- 8 -

2. Operational Principles

The MPC Series employs Tanaka Scientific's unique air pressure system (certified as U.S. standard

ASTM D 6749) to detect pour points (solidification points). Air pressure is applied to the surface of a

specimen, with subsequent motion of the sample surface measured to detect sample flow.

[System Outline]

The specimen chamber and specimen surface are divided into inner and outer regions by the pressure

conducting tube. Air pressure is applied to the specimen by a pressurizing syringe connected to the

outer region, creating a pressure differential between the inner and outer surfaces of the sample. Two

outcomes are then possible.

1. Specimen flow

The pressure differential causes the specimen to flow,

with the surface level inside the pressure conducting

tube rising (principle of the U-tube), causing a change in

pressure that is detected by the pressure sensor inside.

Upon a pre-determined pressure change, the pressure

switch is activated, indicating to the instrument that the

specimen is still flowing.

<Flow detected ⇒ Test continues>

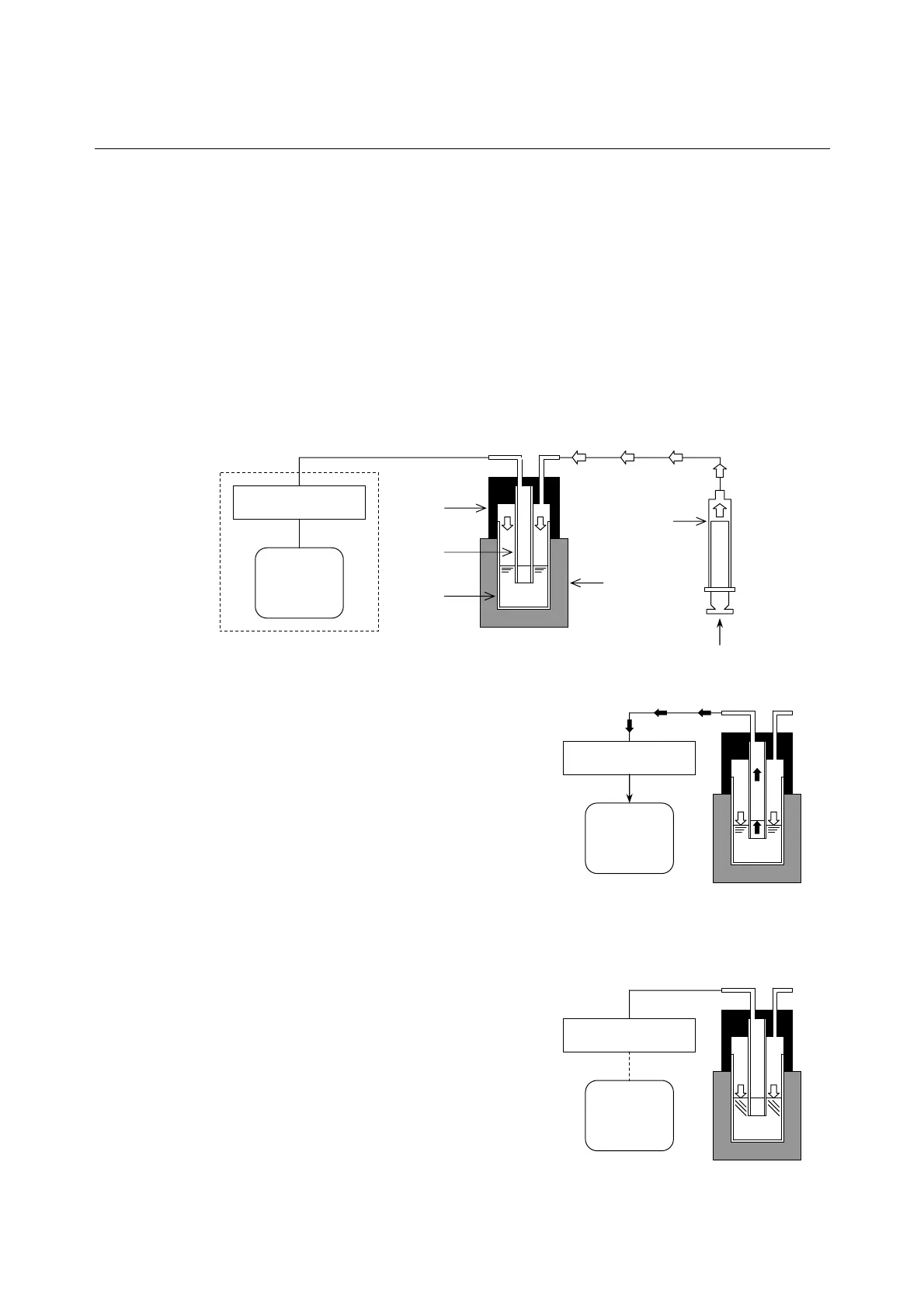

2. No specimen flow

When the specimen is not flowing, the specimen surface

levels do not change despite the pressure differential.

Thus, the pressure inside the pressure conducting tube

remains unchanged and the pressure switch is not

activated. Specimen flow is assumed to have stopped if

the pressure switch is not activated within five seconds.

<<Non-Flow (solid) detected ⇒ Test completes>

ON

Pressure rise detected

Pressure

conducting

tube

Specimen

Cup

Pressurizing

Syringe

Detector

Head

Bath

Specimen

Pressure

Switch

Pressure sensor

OFF

No pressure rise

Loading...

Loading...