HYDRAULIC PISTON FILLERS F14/25/35/50 INSTALLATION AND OPERATING MANUAL

© Talsabell s.a. All rights reserved. EN - 20 V-1.3 last revision: 07/2018

7.2 General cleaning recommendations

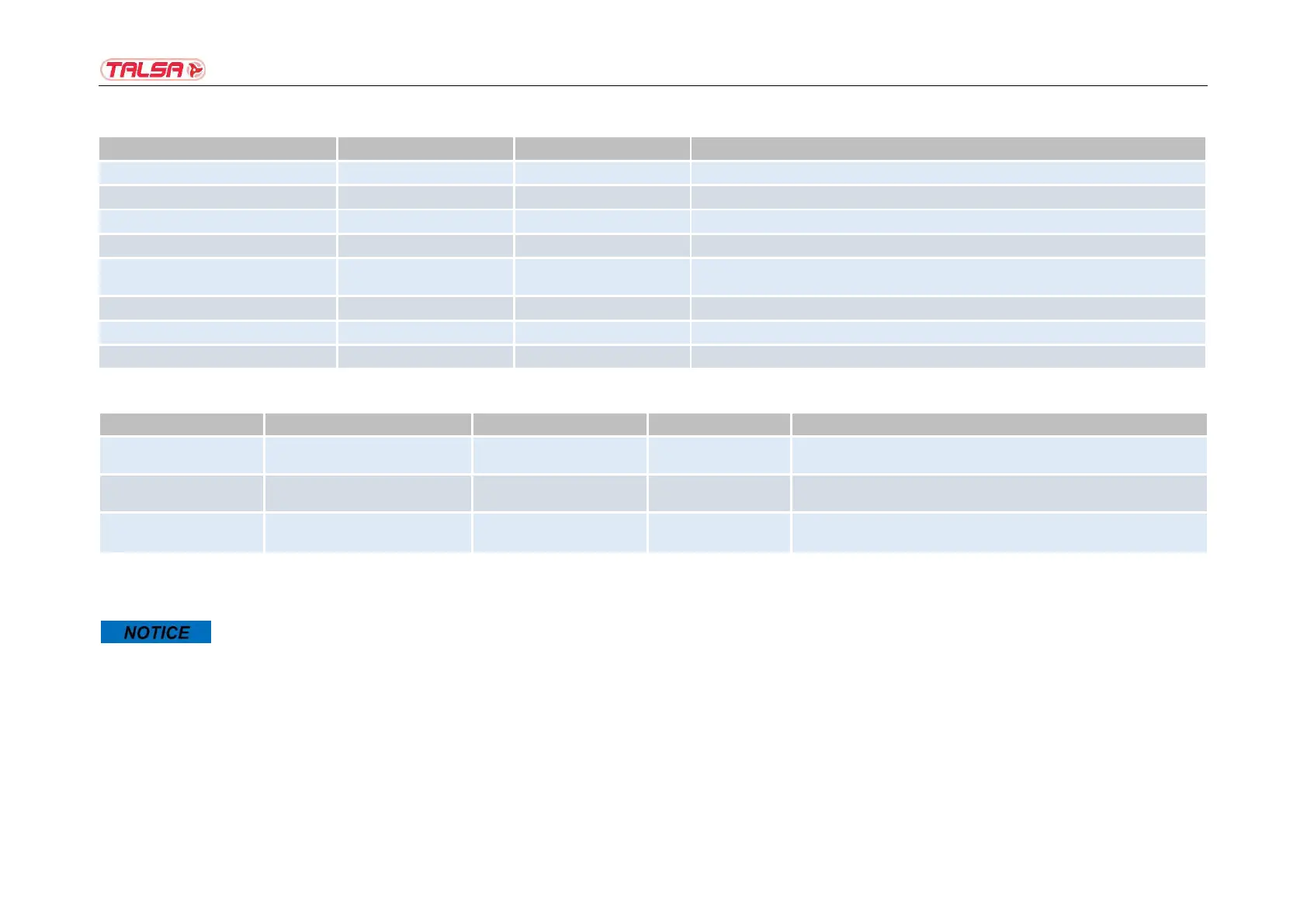

Superficial cleaning & residue removal

Allow the product to work approximately 15 minutes.

The water should be 40 to 50°C (100 to 120°F)

Visually examine all critical components, especially those subject to stress and wear.

Disinfectants; NEVER use

bleach

Disinfect after completing all other cleaning operations.

ALWAYS rinse the machine thoroughly after using detergents and disinfectants.

Be sure to completely dry all cleaned components.

Only external machine parts.

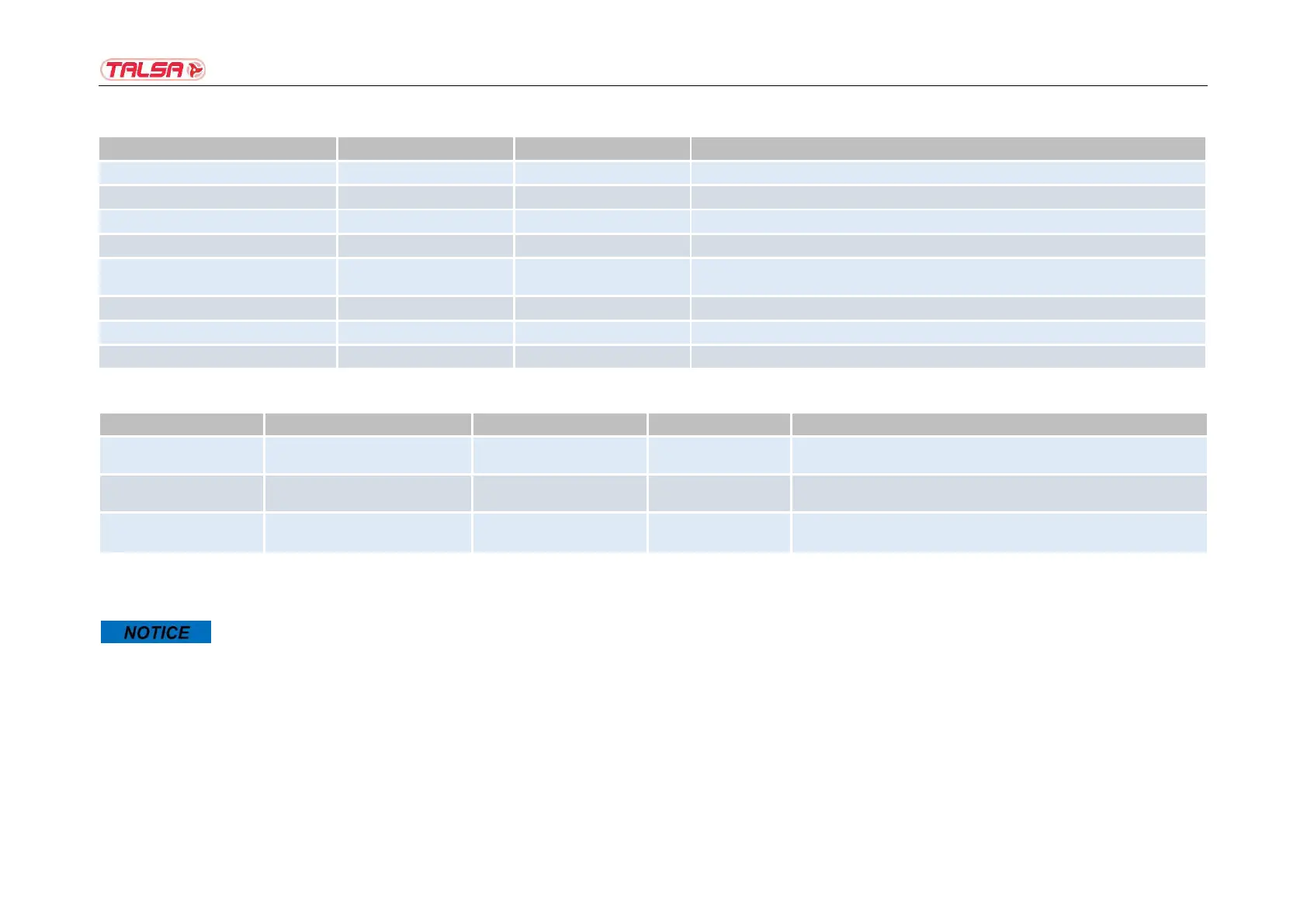

7.3 Recommended cleaning intervals

Lid, lid gasket, tank and piston

screw

Mild detergent, warm water

Remove contamination from the piston center screw using, if

necessary, a brush to prevent the accumulation of waste.

Piston, piston seals and piston

screw gasket

Mild detergent, warm water

To remove the piston follow the instructions detailed above.

Machine body, bottom of the

machine

Mild detergent, warm water

NOTE: The above cleaning intervals are suggested for companies with just one work shift. The machine should be cleaned more frequently if it is used for multiple shifts each day.

7.4 Stainless steel care

Never use aggressive cleaners with stainless steel such as bleach or similar chlorine derivatives products. If you have used it, never leave acting, rinse immediately

with plenty of water and dry thoroughly.

It is uncommon, but possible, that small traces of rust or oxidation points may be observed on the machine. This may be due to:

■ Welding impurities.

■ Food fragments adhering to the surface.

■ Pits resulting from use of aggressive cleaners such as bleach or similar chlorine derivatives products.

■ Moisture that remains after cleaning with water. ALWAYS wipe dry all components that have been cleaned.

To remove these rust spots simply use a liquid stripper with a cloth, or clean with Scotch Brite.

Loading...

Loading...