SectionIV:Maintenance

4.0.MAI.SL-520X

JIB LOCKOUT VALVE INSPECTION & ADJUSTMENT INSTRUCTIONS

All SwapLoader hook-lift

hoists have a jib lockout

valve to prevent

accidental operation of the

telescopic jib, while the

hoist is up in a dump

mode. Because the jib

lockout valve can block

the flow of hydraulic oil to the jib cylinder,

should the valve come out of

adjustment the telescopic jib may

experience a reduction in

extension or retraction speed to the point of stalling out.

INSPECTION

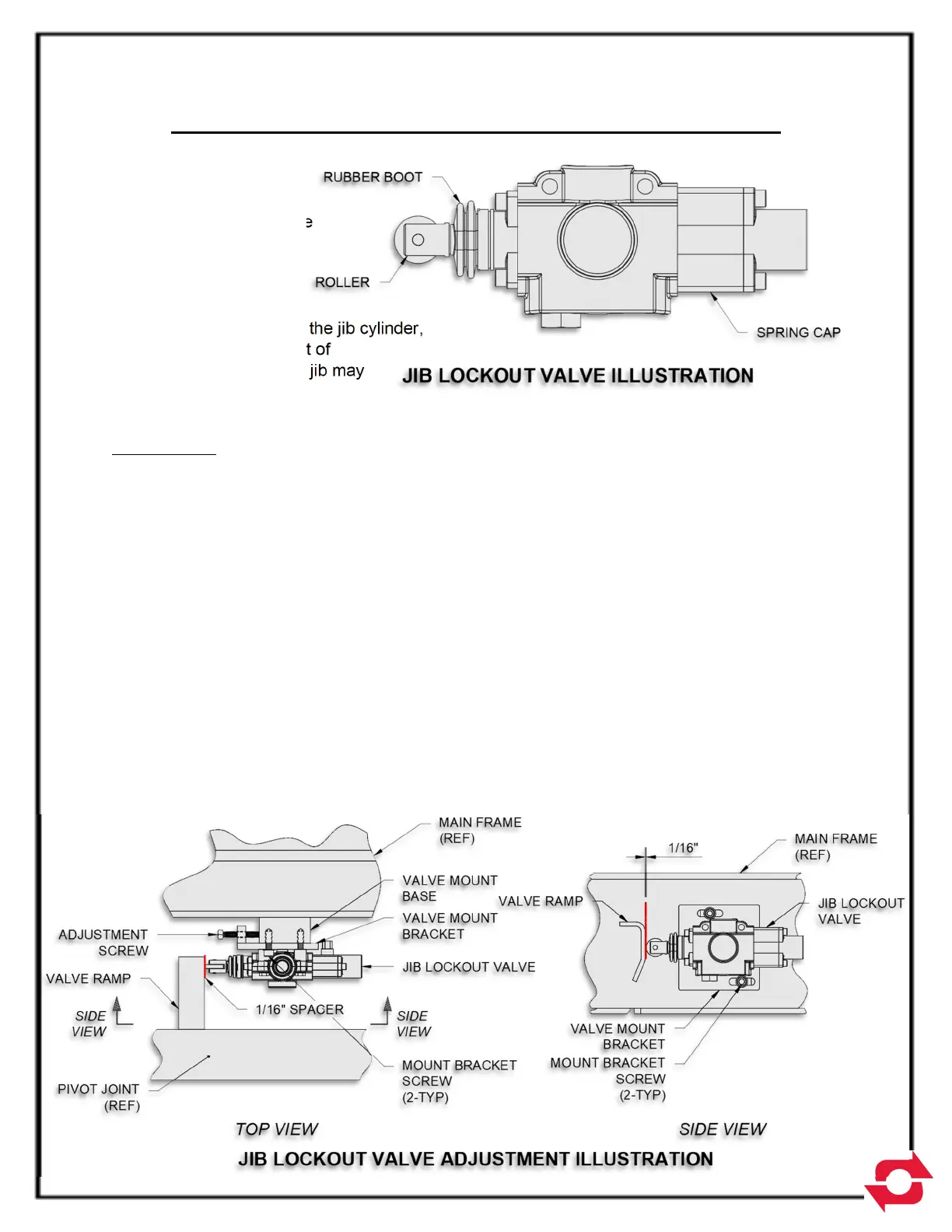

When a noticeable loss in extension or retraction speed of the telescopic jib is experienced, the

first step should be to inspect the jib lockout valve and valve mount ramp to ensure that they are

adjusted properly and in good working order. The jib lockout valve is located on the inside rail

of the hoist main frame approximately two-thirds of the way back on the driver side of the hoist

(see Jib Lockout Valve Mount Detail on Pg. 5-2 of the Parts Section of the manual). Visually

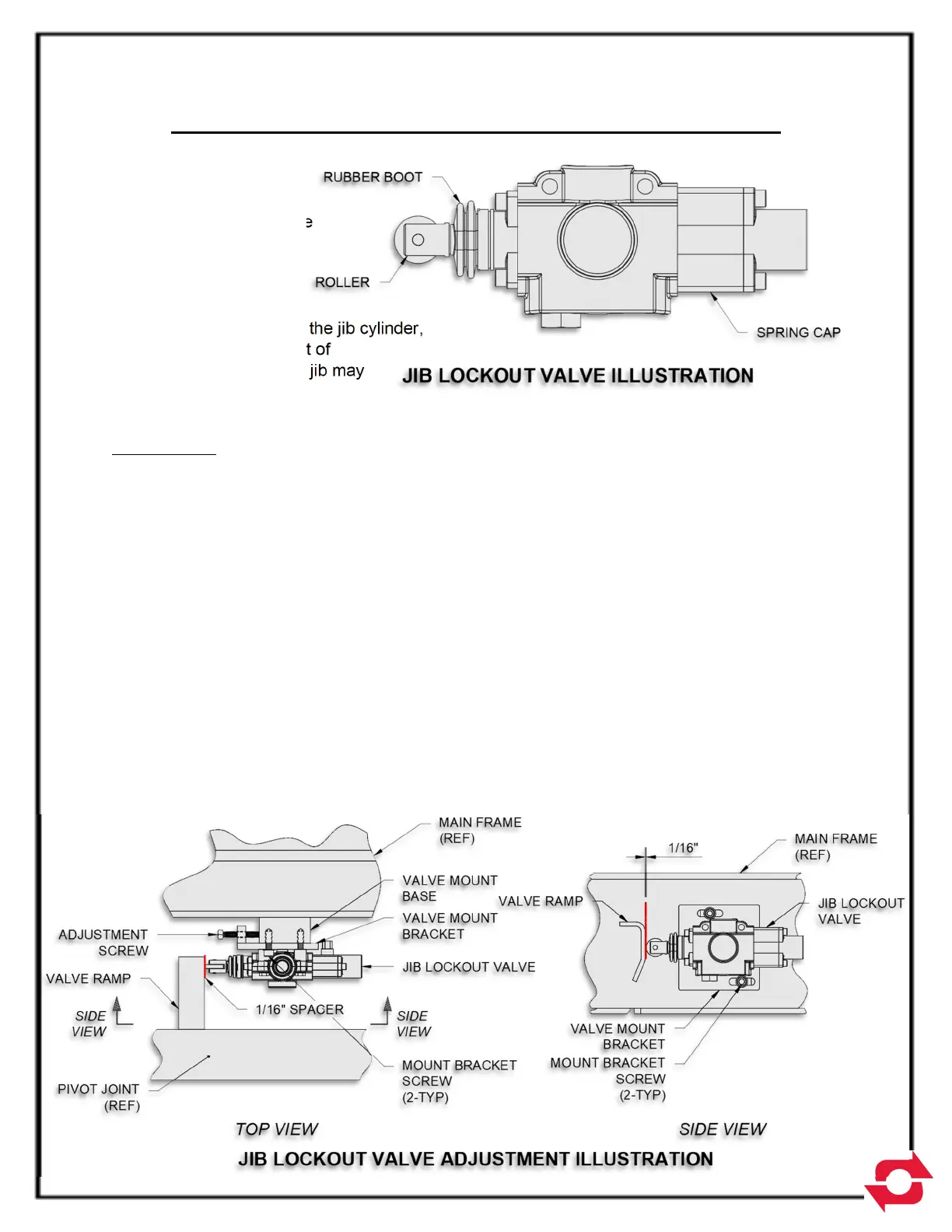

inspect the jib lockout valve roller and the condition of the valve ramp on the hoist pivot joint

without a container on the hoist (see illustration on the next page); this is most easily performed

with the hoist back in a dismount mode. If either part shows signs of wear or damage, then

replace or repair as needed.

With the jib lockout valve roller and valve ramp in good condition the next step is to check that

the valve is positioned correctly with respect to the valve ramp. While looking at the roller end

of the jib lockout valve, notice that the roller moves in and out. With the hoist pivot joint in the

down position, or horizontal to the hoist main frame, the valve ramp should be in contact with

the jib lockout valve roller. The roller should be depressed by the valve ramp by 1/4" to 5/16”.

Loading...

Loading...