D200-100-01 21 I56-3888-010

APPENDIX F

PipeIQ™ AND PIPE SYSTEM DESIGN

PipeIQ is a design application to help a user create EN54 compliant

pipe layouts. Generating a suitable working design will require

some thought and understanding of the interacting variables in an

aspirating system.

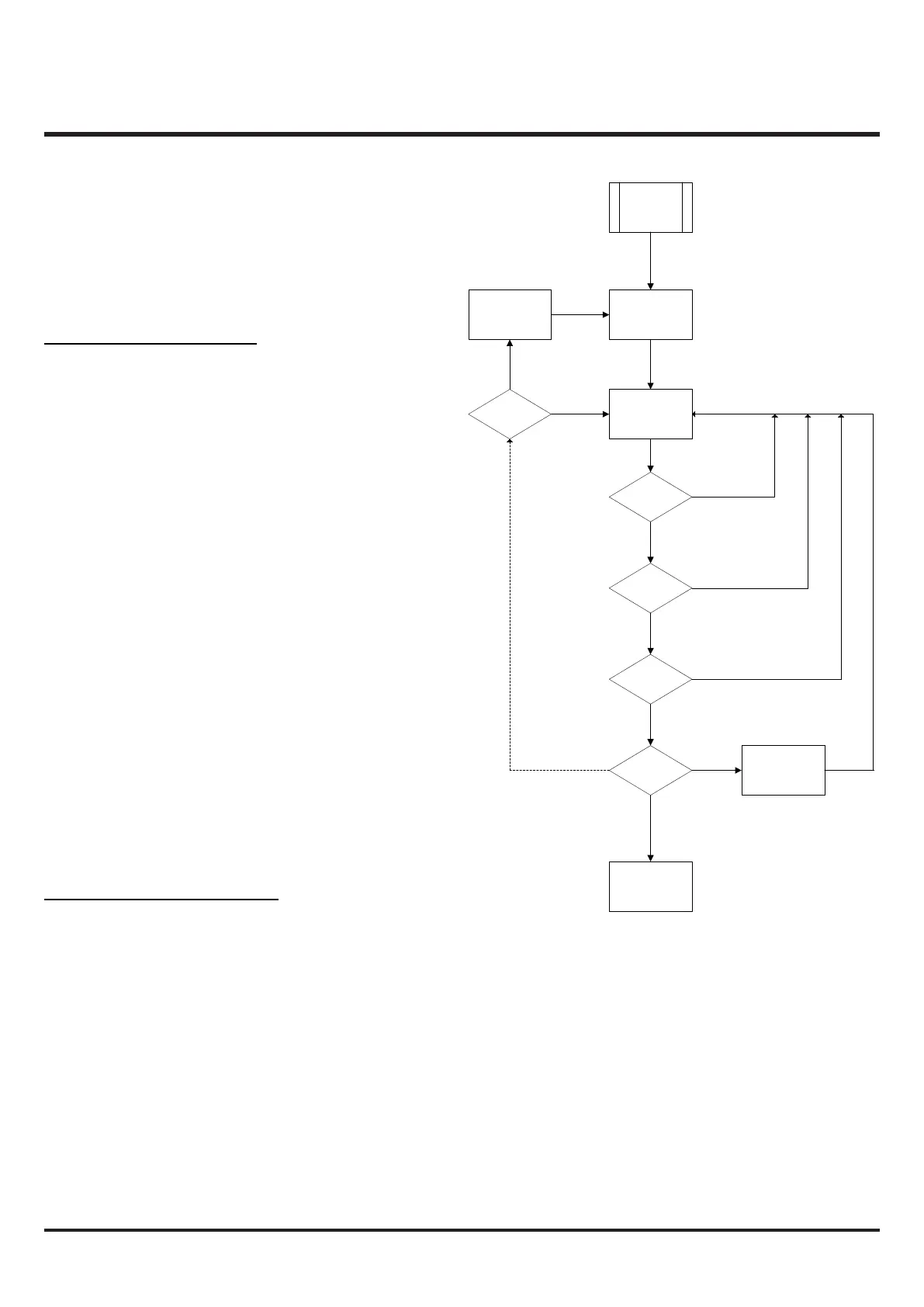

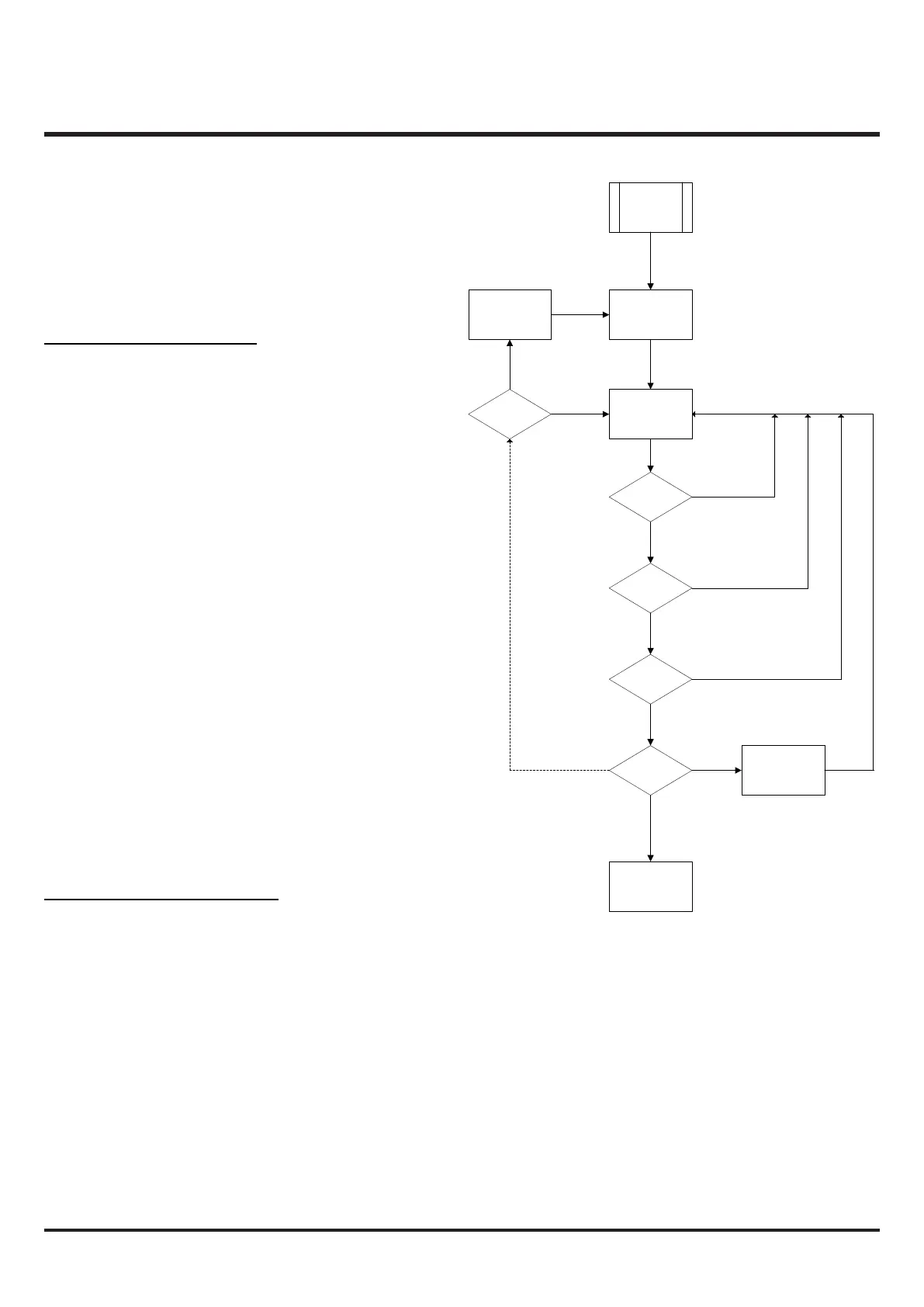

The following methodology can assist when trying to design a

pipe network using PipeIQ. By following this sequence of steps,

it should be possible to arrive at an acceptable design (assuming

one exists) that has adequate air ow and hole sensitivity to

operate within the overall limits of the aspirating device. (See Pipe

Design Methodology Flow Chart.)

Suggested Design Methodology

1. Start a project in PipeIQ, choose the detector type, select the

aspirating class and follow the instructions to add a detector

and create a representation of the physical pipe layout.

To optimise the design:

2. In the Manage Pipe – Edit Properties window, set the number

of sample holes and hole spacing in the pipe network to comply

with local re regulations and the EN54 approved gures. The

hole diameters can also be set in this window, or changed later.

To end, click Update Holes and then OK.

3. In the Design tab, click on the Calculations button; the

Calculation window will appear. Set the sample hole diameters

and fan speed to get the ow in the detector close to 45l/min.

4. Repeat step (3) above to eliminate any red boxes (out-of-range

sensitivity, transport time etc.)

5. Check the ow balance is ≥0.5. Using the auto-balance button

will probably create multiple sample hole diameters along the

pipe; avoid using this button if a single hole size is required. Be

aware that the auto-balance function may also reduce the

pipe air ow, ensure this is set back close to 45l/min.

6. Repeat from step (3), adjust hole diameters and fan speed to

achieve all the above gures.

7. Next, check that the sample hole sensitivity is practical for the

chosen class, i.e. it is not too sensitive. Ideally, to avoid false

alarms, hole sensitivity for a class C system should be 1%/m or

greater and certainly >0.5%/m.

8. If necessary, change the Alarm level to reduce the sample hole

sensitivity. The detector sensitivity is set from the Conguration

tab.

9. Repeat from step (3) to nalise the pipe design and save.

Tips to achieve an adequate design

Maintain the air ow in a FAAST LT unit at, or around, its optimum

setting of 45 l/min. Increase/decrease hole diameters and fan

speed to achieve this.

Fewer holes in a pipe will tend to increase the sample hole

sensitivity. Adding extra holes close together may mathematically

appear to reduce the hole sensitivity, but in practical terms the

system sensitivity will remain high. Change the alarm level to raise

or lower the sensitivity of the sample holes.

Changing the hole diameter will aect the hole sensitivity and the

hole balance. Smaller holes may improve the balance but will

reduce the overall ow. Ensure this remains as close to 45l/min as

possible. It is recommended that the ow balance is not less than

0.5 for an acceptable design.

Longer pipes will obviously have longer transport times; they also

tend to reduce the air ow, which further extends the transport

time. Rather than using one long single pipe, the use of a ‘T’ tap

or two pipes per channel can reduce long pipe runs and reduce

the transport time. It also helps with maintaining the air ow speed

at the optimal level, since it is equivalent to increasing the pipe

diameter to the aspirating device; but beware the ow does not

get too high. In twin pipe systems it may be necessary to reduce

hole sizes, compared with a single pipe, to achieve optimal ow.

Alternatively, the fan speed can also be reduced, but both these

actions will increase the transport time.

Use of the Auto-balance button in PipeIQ will probably give the

holes in the pipe design a variety of dierent diameters. If one

size of hole in the sample pipe is desirable (for simpler installation

and commissioning) do not use this button. Pipes with equal size

sample holes are also easier to test – the farthest end sample hole

will be the least sensitive.

Note that the fan speed setting is required to calculate the reference

air ow in PipeIQ. However, a FAAST LT device will automatically

set the correct air ow at commissioning time, when used in the

normal auto fan mode (set as default). It is not necessary to set

the fan manually.

Pipe Design Methodology Flow Chart

Set number of

holes and hole

spacing

Start Project

and create

pipe layout

Set sample hole

diameters and fan

speed

Is air flow

c.45l/min?

Are the

parameters in

range?

Is the flow

balance ≥ 0.5?

Is hole

sensitivity OK

for class?

Change alarm

level

Save design

Y

N

Y

N

Y

Y

N

N

Review pipe

layout

Is a design

possible?

N

Y

??

PIPE DESIGN METHODOLOGY FLOW CHART

Loading...

Loading...