6-6

OPERATING PROCEDURES

Model C722

Operating Procedures

6

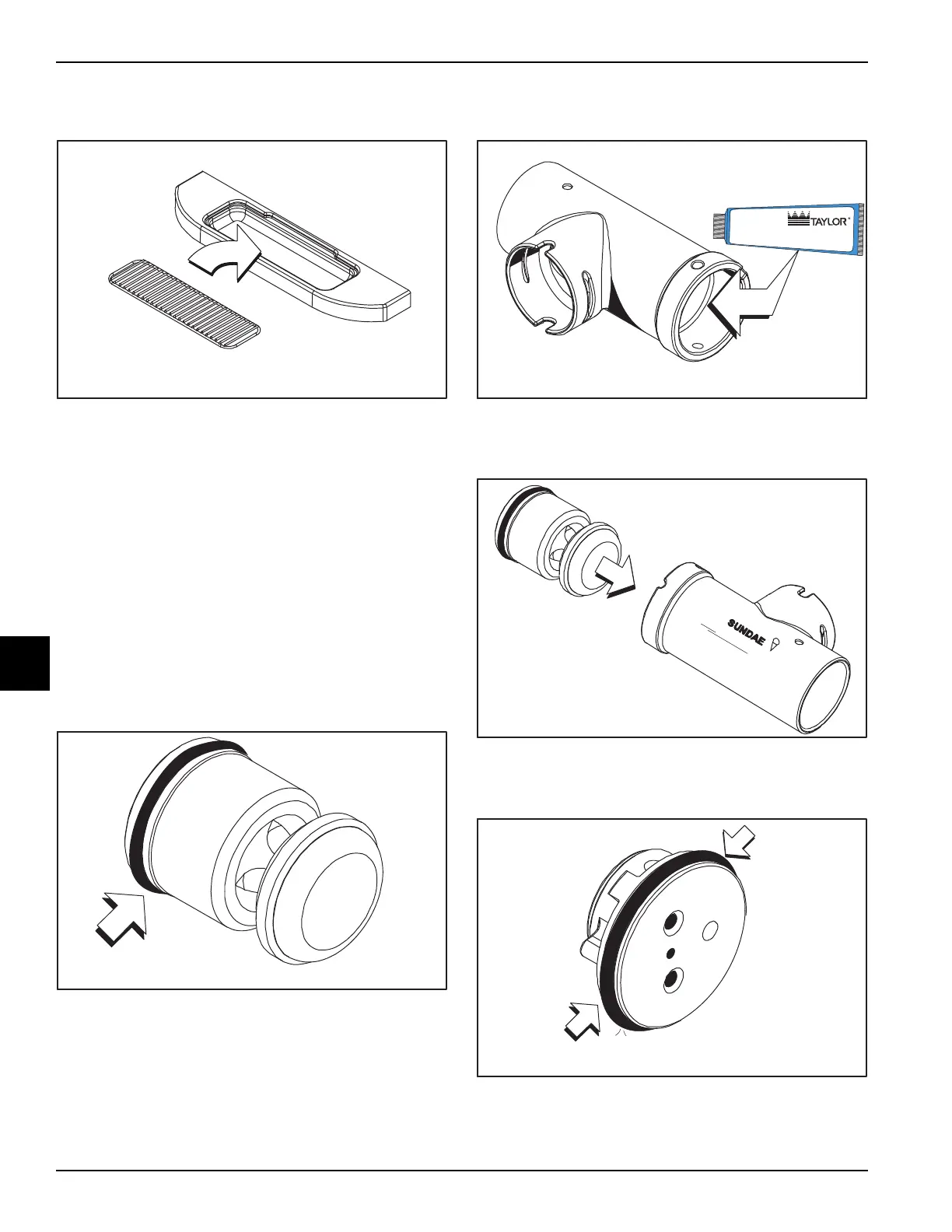

24. Install the front drip tray and splash shield under the

door spouts.

Figure 6-21

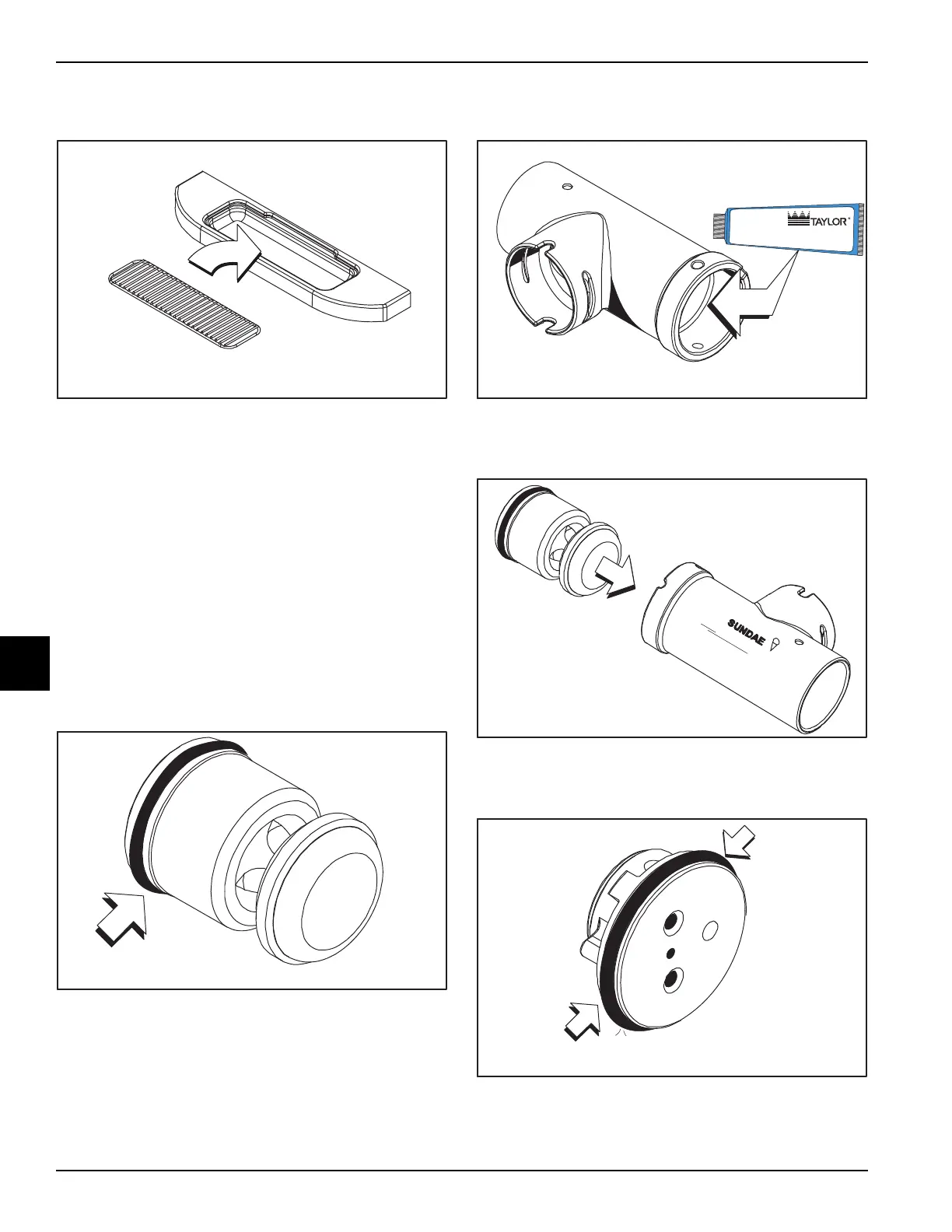

Mix Pump Assembly

1. Inspect the rubber pump parts. The O-rings and

gasket must be in 100% good condition for the pump

and the machine to operate properly. The O-rings

and gasket cannot properly serve their intended

function if nicks, cuts, or holes in the material are

present.

Inspect the plastic pump parts for cracks, wear, and

delamination of the plastic.

Replace any defective parts immediately.

2. Assemble the piston. Slide the red O-ring into the

groove of the piston. Do not lubricate the O-ring.

Figure 6-22

3. Apply a thin layer of lubricant to the inside of the

pump cylinder at the retaining pin hole end.

Figure 6-23

4. Insert the piston into the retaining pin hole end of the

pump cylinder.

Figure 6-24

5. Assemble the valve cap. Slide the O-ring into the

groove of the valve cap. Do not lubricate the O-ring.

Figure 6-25

15206

Apply the appropriate

Taylor approved food safe lubricant.

Loading...

Loading...