90

MAINTENANCE

* : If the percentage of the traveling time within the total operating time is high, replace the

gear oil earlier than the specified time.

** : For water, use tap water (soft). Do not use well or river water.

When the ambient temperature drops below 0°C, add coolant (antifreeze). Follow the

coolant manufacturer’s instructions to determine the mixture ratio.

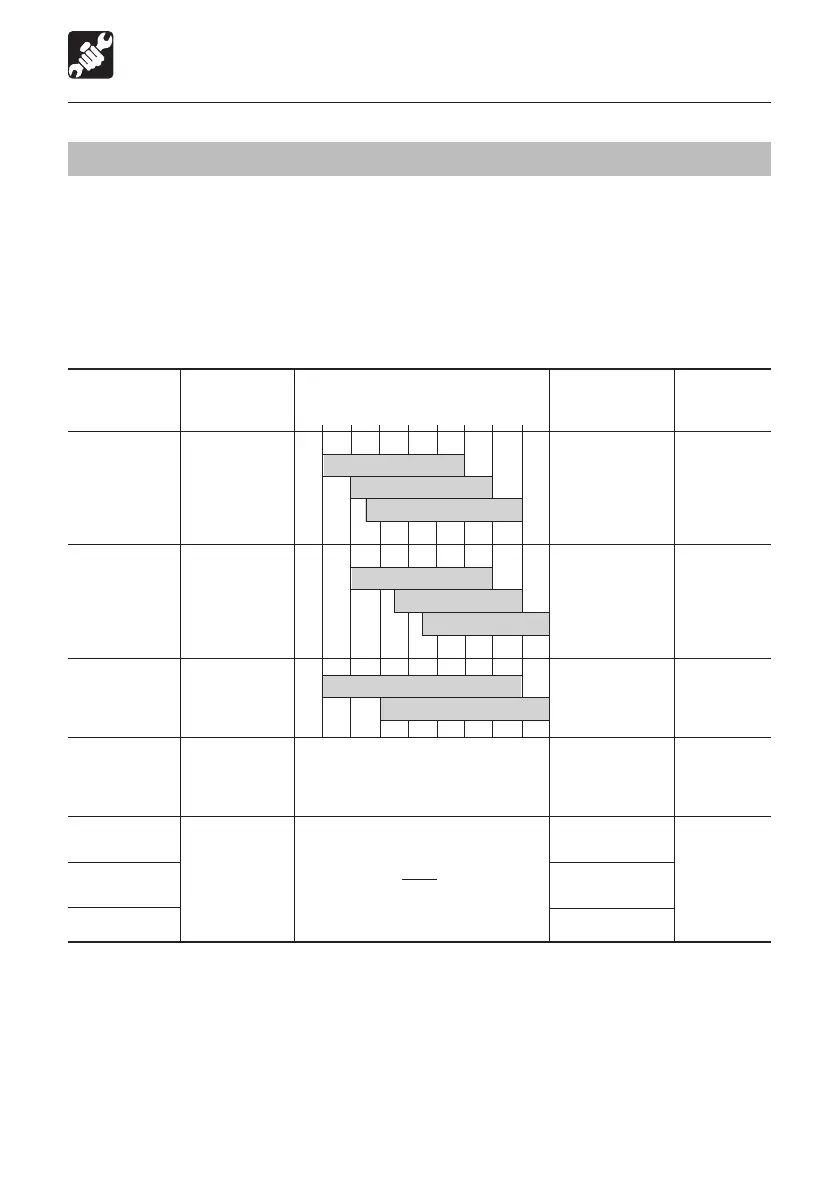

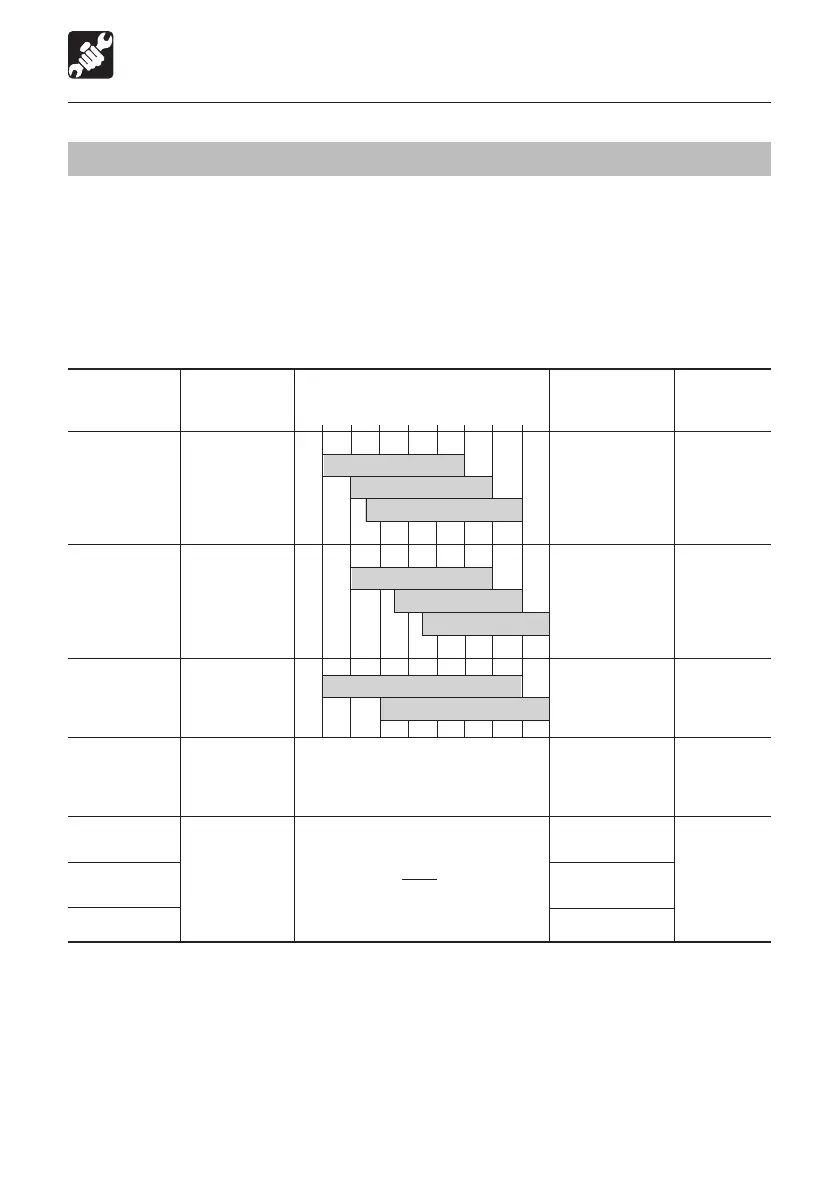

Service Data

Lubricant and Fuel Chart

Use different lubricants, greases and fuels according to the temperature, referring to the chart

below.

Change the lubricant earlier than as shown in the table if it is extremely dirty or its performance

has deteriorated severely.

Whenever possible, use the same brand of lubricant as before. If changing with a different

brand, replace the entire quantity – do not mix different brands.

Lubricants and greases

Part Type

Type by temperature

-22 -4 14 32 50 68 86

104

°F

-30 -20 -10 0 10 20 30 40

°C

Replacement

interval

Capacity

L (US. qt.)

E

ngine

oil pan

Diesel engine

oil

API-CF-4

After first 50 hrs.

Every 250 hrs.

Upper limit:

15 (15.9)

Lower limit:

9 (9.5)

System: 57

(15.1 US.gal.)

Tank: 36

(9.5 US.gal.)

Hydraulic

tank

Antiwear

hydraulic oil

(Option:

Biodegradable

oil)

Every 1000 hrs.

Engine

cooling

system

Coolant

(water +

coolant) **

Every 1000 hrs.

15 (15.9)

Travel

reduction

gear

Gear oil

API-GL-4

SAE 90

A

fter first 250

hrs.*

Every 1000 hrs.

Slew

bearing

Dump body,

Track roller

Levers

Lithium

based

grease

EP-2

NLGI No. 2

Every 50 hrs.

Daily or every

10 hrs.

When required

As required

2.6 (2.75)

SAE 5W-20

SAE 10W-30

SAE 15W-40

ISO VG32

ISO VG46

ISO VG68

50% coolant mixture

30% coolant mixture

Loading...

Loading...