by pivoting around the front pins of the pivot

joint.

INSPECTION

The mast lock assembly comes adjusted from the factory and should provide years of trouble-

free operation, however there may come a time when parts wear or become damaged and need

replaced. SwapLoader recommends that you regularly inspect all mast lock components for

damage or wear (see illustration below).

Inspect the mast lock (see illustration below); again, make sure the pivot lock prong is not bent

and there is no missing hardware. Repair or replace any missing or bent components; refer to

the mast lock (pivot lock) assembly drawing for proper part numbers and identification of the

components (see Pg. 5-5 in the Parts Section of the manual). Proper engagement of the Pivot

Lock Prong under the Front Cross Bar is 1/2” to 3/4" when the jib is extended with 1/8” to 1/4" of

clearance.

Loading...

Loading...