32

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

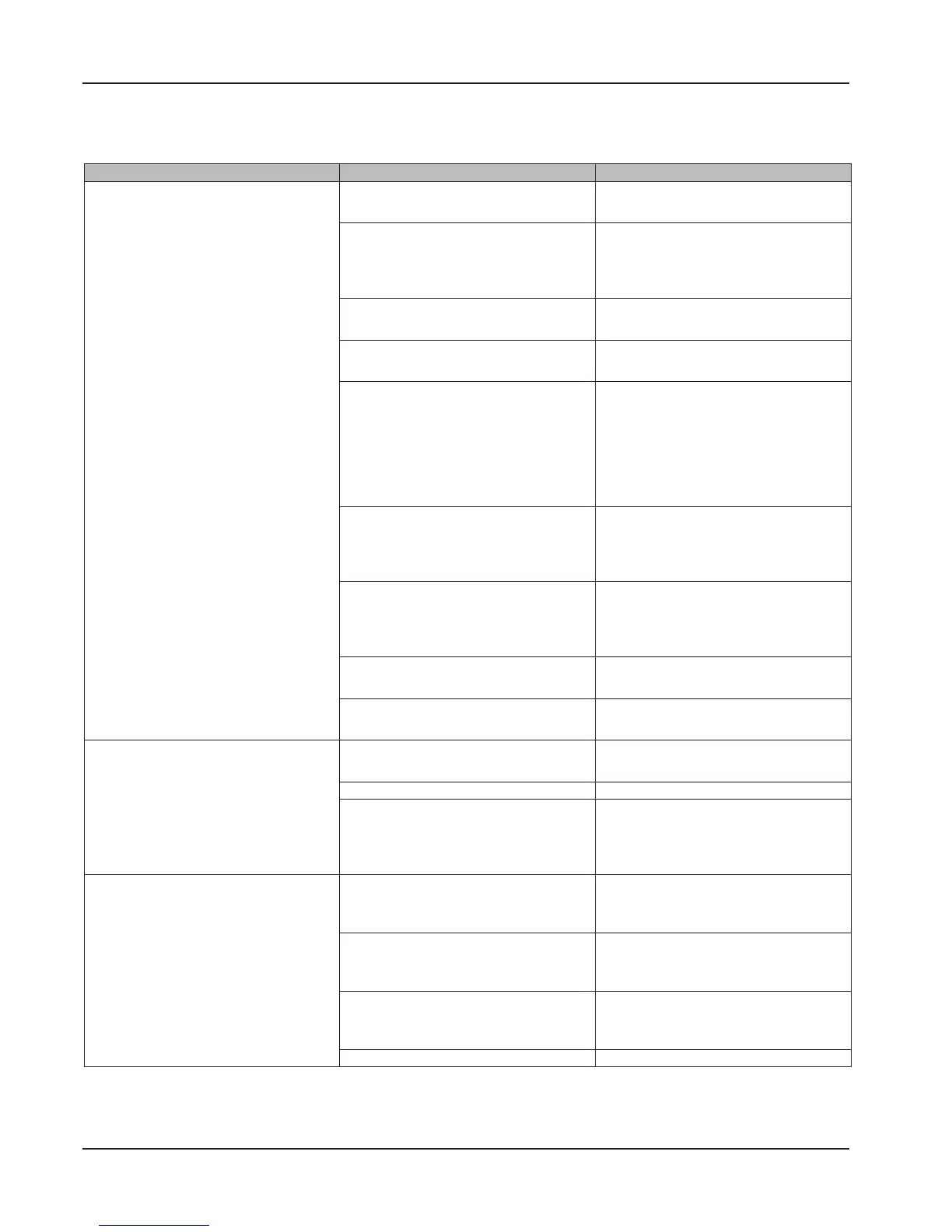

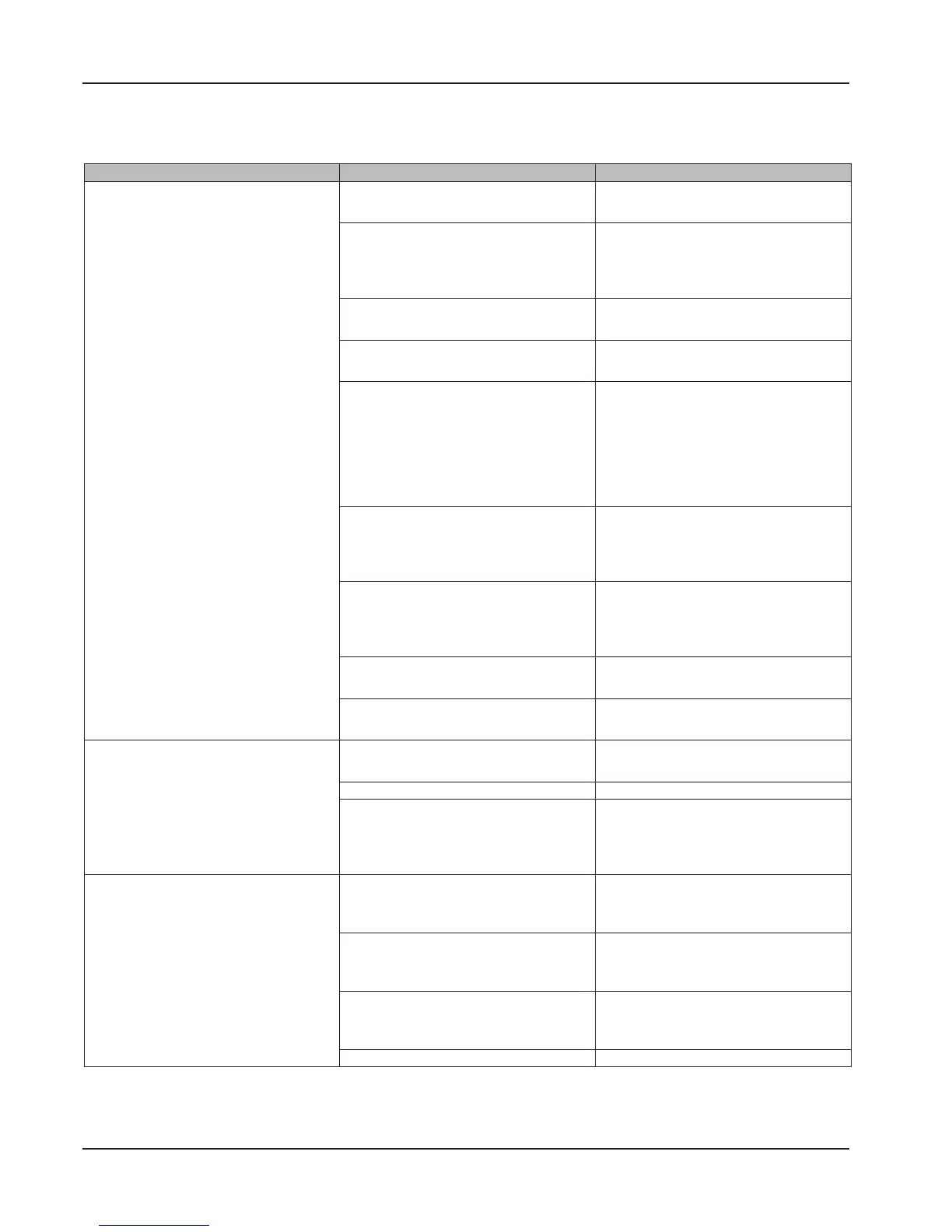

3.14 Malfunctions and solutions for electronic devices (Mod. K21E, K28E,

K40E, K55E, K28VE, K40VE, K55VE, K21FE, K28FE, K40FE, K55FE)

DEFECTS CAUSES SOLUTIONS

1. The “red” lock-out light swit-

ches on.

a) There is no gas or the pressure is

too high.

a) Check the supply pressure on the

valve (5 Draw 30a).

b) There is no electrical spark dis-

charge on the burner.

b) Check the condition of the starting

electrodes, the respective spark

detection system, and the position

of the starting electrodes.

c) The electric polarity of the neutral

phase has been inverted.

c) Invert the polarity of the neutral

phase.

d) The device has not been correctly

grounded.

d) Ground the device correctly.

e) There is a malfunction in the elec-

tronic unit (in most cases this is

due to electrical discharges produ-

ced by lightning. We recommend

disconnecting the electrical power

supply during periods when the

device will not be used.

e) Replace using original spare parts.

f) Air is present in the pipes and cau-

ses the device to lock-out after 10

seconds of discharge on the bur-

ner.

f) Switch the bipolar switch equipped

with the “orange l.e.d.” off and on

to reset.

g) The centrifugal fan positioned in

the combustion air suction circuit

is malfunctioning (no starting

occurs).

g) Replace using original spare parts.

h) failure of one or both coils of gas

solenoid valve.

h) Replace with an original spare part

i) failure of the redresser bridge of

gas solenoid valve

i) replace with an original spare part

2. The tangential fan for the supply

of surrounding air fails to start

working.

a) The fan is jammed.

a) Check and remove all foreign

objects.

b) The fan motor is malfunctioning. b) Replace the entire fan-motor unit.

c) The fan triggering thermostat is

malfunctioning (this can be chec-

ked by making an electric bridge

on the thermostat itself).

c) Replace the fan triggering thermo-

stat (38 - 40 °C) using original

spare parts.

3. Main burner with the flame

which is detaching

a) Gas pressure at the nozzle too

high

a) Regulate the pressure at the nomi-

nal value using the 4 intake (Draw

30)

b) Wrong nozzle.

b) Replace the nozzle with the one

corresponding to the gas actually

used

c) Exhaust pipe not correctly connec-

ted between the cast iron body

and the external terminal

c) Verify the seal of the connection

d) Obstructed terminal d) Clean the terminal

Loading...

Loading...