10

codice 09MAXX001

versione EN

revisione 01

Use and Maintenance Manual

MaxX

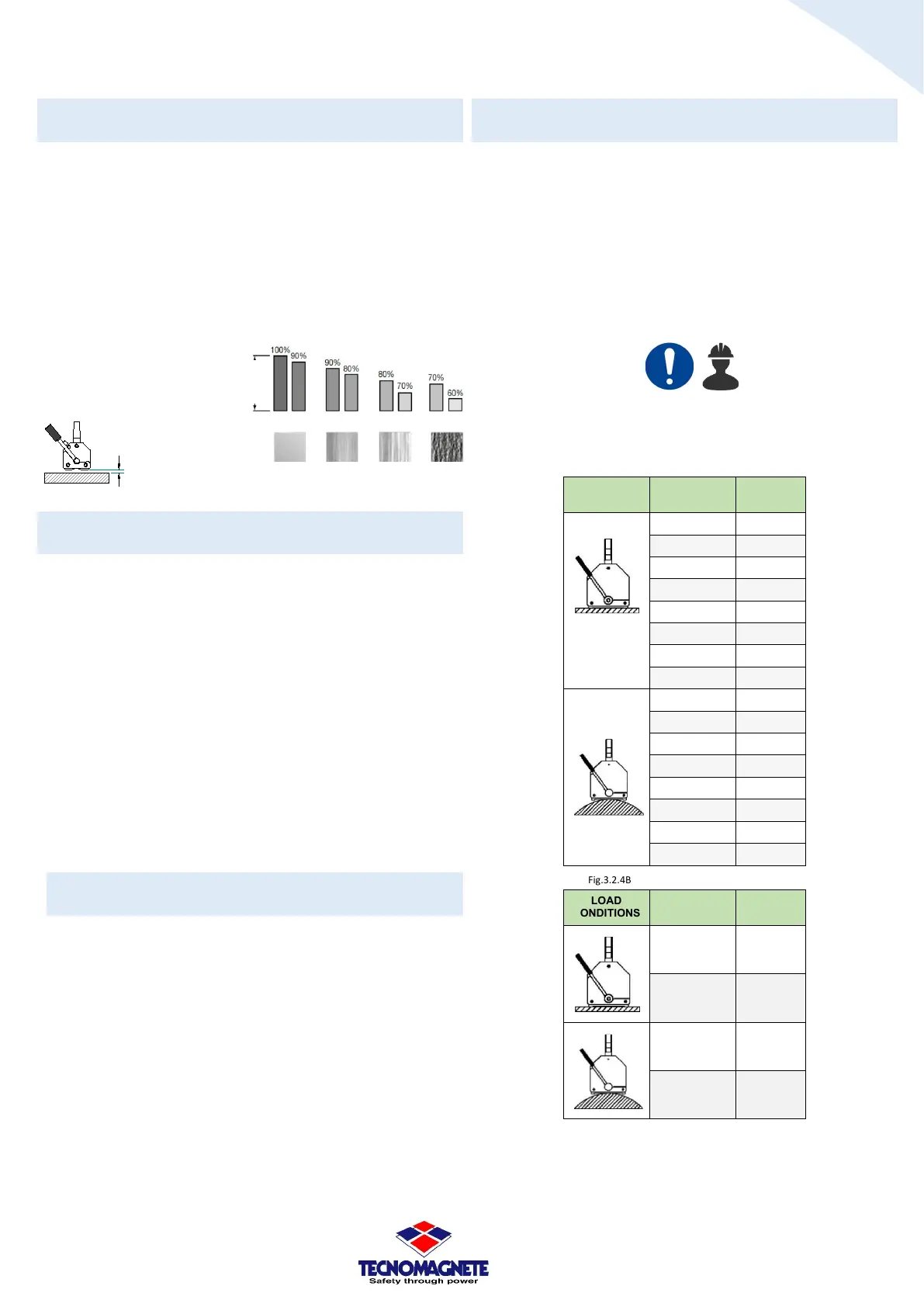

rectified fine milled medium milled rough

3.2.1. Air gap and roughness

The condition that guarantees the most efficient magnetic

attraction is obtained when the air gaps are reduced to a

minimum and there is a consistent surface of continuous

contact.

The worst results occur when there is a high air gap and a

minimum contact. A very important aspect is therefore the

degree of superficial roughness. A good contact surface

considerably decreases the air gaps thus obtaining an optimal

magnetic attraction force.

100% = rettificata

90 ÷ 80% = light milling

80 ÷ 70% = milling

70 ÷ 60% = rough

3.2.2 Contact surface

The magnetic attraction force is directly proportional to the

useful contact surface.

The superficial heat treatments of the material of which the load

is composed influences the physical structure as well as the

capacity of the load to absorb the magnetic flux.

The load made of annealed material is the best.

The load produced with hardened material does not

satisfactorily absorb the flow of time and the tendency to retain

a certain amount of magnetism when the MaxX has been

deactivated (DEMAG).

This amount of magnetism that remains on the load is defined as

magnetic residue and can create difficulties in detaching the

MaxX when it is deactivated (DEMAG). The magnetic residue

can be removed from the load by using a demagnetizer.

3.2.3 Type of material

Check the type of material to which the load is made to be

anchored magnetically. The technical characteristic

required by the material is its magnetic conductivity

(magnetic permeability). The technical characteristic

required by the material is its magnetic conductivity

(magnetic permeability).

1,0 mild steel

0,7 ÷ 0,8 alloy steel

0,5 cast iron

0,2 nichel

0 amagnetic stainless steel, brass, aluminium

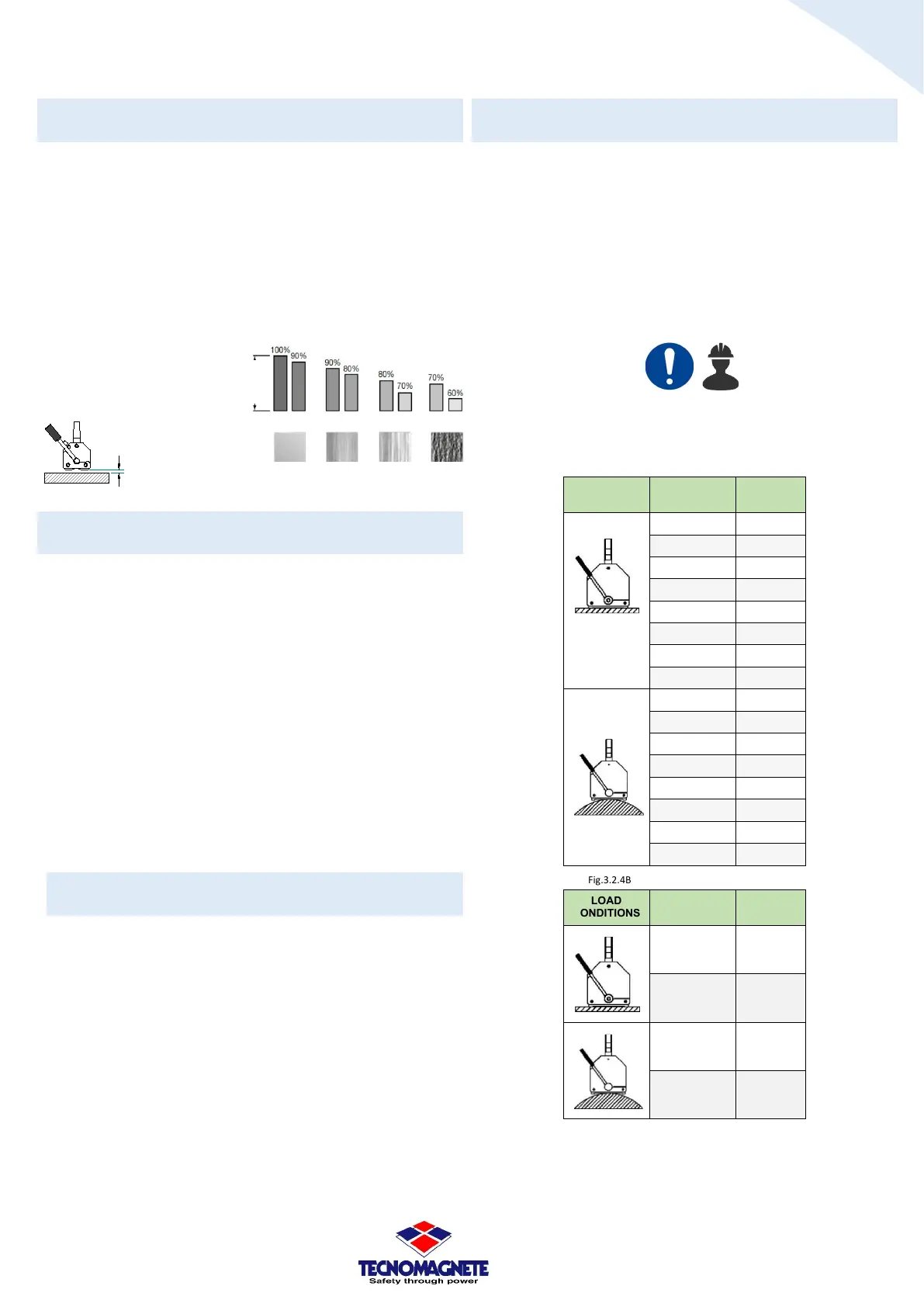

3.2.4 Material thickness

It can be hypothesised that the path of the magnetic flux,

inside a load to be anchored magnetically, consists of a

semicircle that starts from the center of a Pole (north) and

arrives at the center of the next one (south). If the load

fails to contain all the generated magnetic flux, the leaking

part is dispersed and does not contribute to the anchorage.

L’attrazione risulta dunque minore di quella che si potrà

avere quando tutto il flusso è assorbito da un carico di

spessore adeguato a contenerlo.

CHECK THE MINIMUM THICKNESS OF THE LOAD

TO BE LIFTED AS IN THE FOLLOWING TABLES

Fig.3.2.4A

LOAD

CONDITIONS

MODEL

MIN.

THICKNES

S

[mm]

MaxX 125 20

MaxX 250 20

MaxX 300E 20

MaxX 500 25

MaxX 600E 25

MaxX 1000 40

MaxX 1500 45

MaxX 2000 55

MaxX 125 10

MaxX 250 10

MaxX 300E 10

MaxX 500 15

MaxX 600E 15

MaxX 1000 25

MaxX 1500 30

MaxX 2000 35

Fig.3.2.4B

LOAD

CONDITIONS

MODEL

MIN.

THICKNES

S [mm]

MaxX TG150 8

MaxX TG300 10

MaxX TG150 8

MaxX TG300 10

contact

surface

T

=Air gap

Loading...

Loading...