Section II – Pre-Installation Considerations

An important pre-installation consideration is the se-

lection of the ancillary equipment to be used with the

microLoad.net and how that equipment is interfaced.

(Table 6, page 16) which will assist in the assignment

of devices to the microLoad.net’s various I/O positions.

The Worksheet lists the available I/O points versus

possible devices or functions which may be applied.

By checking the appropriate boxes on the Worksheet

I/O map of your application is established. A sample

application starts on page 40.

Mechanical

In addition to the following, all previous warnings and

cautions should be reviewed before installation.

1. A solid vertical or slanted surface should be used

for mounting the explosion-proof microLoad.net

housing.

2. The location and the height of microLoad.net should

be selected to permit easy viewing of the display

and to provide convenient access to the keypad

by all users. See Figure 2 for dimensions of the

microLoad.net.

cover. For service, wiring and removal of parts the cover

must removed.

4. Conduit entry to the explosion-proof microLoad.net

is both through the bottom and sides. There are two

the unit.

5. In warm climates, microLoad.net should be shaded from

direct sunlight. The maximum external temperature

of the microLoad.net housing must not exceed 140°F

(60°C) to ensure that the internal temperature limit is not

exceeded.

Electrical

Note: See Appendix A for information regarding ATEX electrical

installation.

1. All DC wiring must be routed into microLoad.net

through the conduit entries located in the bottom of

the housing. Do not route DC and AC wiring through

the same conduit entry.

2. The DC signal wires must be multi-conductor

shielded cable of 18 to 24 AWG minimum stranded

copper.

at a minimum. Direct Ethernet connections between

computer and microLoad.net require a crossover

-

ration is used where the microLoad.net units are

networked through a hub or switch.

Note: The following recommendations are based on our knowledge

of the electrical codes. The local electrical codes should be reviewed

to ensure that these recommendations follow the local code. Also

installation manuals of all the equipment being wired into the micro-

Load.net should be reviewed for transmission distances and wire

recommendations.

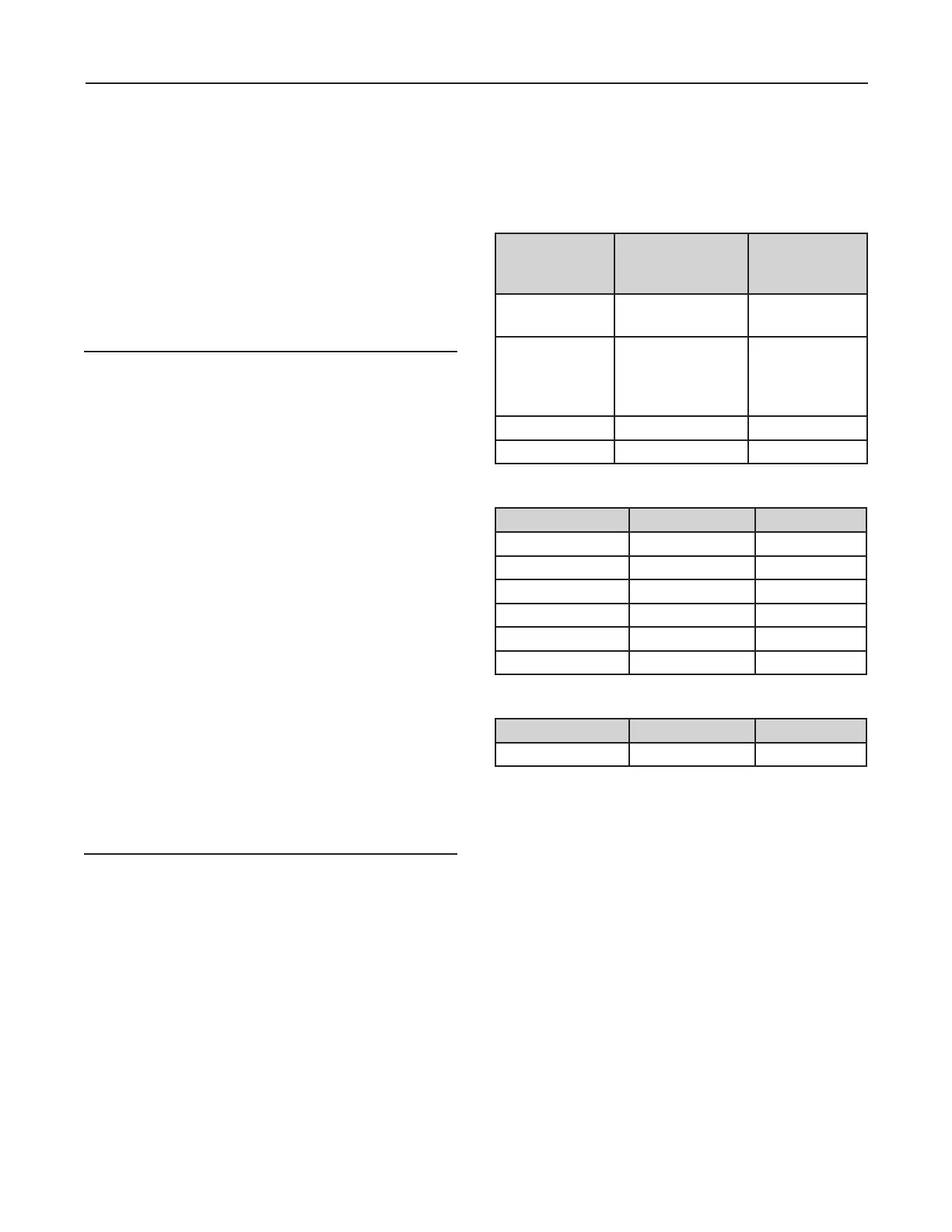

Table 1. Typical Wire Sizes

Equipment Number & Gauge

of Wire

Belden

Number or

Equivalent

Transmitters

4 / 18 Ga.

4 / 20 Ga.

9418

8404

Temp. Probes

Density and

Pressure

ransmitters 4 / 22 Ga.

8729

OR

9940

EIA-485 Comm 4 / 24 Ga. 9842

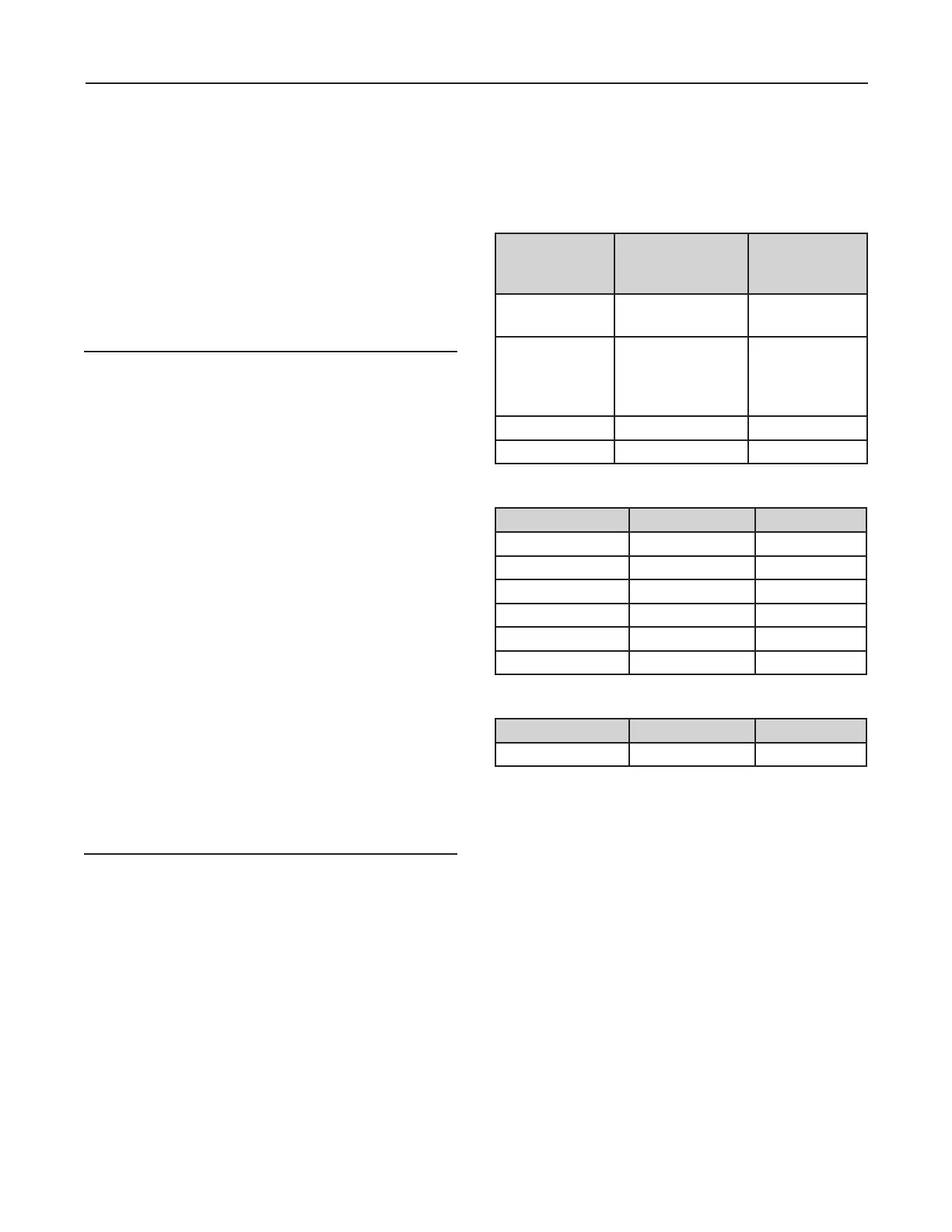

Table 2. Maximum Cable Length and Baud Rate (EIA-232)

Baud Rate Feet Meters

250 75

19,200 500 150

9,600 1,000

4,800 2,000 610

2,400 4,000 1,220

1,200 4,000 1,220

Table 3. Maximum Cable Length and Baud Rate (EIA-485)

Baud Rates Feet Meters

4,000 1,220

4. All AC wiring must be routed into microLoad.net

through the conduit entries located in the side of

the housing. Connectors sized for a maximum of 14

gauge wire, consult the local electrical codes for the

minimum AC wire size required for your application.

Do not route AC and DC wiring through the same

conduit entry.

5. All AC wiring should be stranded copper and must

comply with federal, state and local codes and

6. Two separate AC circuits must be provided from

the breaker panel. One circuit will supply isolated

power to the microLoad.net electronics (instrument

power). The second circuit will supply power to the

external devices.

7. For proper operation, the microLoad.net must be

Loading...

Loading...