Instruction manual ITEM TE550 S.p.A.

84/92

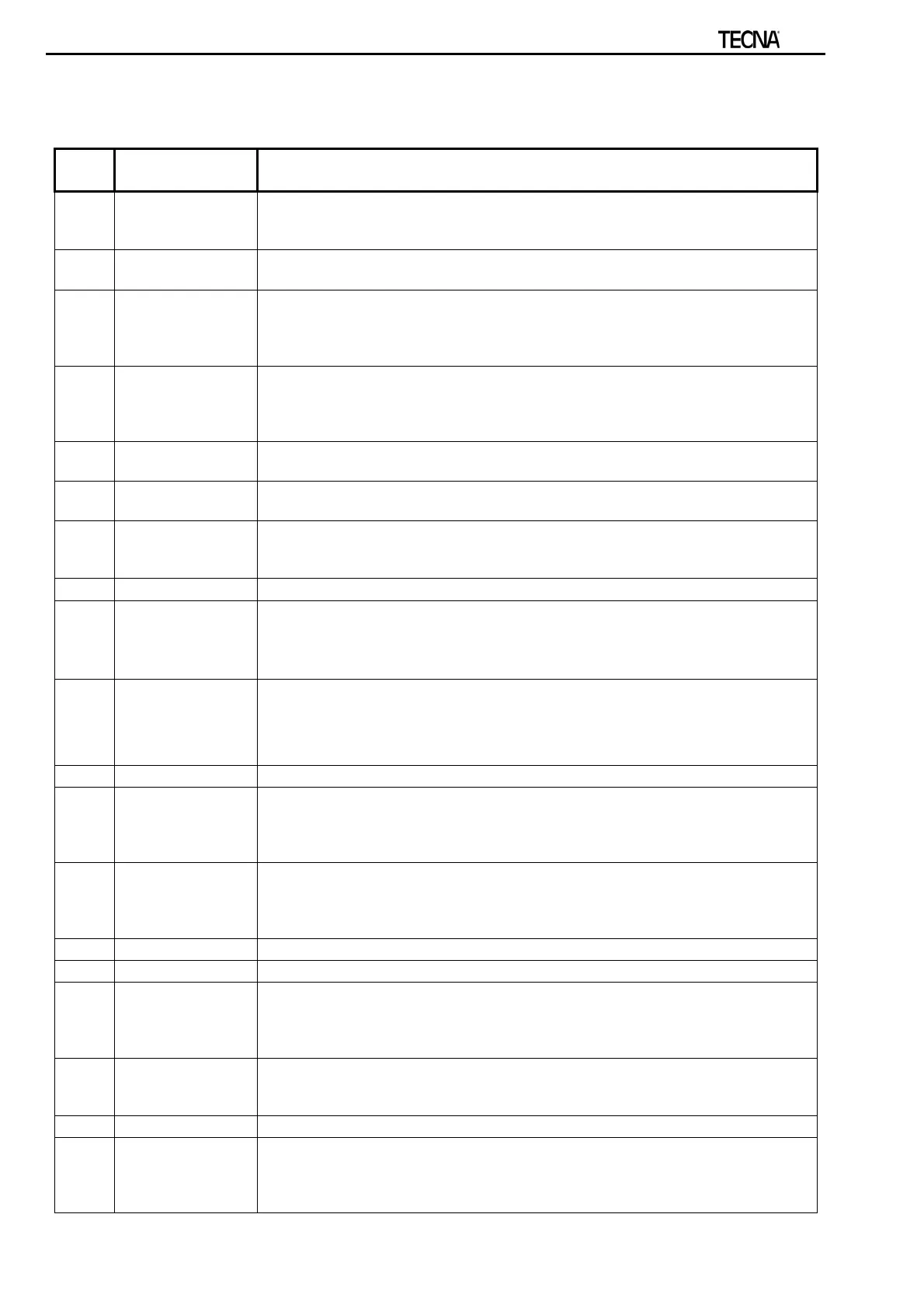

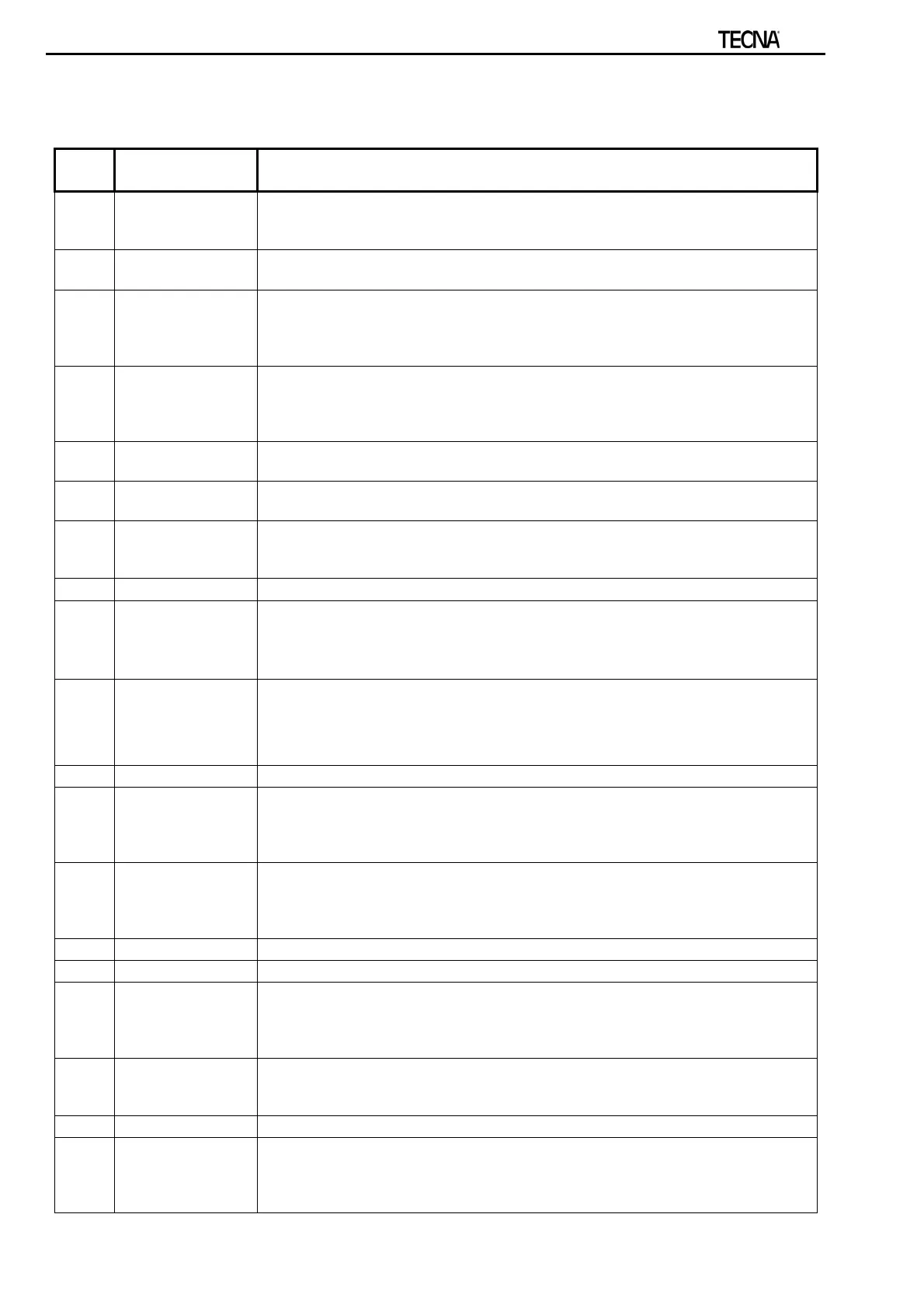

CHAPTER 14 - DESCRIPTION OF THE SIGNALS ON THE TERMINAL

BOARD

PIN NAME DESCRIPTION

1

3

VAC

This is the power supply of the control unit, which must be 24VAC. The power

supply transformer must be of at least 50VA and must power the control unit

only, to prevent any sources of interference.

2

GND Ground connection. Pay attention not to invert the wire with VAC (1-3) as

this could damage the control unit's fuses.

4

5

LOCK- / END-

LOCK+ / END+

This output is a polarized opto-electronic switch, Max 30VDC/10mA, and is

used to warn the user when a cycle ends if END CYCLE is selected; when in

LOCKED state, the control unit supplies a signal at output from the beginning of

the weld up to the hold.

6

7

WRONG -

WRONG +

This output is a polarized opto-electronic switch, Max 30VDC/10mA, and closes

if the set current limits are not met. The contact remains closed for the HOLD

and OFF time. In order to acknowledge all the signal activation cases, please,

refer to the relevant paragraphs.

8

COM2

Common for outputs with 0V reference. Connected to GND conforming to

regulation EN60204.

9

COM2

Common for outputs with 0V reference. Connected to GND conforming to

regulation EN60204.

10

TRIGGER

This is the SCR switch-on command output. The output is a rectangular wave,

amplitude of approximately 30V. The user must use trigger modules

manufactured by TECNA with opto-isolators.

11

COM1

Common for inputs with 24VDC reference.

12

RIC5

This input is used for calling the weld programmes directly from the outside.

This input is active closed on the COM1.

If the TE550 control unit is set to SEAM WELD mode, this input calls the

second weld current (POWER 3 or CURRENT 3 parameters).

13

14

15

16

RIC4

RIC3

RIC2

RIC1

These inputs are used for directly calling welding programs from the outside. In

order to call the programs correctly, these inputs must be enabled before the

cycle-start signal. Inputs are active when closed towards the common COM1.

17

COM1

Common for inputs with 24VDC reference.

18

AUX2

This input allows an external device to stop the weld cycle during the squeeze

stage. It may be used as interlocking input or to connect safety devices such

as, for instance, flow meters or pressure switches. The contact connected to it

must be the normally open type and activates closed on COM1.

19

START2 NO

To be connected to the microswitches of the cycle-start pedal. START2

determines the beginning of the work cycle of the second program selected

during the programming phase. This input is active closed on the common

COM1.

20

START2 NC

Currently this input is not used.

21

COM1

Common for inputs with 24VDC reference.

22

AUX

This input allows an external device to stop the weld cycle during the squeeze

stage. It may be used as interlocking input or to connect safety devices such

as, for instance, flow meters or pressure switches. The contact connected to it

must be the normally open type and activates closed on COM1.

23

START NO

To be connected to the microswitches of the cycle-start pedal. START

determines the beginning of the work cycle. This input is active closed on the

common COM1.

24

START NC

Currently this input is not used.

25

BIC1 NO

This input may be connected to the manual cycle-start buttons. The weld cycle

begins when BIC1 NO and BIC2 NO close simultaneously, or in sequence

within a max time of 0.5 seconds. This value was chosen conforming to

international safety standards.

Loading...

Loading...