5-44

MAINTENANCE

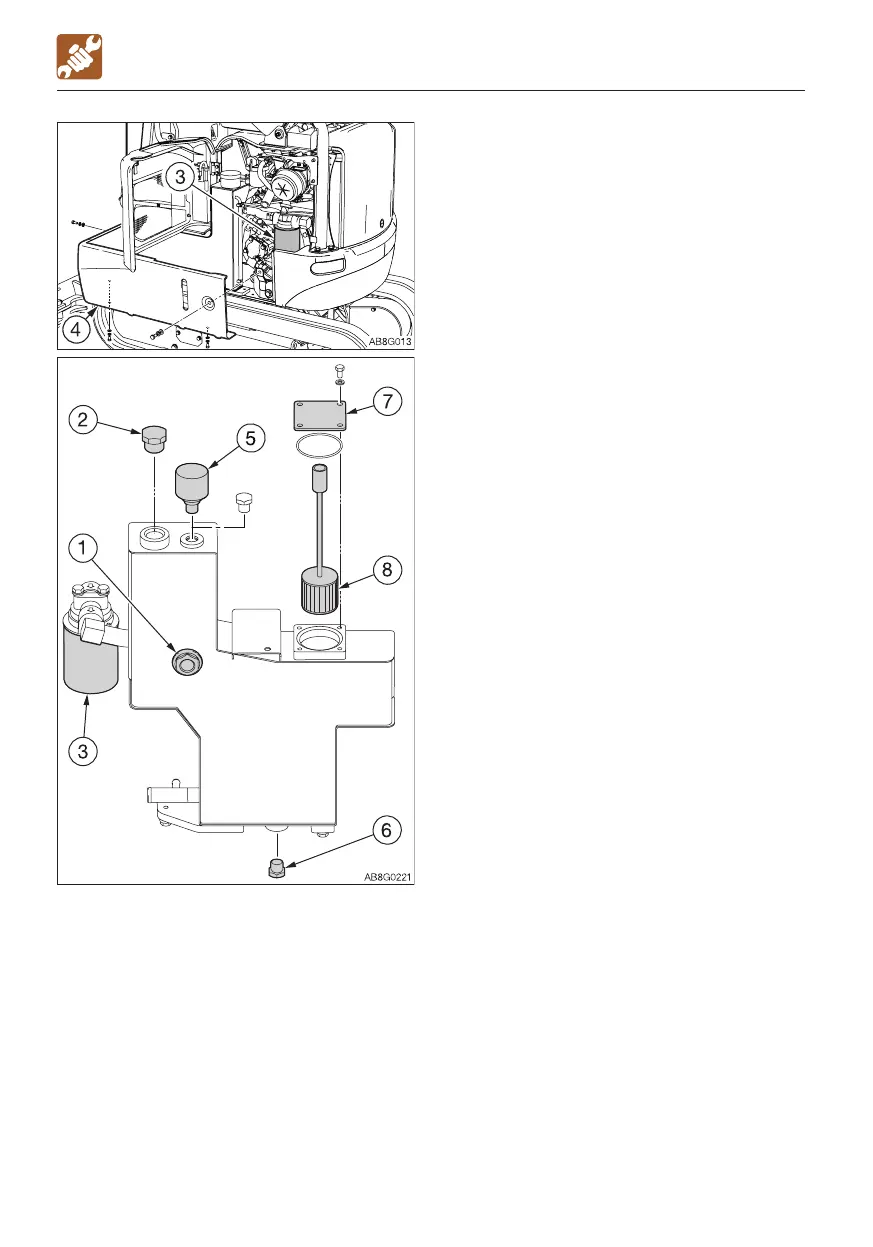

7. Place a pan for catching the waste oil

under the drain plug (6).

8. Loosen the drain plug (6) and drain the

hydraulic oil.

9. Loosen the bolts and remove the flange (7).

10. Remove the suction strainer (8) and

clean it.

11. Clean the inside of the hydraulic oil tank.

12. Replace the return filter (3).

Refer to “Replacing the hydraulic oil

return filter” on page 5-25.

13. Replace the air breather (5) (if equipped).

Refer to “Replacing the air breather (If

equipped)” on page 5-41

EVERY 2000 HOURS

14. Install the suction strainer (8).

15. Install the flange (7).

16. Tighten the drain plug (6).

17. Add hydraulic oil from the hole of plug (2)

up to the midpoint of the sight gauge (1).

18. Tighten the plug (2).

19. Bleed air from the hydraulic oil circuit

following “Bleeding air” below.

20. Set the machine to the hydraulic oil level

inspection posture and inspect the oil

level when the oil temperature drops.

Refer to “Inspecting the hydraulic oil tank

level and replenishing” on page 5-19.

21. Pressurize the hydraulic oil tank.

(If not equipped with the air breather)

Refer to “Pressurizing the hydraulic oil

tank” on page 5-20.

Note: For a machine equipped with the air

breather, no pressurization is necessary.

Bleeding air

IMPORTANT: After replacing the hydraulic

oil or hydraulic devices, or after

performing maintenance of the hydraulic

devices, bleed air from the hydraulic

circuits and hydraulic devices. Failure to

do so may damage the hydraulic devices.

• Cylinders

1. Start the engine, let it run at a low-idling

speed for 10 minutes.

2. Maintain the engine at low idle, then

extend and retract each cylinder 4 or 5

times, without let them reach the stroke

end.

3. Run the engine at high speed, then extend

and retract each cylinder 4 or 5 times,

without let them reach the stroke end.

4. Set the engine back to a low idle, then

extend and contract all the cylinders 4 or 5

times to the stroke ends.

Loading...

Loading...