9

codice 09MAXX001

versione EN

revisione 01

Use and Maintenance Manual

MaxX

N

S

N

S

N

S

N

S

S

S

N

N

4

1

2

5

3

S N

4

1

2

5

3

3.2

Basic principles of magnetic

clamping with MaxX

MaxX is born from TECNOMAGNETE experience in the

development of solutions for the handling of ferrous loads.

The MaxX described in this manual is a hand controlled magnetic

lifter able to move (lift, translate and deposit) ferromagnetic

material

(ex. Steel sheets, plates, rounds, common ferrous material).

MaxX is equipped with a ring-locking bracket and therefore can

only be used as a lifter when hung on a hook of the lifting and

translation means.

MaxX exploits the properties of permanent magnets to create a

magnetic field able to penetrate ferrous materials.

The activation is carried out by means of a lever which rotates a

core in which the permanent magnets are incorporated, so as to

obtain a magnetic flux which in the working phase passes

through the load to be manipulated and in the release phase is

short-circuited inside the lift itself.

The patented magnetic circuit of MaxX lifts conveys the flow

exclusively in the polar area, ie only where it is needed, without

dispersions and without affecting other adjacent loads.

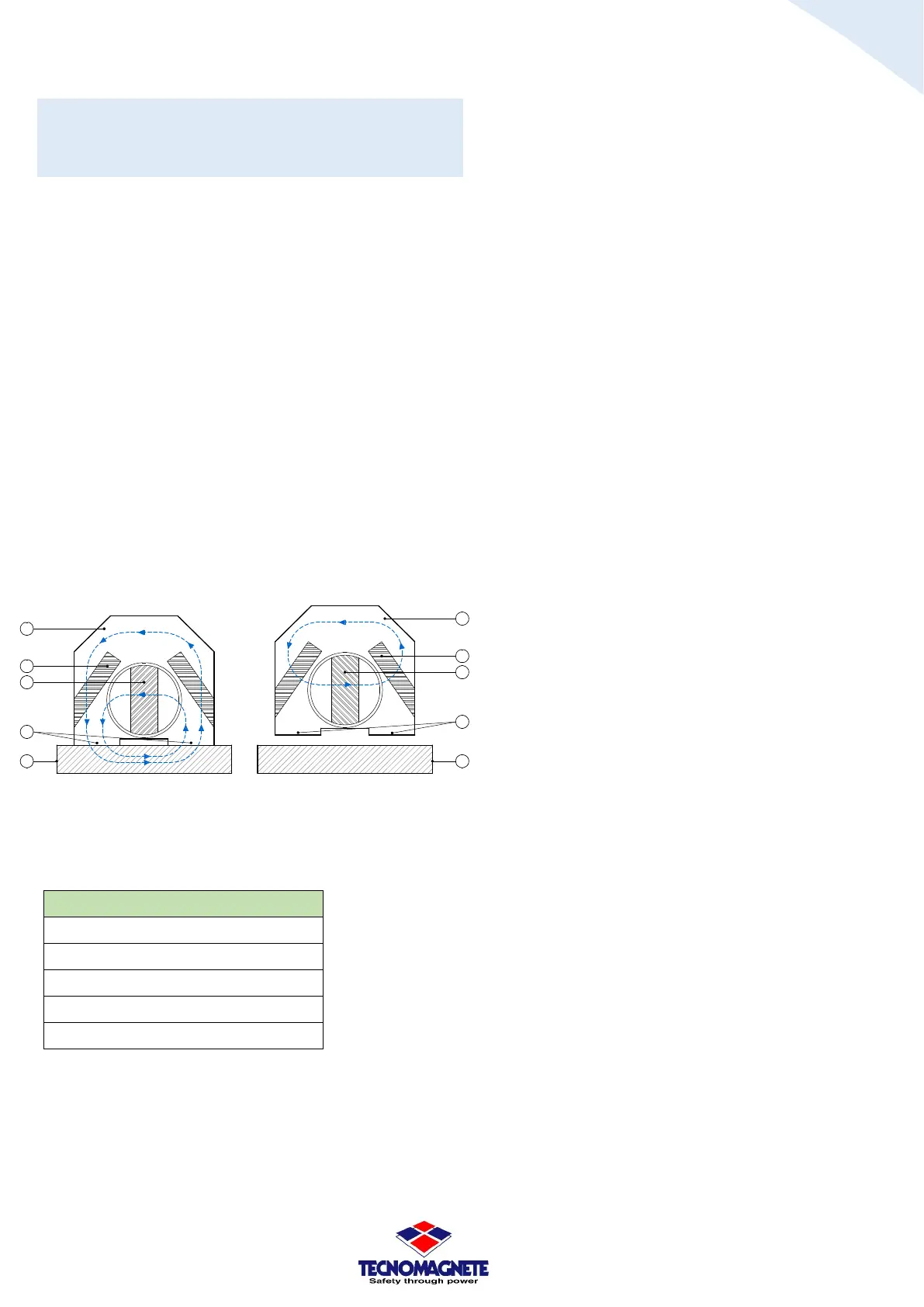

Fig.3.2A Fig.3.2B

Fig.3.2A Magnetization phase (MAG)

Fig.3.2B Demagnetization phase (DEMAG)

Fig.3.2C

Description

Static magneto-permanent core

①

Magneto-permanent nucleus invertible

②

③

④

⑤

The operating cycles of the MaxX are therefore:

- Fig.3.2A in MAG phase the invertible nucleus② is in

parallel to the static one ①. This generates a magnetic

field which, through the poles ③, is completed through

the piece to be anchored⑤.

- Fig.3.2B in the DEMAG phase, the two cores ① and

② are placed in series (rotation of 180 ° of the

invertible core②), constituting a magnetic field which

is short-circuited inside the frame.

Even if the magnetic field acts the same through non-

magnetic bodies (air-dust, non-ferrous materials in

general), maximum efficiency is obtained when the

poles of the same are in good contact with the surface

of the load.

The force curves (see paragraph 3.3), highlight the "fall"

of the anchorage force F (daN) of the lifter with the

increase of the air gap T (in mm), generated by any

"improper presences" between the aforementioned

poles and the load (calamine, foreign bodies,

depressions, protuberances, straps, etc.).

Therefore:

WE RECOMMEND NOT to place MaxX in very dirty or

highly deformed areas of the load. If this is not possible,

follow the performance indications given by the force-

air gap curve according to the characteristics of the load

to be lifted.

WE RECOMMENDED to clean the surfaces of the load

and the poles before placing the lift. If this is not

possible, follow the performance indications given by

the force-air gap curve according to the characteristics

of the load to be lifted.

WE RECOMMENDED, to periodically check the

mechanical condition of the poles ③ to ascertain the

good condition of flatness and the non-damage due to

possible mechanical accidents.

Loading...

Loading...