8-2

TROUBLESHOOTING GUIDE

085592-M

Troubleshooting Guide

8

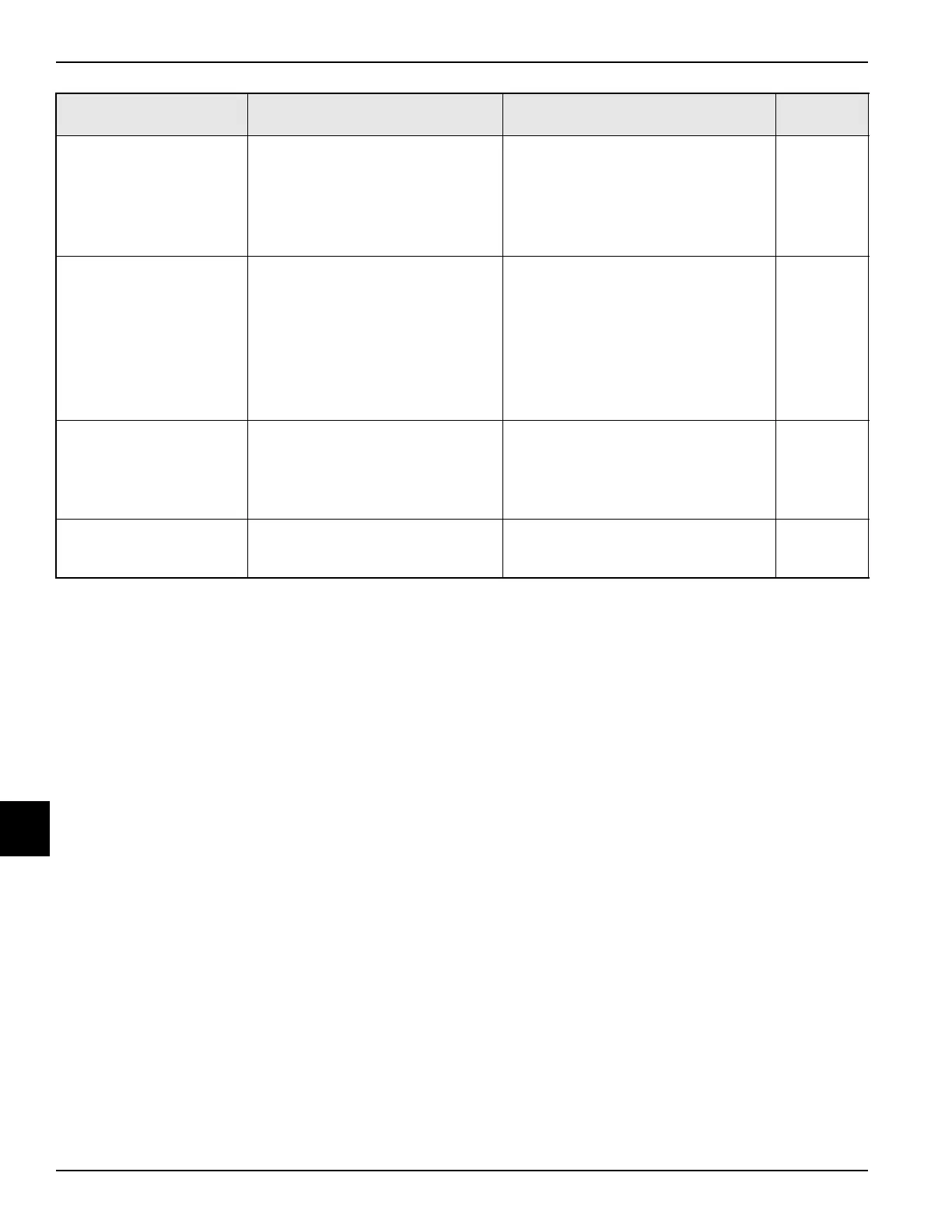

7. The draw valve is

leaking.

a. Incorrect lubricant was used. a. Use food grade lubricant (example:

Taylor Lube).

6-1

b. Worn or defective O-rings are on

the draw valve.

b. Replace O-rings every 3 months.

9-1

c. Inadequate lubrication of draw

valve.

c. Lubricate the draw valve properly.

6-1

8. Product is not feeding

into the freezing

cylinder.

a. The mix level is inadequate in the

mix hopper.

a. Fill the mix hopper with mix.

5-3

b. The air orifice is not installed. b. Install the air orifice in the air tube.

6-6

c. The air tube is installed incorrectly. c. Install the air tube in the mix inlet

hole, using the end with the small

hole in the side.

6-6

d. The mix inlet hole is frozen. d. Contact service technician.

---

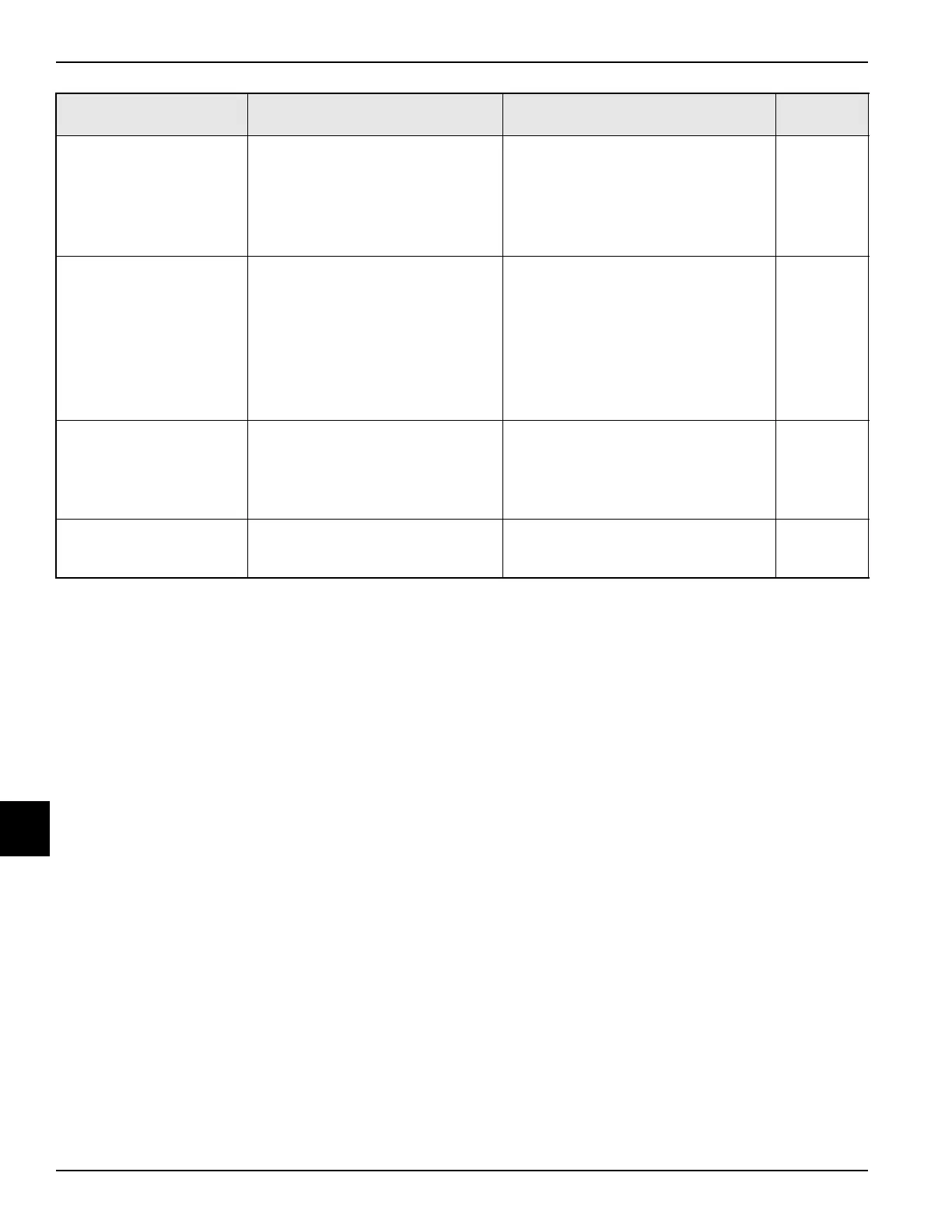

9. The unit goes out on

overload excessively.

a. There are too many appliances

plugged into the circuit.

a. A separate 20 A circuit is needed for

the freezer to operate properly.

---

b. An extension cord has been placed

between the power cord and the

wall receptacle.

b. If the extension cord is used, it must

match the power cord in size of circuit

ampacity.

---

10. Mix from one freezing

cylinder bleeds over to

the second cylinder.

a. The center draw valve seal is worn,

or improperly lubricated.

a. Lubricate properly and replace seal

every 3 months.

6-1, 9-1

Problem Probable Cause Remedy

Page

Ref.

Loading...

Loading...