USER INTERFACE

5-3

Models 750, 751, 754, 774, 791, and 794

User Interface

5

AUTO Button

When the AUTO button is pressed, the light comes on.

This indicates that the main refrigeration system has

been activated. In the Auto mode, the Wash or Standby

functions are automatically canceled. The Mix

refrigeration function is automatically locked in to

maintain the mix in the mix hopper.

Note: An indicating light and an audible tone will sound

whenever a mode of operation has been pressed. To

cancel any function, press the button again. The light and

mode of operation will shut off.

RESET Button

On counter models, the RESET button is located on the

side of the machine. On console models, the RESET

button is located in the service panel. The reset protects

the beater motor from an overload condition. If an

overload occurs, the reset mechanism will trip. To

properly reset the freezer, press the AUTO button to

cancel the cycle. Turn the power switch to the OFF

position. Press the RESET button firmly.

DANGER! DO NOT use metal objects to press

the RESET button. Failure to comply may result in severe

personal injury or death.

Turn the power switch to the ON position. Press the

WASH button and observe the freezer's performance.

Open the side access panel. Make sure the beater motor

is turning the driveshaft in a clockwise direction (from the

operator end) without binding.

If the beater motor is turning properly, press the WASH

button to cancel the cycle. Press the AUTO button to

resume normal operation. If the freezer shuts down

again, contact a service technician. (For Models 754,

774, 791, and 794, press the AUTO button on both sides

of the machine to resume normal operation.)

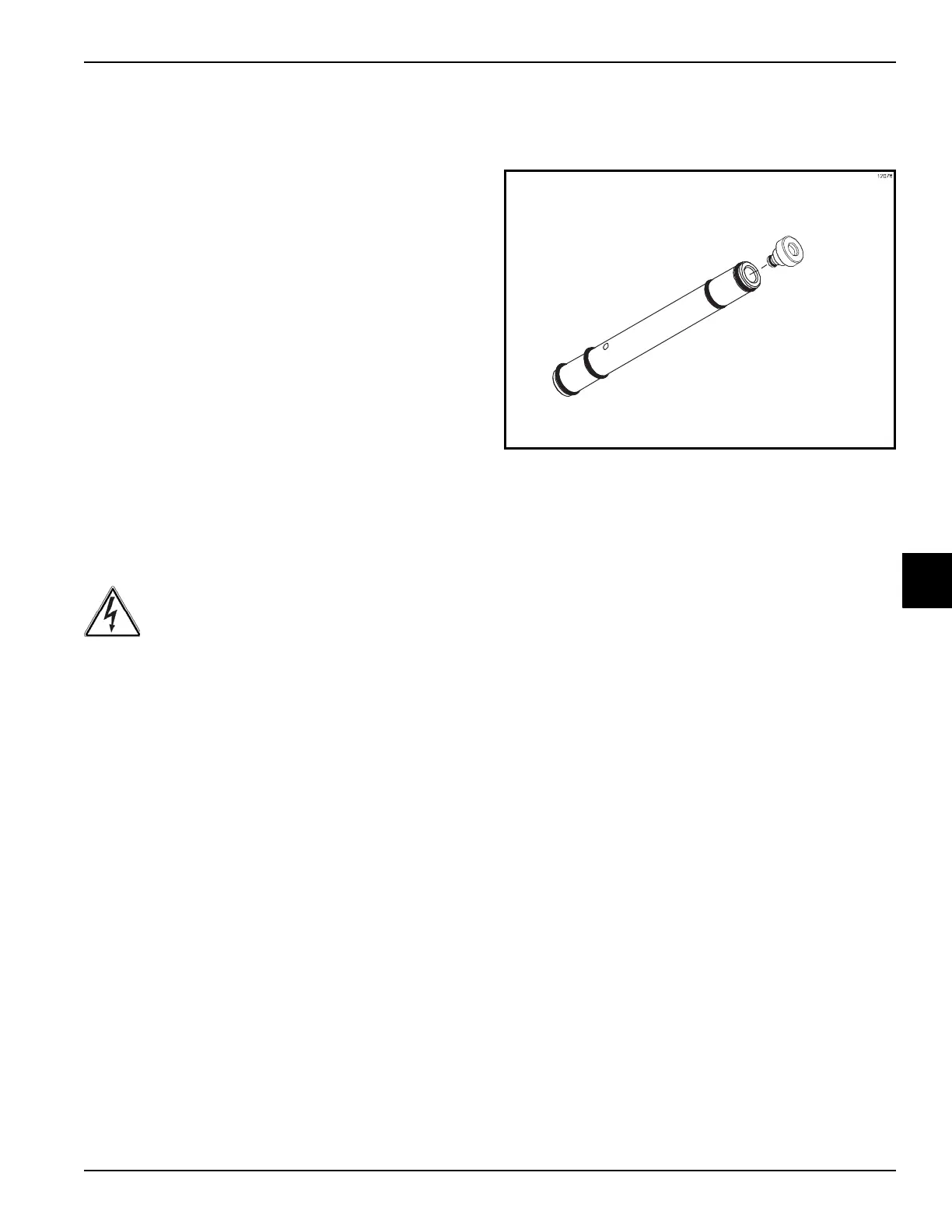

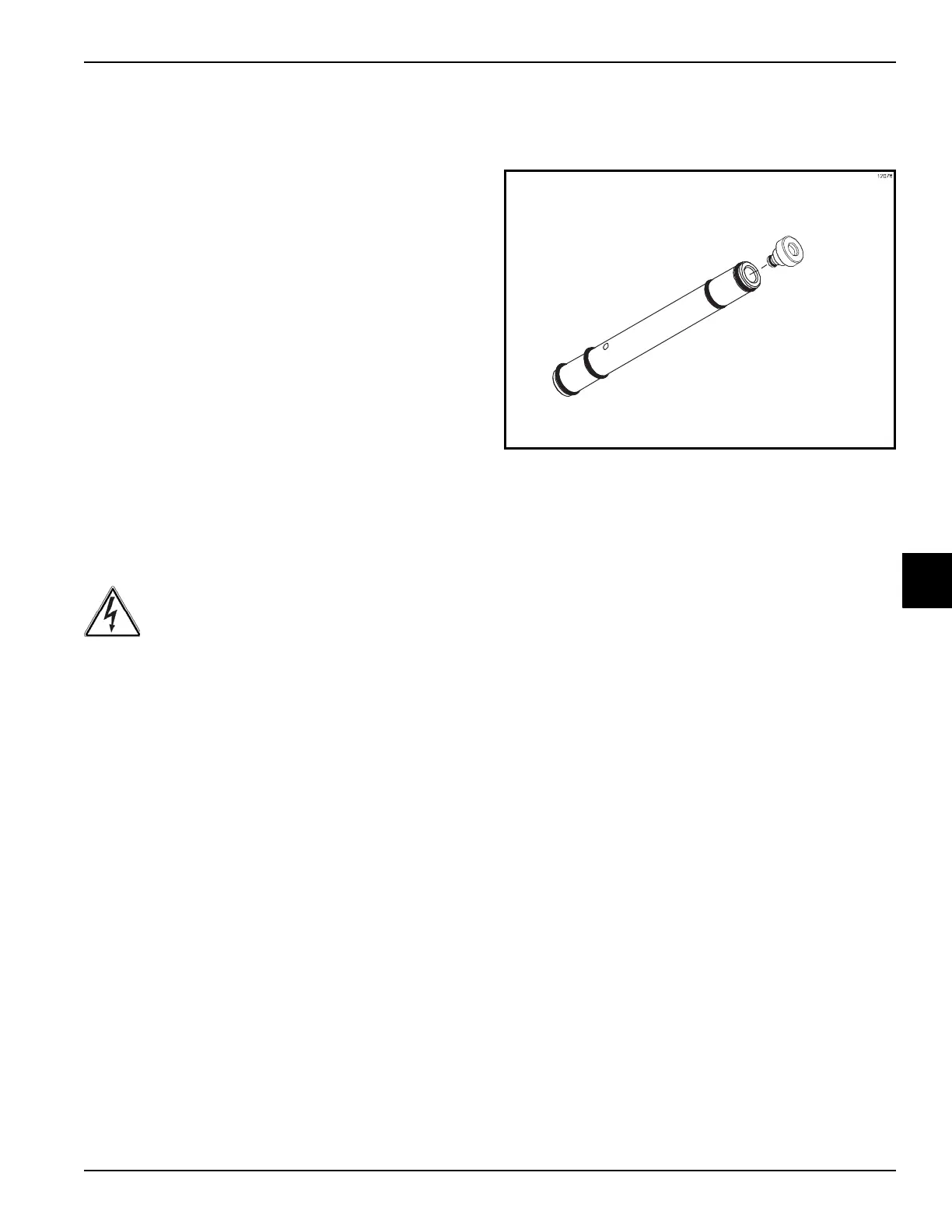

Air Tube

The air tube serves two purposes. One end of the tube

has a hole, and the other end does not.

Figure 5-3

1. After priming the machine, lubricate the O-rings on

the air tube (the end with the hole) and place it into

the mix inlet hole. Every time the draw handle is

raised, new mix and air from the hopper will flow

down into the freezing cylinder. This will keep the

freezing cylinder properly loaded and will maintain

overrun.

2. During long no sale periods, remove the air orifice.

Lubricate the O-rings on the air tube (the end

without the hole), and place it into the mix inlet hole.

This will prevent any mix from entering the freezing

cylinder.

Important! Make sure the level of mix in the hopper

is below the mix delivery hole in the feed tube.

Failure to follow this instruction may result in lower

product quality when normal operation is resumed.

The air orifice is used to meter a certain amount of air

into the freezing cylinder. The air orifice maintains

overrun and allows enough mix to enter the freezing

cylinder after a draw.

Loading...

Loading...