SectionIV:Maintenance

4.0.MAI.SL-520X

MAINTENANCE INSTRUCTIONS

WEEKLY SERVICE

(50 OPERATIONS)

1. Lubricate with grease (refer to lubrication diagram).

Lifting hook on jib (if operating the adjustable jib be sure to

rotate and grease hook).

Jib slide - top, bottom, and side guides.

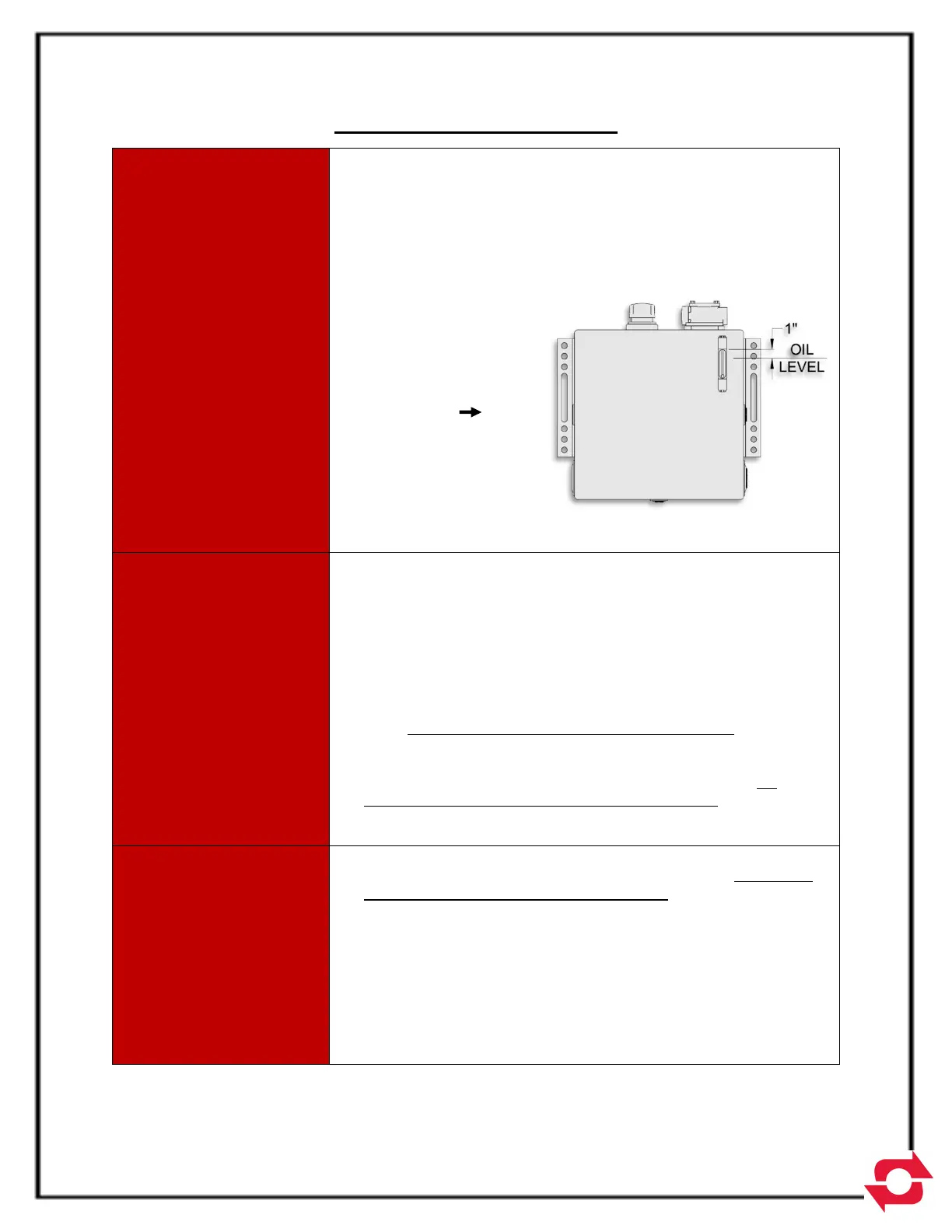

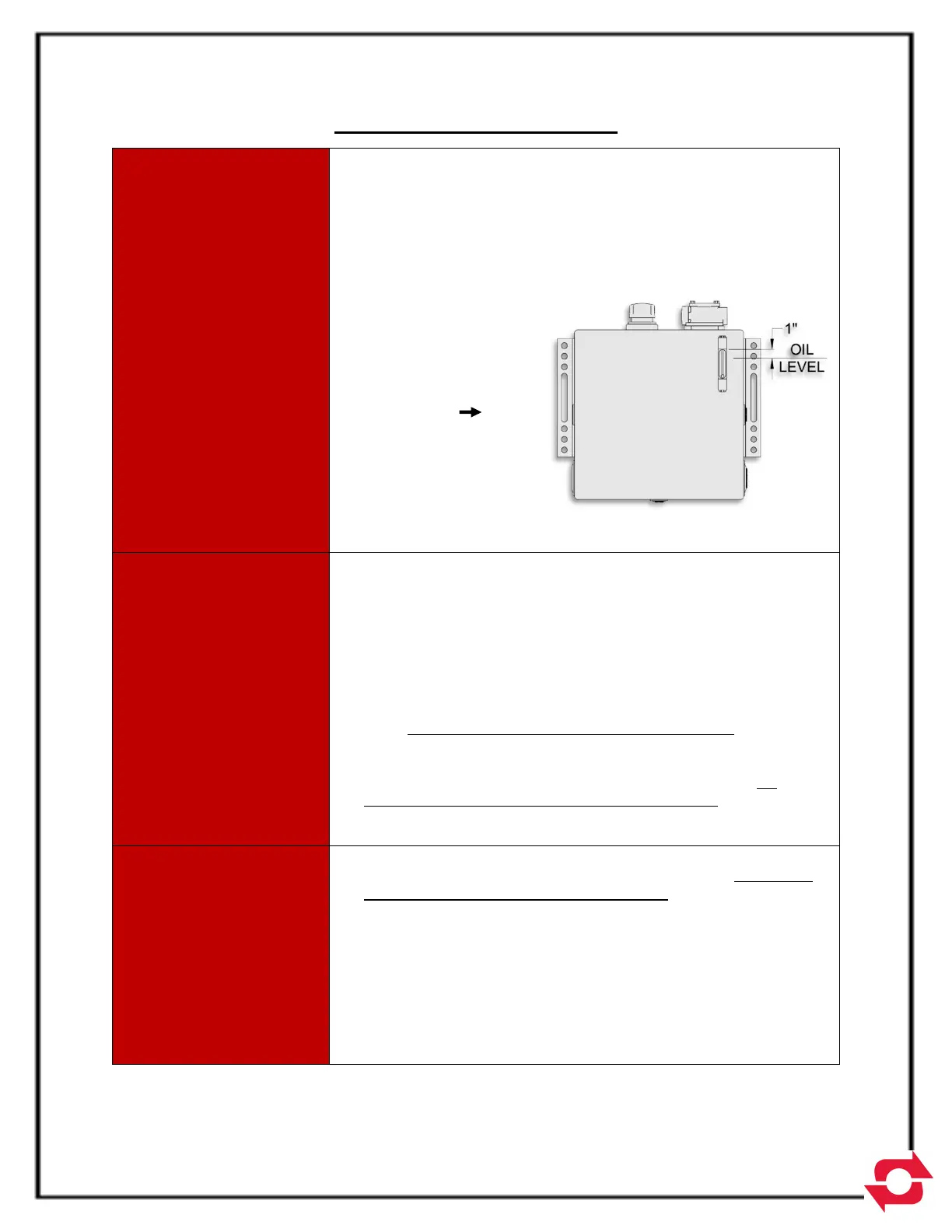

2. Check hydraulic oil level. with the hoist in the transport position (lift

cylinders retracted and jib cylinder extended – see diagram on front

cover) the oil level in the

tank should read

approximately one inch

below the top of the

glass sight on the

temperature/sight gauge

(see diagram ).

3. Check hydraulic hose

and fittings for leaks.

Also check hydraulic

hose for wear. Repair

and/or retighten as

necessary.

MONTHLY SERVICE

(200 OPERATIONS)

1. Lubricate with grease (refer to lubrication diagram)

Fittings on lift cylinders (quantity: 4).

Front pins on rear pivot joint weldment (quantity: 2).

Fittings on rear pivot pins and rollers (quantity: 4).

2. Check all bolts and retighten as required.

3. Check adjustments on mast lock (safety latch) mechanism. Refer

to the Mast Lock Inspection & Adjustment Instructions on Pg. 4-4 of

the Maintenance section.

4. Check adjustments on the jib lockout valve. Refer to the Jib

Lockout Valve Inspection & Adjustment Instructions on Pg. 4-5 &

4-6 of the Maintenance section.

YEARLY SERVICE

1. Check for proper gapping on outer tube. Refer to the Outer Tube

and Jib Wear Pad Replacement Instructions on Pg.

4-8 of the Maintenance section.

2. Change hydraulic oil, replace hydraulic filter element, and wash out

suction strainer.

3. Check main relief valve setting. Refer to the pressure check

instructions on Pg. 4-7 of the Maintenance section (pressure should

be 4,650 psi minimum).

Loading...

Loading...