6

Rev. 12GB0712

SYSTEMA S.p.A.

AIRTIGHT GAS CONVECTORS

CONVECTOR FLUE GAS-AIR KIT

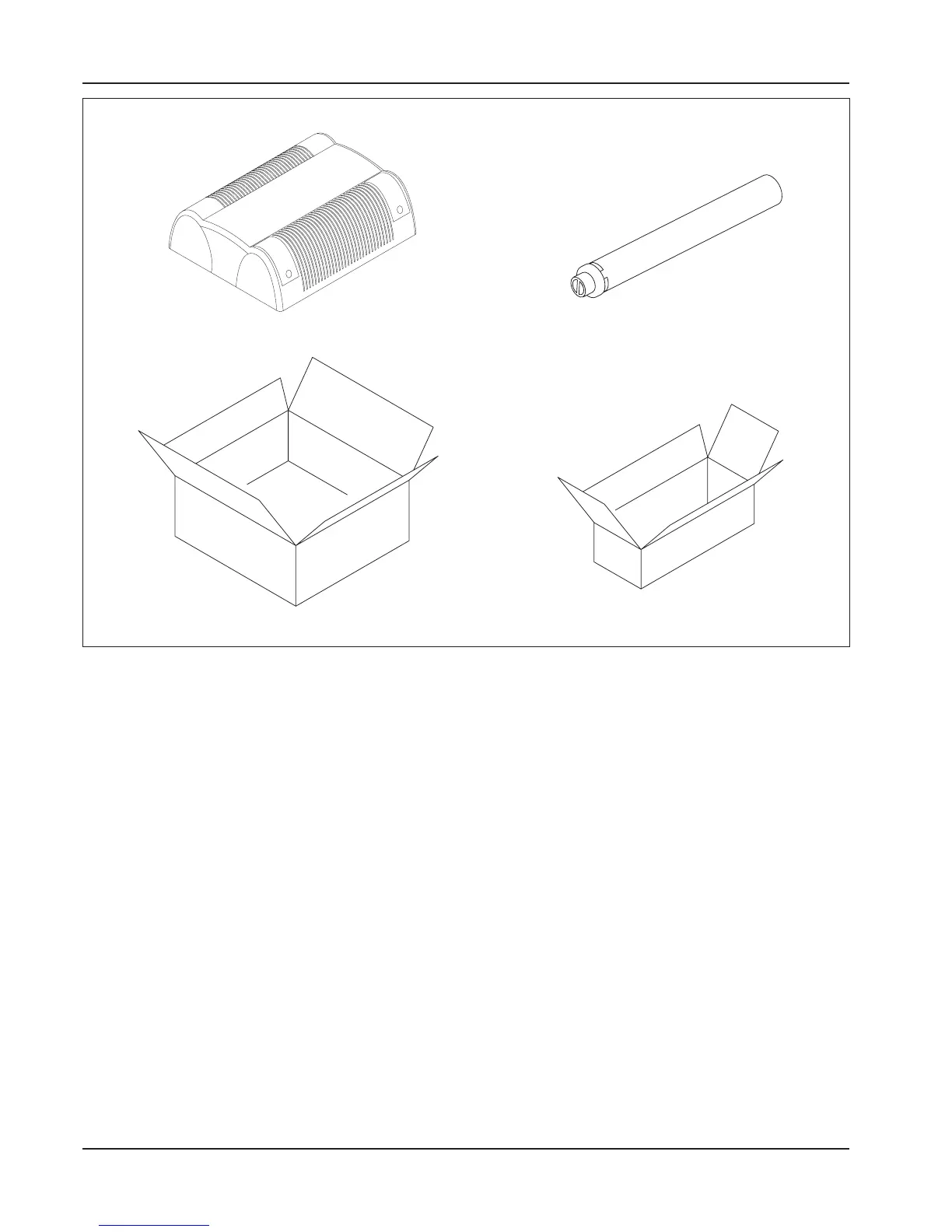

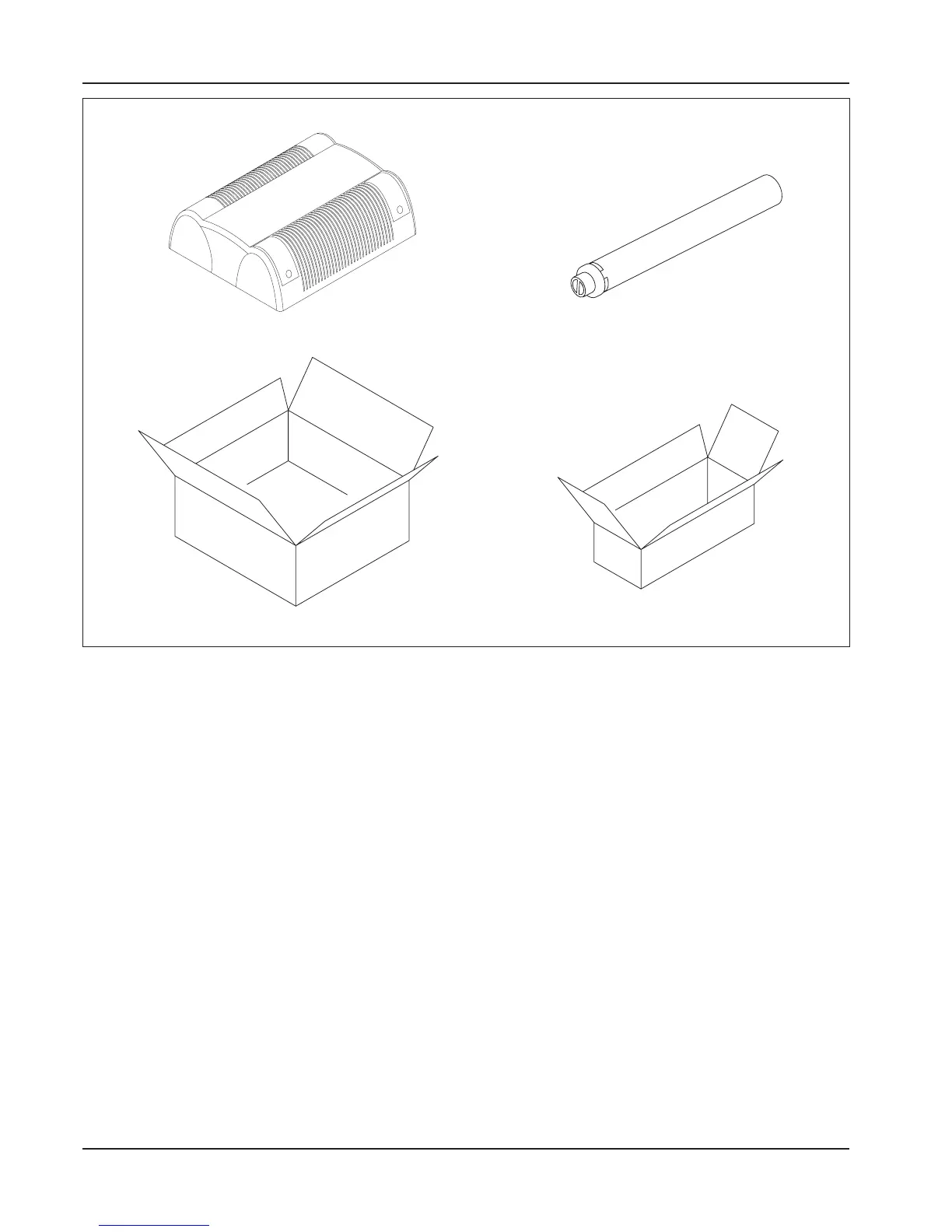

Draw 1 Package contents

2.3 Description and operational

characteristics

The airtight gas convector radiator is composed of a

combustion chamber for the combustion of a gaseous

component (methane or LPG) in airtight cast iron divi-

ded into two half-shells that can be opened for cleaning

and the inspection of the burner. The working tempera-

ture of the external surface of the combustion chamber

as fanned by the natural convection movement of the

surrounding air or the forced circulation of the fans is

usually reached in a few minutes.

The device functions automatically, and is equipped with

the appropriate systems for safety, control, mixing, com-

bustion, starting, the suction of combustion air and flue

gas expulsion.

The combustion air suction and flue gas expulsion

systems must be mandatorily connected directly to the

building’s exterior (C-type devices) and therefore there

is no contact between the combustion chamber and the

building’s interior. This guarantees the maximum safety

and permits the installation of the device indoors in com-

plete respect of the standards in force.

2.4 Principal elements of the con-

trol and safety systems

a) Electric control unit for the Electronic series

models: this can be of two types depending on the

convector model involved (forced or naturally

balanced circulation). After receiving the electric

signal from the room thermostat, the control unit

runs a normal check on the pressure-switch when

forced convectors are being controlled (if this check

is not positive, the control unit does not grant trig-

gering). The control unit then gives the signal for

the performance of the pre-starting lubrication of

the combustion chamber (>4 lubrications) and then

the signal for spark ignition and starting by opening

the gas solenoid valve. If no flame is detected (by

the ionization probe) within the established safety

time, the device goes into lock-out. In order to reset

after lock-out, switch off the bipolar switch with the

orange l.e.d. and then switch it back on again.

Loading...

Loading...