HYDRAULIC PISTON FILLERS F14/25/35/50 INSTALLATION AND OPERATING MANUAL

© Talsabell s.a. All rights reserved. EN - 23 V-1.3 last revision: 07/2018

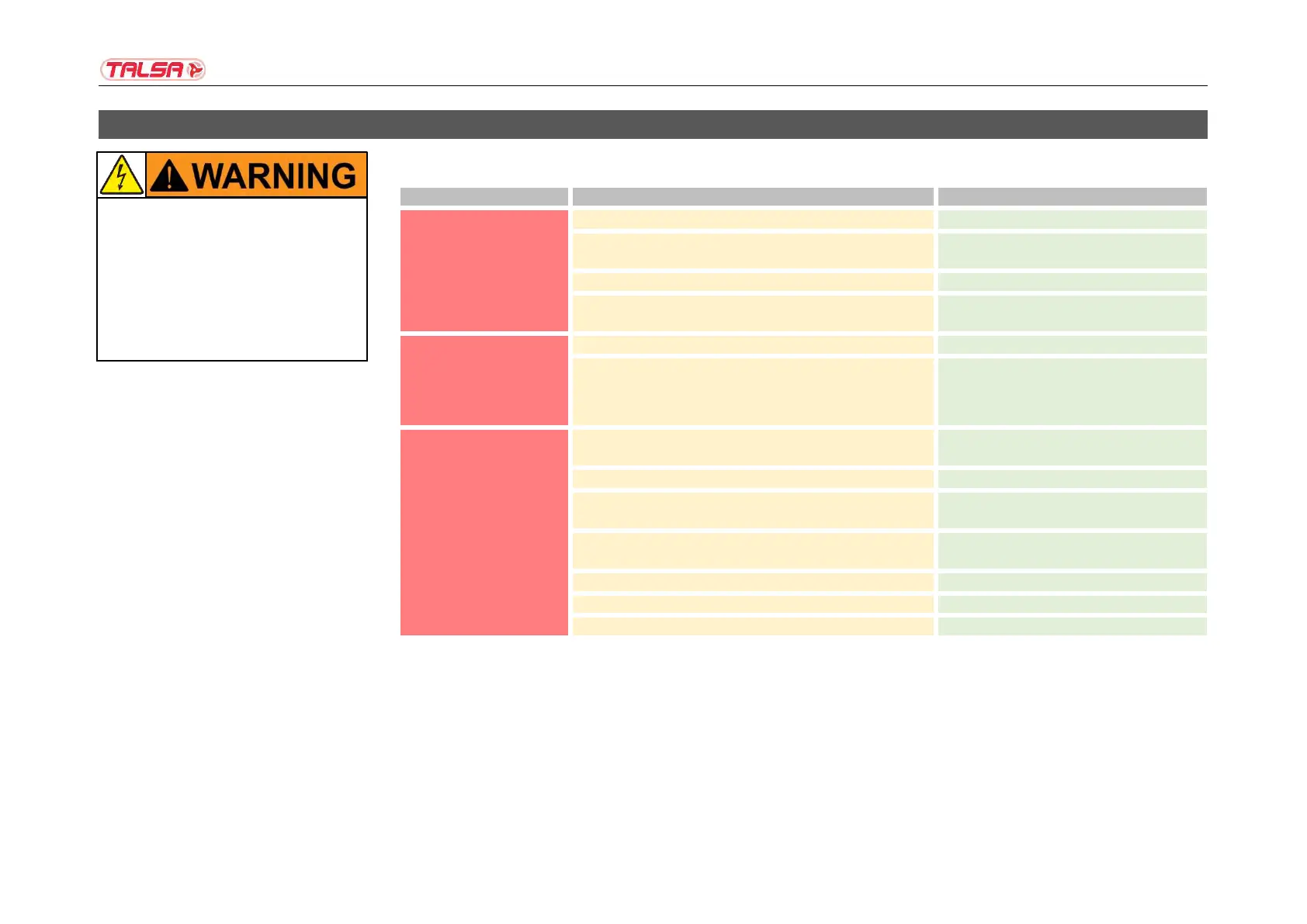

9. Trouble shooting

Talsa fillers are manufactured with the highest grade materials and components and subjected to rigorous quality controls. In the unlikely event

of some difficulty, please refer to the following table:

The machine is not working.

The machine is switched off.

The machine is connected to a lower voltage.

Change the voltage of the machine to the

right.

Without tension in one or more stages.

Check fuses, plugs and switches.

The internal micro switch on / off the knee lever is defective or

not properly adjusted.

Contact an electrician to replace or

readjusted.

The sound of the motor

rotation is heard, but the

piston does not go up or

down when pushing the

knee lever.

The pressure valve is at the minimum.

Increase pressure by turning knob clockwise.

The motor turns in the opposite direction to the correct.

Permute two of the three phases in the plug.

The piston moves up and

down but the machine

seems to lack strength.

The air passage hole located at the base of the tank is

clogged.

The piston and the piston seal are dirty.

The mains voltage is not compatible with the selected for the

engine.

Contact an electrician to change the voltage of

the machine.

The three-phase motor (if applicable) is only running two

phases.

Contact an electrician to check electric grid.

There is little hydraulic oil.

Fill the oil reservoir up to "MAX"

There is an oil leak in the fittings or pipes.

The chambers of the hydraulic cylinder are communicated.

ALWAYS power off and unplug the

machine

from the electrical outlet before

proceeding with cleaning, maintenance, or

repairs.

If you are unable to resolve the difficulty,

DO

NOT CONTINUE TO USE THE MACHINE

and contact your authorized Talsa dealer for

service.

Loading...

Loading...